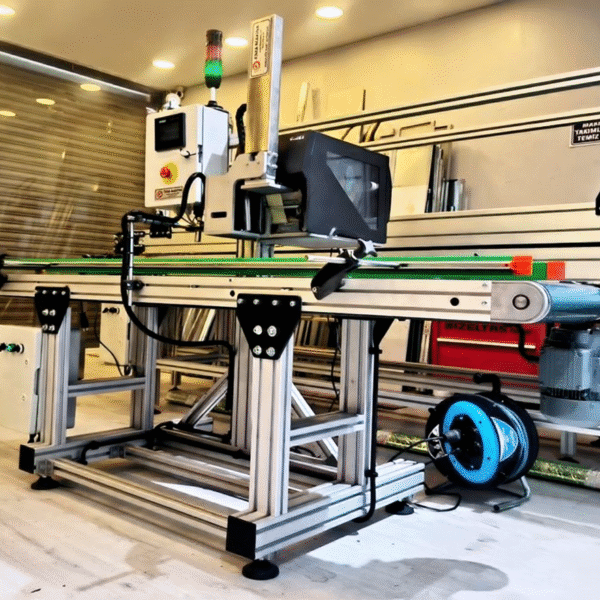

10-30 Pieces / Minute Automatic Bottle Labeling Machine

| Brand | ET-3 |

|---|---|

| Model Type |

ET-3 |

Tamçeki ET-3 10-30 Pieces / Minute Automatic Bottle Labeling Machine

This machine is a high-performance labeling system designed for fast and precise labeling in industrial production processes. Made of AISI 304 Cr stainless steel, it stands out for its durability and long-lasting use. It seamlessly performs the roll label application process on both the front and back surfaces of prismatic bottles and around the circumference of round bottles. Equipped with a PLC controlled system, this machine is supported by imported modules and has a labeling capacity of 800 pieces per hour.

Features:

-

Flexible Labeling Capacity: Supports various label sizes from 10 mm to 200 mm in width and 10 mm to 300 mm in length.

-

Fast Labeling: Increases production speed and efficiency by labeling 10-30 pieces per minute.

-

Modular Motors: Provides powerful and precise labeling with Step 5 NW Pacific Scientific motors.

-

Upper and Correction Belts: Equipped with 2 NW Step Motors, these belts ensure error-free labeling.

-

Carrier Belt Motor: Offers fast and efficient transport with a 380 Volt, 0.37 kW motor.

-

Synchronization: Provides perfect synchronization with an encoder, offering maximum accuracy during the labeling process.

-

Chassis: Durable Sigma Profile structure guarantees the machine’s robustness and long-lasting use.

-

Control System: User-friendly PLC control system allows for easy adjustment and monitoring.

-

Operating Voltage: Operates at 220 Volts, ensuring energy efficiency.

-

Operating Pressure: Ensures safe and efficient operation with 4-6 bar air pressure.

Advantages:

-

Versatile Use: Offers flexible labeling options for prismatic and round bottles, accommodating different packaging types.

-

High Efficiency: Accelerates your production processes with a labeling capacity of 10-30 pieces per minute.

-

Durable Material: AISI 304 Cr stainless steel chassis provides long-lasting use in challenging production environments.

-

User-Friendly PLC Control: Optimizes the labeling process with a user-friendly interface and easily adjustable PLC system.

-

Perfect Synchronization: Synchronized operation with the encoder system ensures error-free and accurate labeling.

Application Areas:

-

Food and Beverage Industry: Ideal for labeling bottled food and beverage products.

-

Chemical and Cosmetic: Provides precise and reliable labeling for chemical and cosmetic product packaging.

-

Packaging Industry: Suitable for fast and accurate labeling of different packaging types.

Technical Specifications:

-

Label Dimensions: 10 – 200 mm width, 10 – 300 mm length

-

Capacity: 10-30 pieces/minute (800 pieces/hour)

-

Modular Motors: Step 5 NW Pacific Scientific

-

Carrier Belt Motor: 380 Volt 0.37 kW

-

Operating Voltage: 220 Volt

-

Operating Pressure: 4-6 bar

-

Synchronization: Full synchronization with encoder

|

Description |

Explanation |

|

Label Dimensions |

10 – 200 mm. Width, 10 – 300 Length |

|

Capacity |

10-30 Pieces / Minute |

|

Modular Motors |

Step 5 NW. Pacific Scientific |

|

Correction Belts |

Step Motor 2 NW |

|

Upper Belt |

Step Motor 2 NW |

|

Carrier Belt Motor |

380 Volt 0.37 kW |

|

Synchronization |

With encoder |

|

Chassis |

Sigma Profile |

|

Control |

P.L.C. |

|

Operating Voltage |

220 Volt |

|

Operating Pressure |

4 – 6 Bar |

|

Positional Devices |

Model Y Wrapping Labeling Device |

Related products

160X240 Mm Label With Round Square Double Sided Bottle Labeling Machine

In stock

| Brand | OMS |

|---|---|

| Model Type |

160×240 mm |

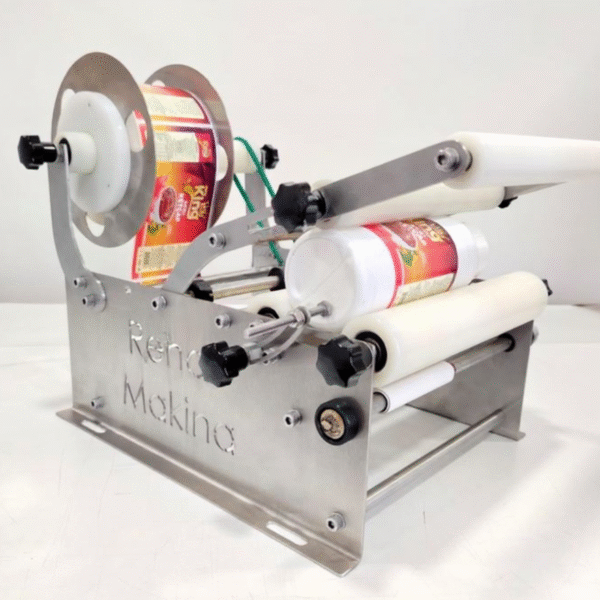

Domestic Production Stainless Body Desktop Labeling Machine

In stock

| Brand | Renas Makina |

|---|---|

| Model Type |

REM-M30 |

Printer Labeling Machine, Print and Paste Labeling Machine

In stock

| Brand | Fima Makina ve Otomasyon |

|---|---|

| Model Type |

FM1000ET Serisi |