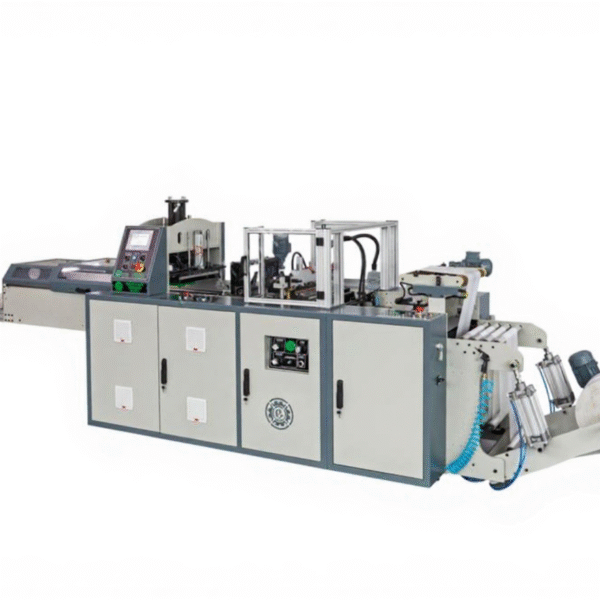

Automatic Roll Garbage Bag Machine

| Brand | Sura Machine |

|---|---|

| Model Type |

SM PZBP-300 |

Sura Machine SM-PZBP-300 Automatic Roll Garbage Bag Machine

Performance and Features:

-

Provides high efficiency thanks to computer-controlled automatic control, automatic counting, and adjustable counting alarm, saving labor and time.

-

The entire process from film wrapping to finished bag is fully automatic and completed in one go.

-

Domestic servo motor operates at a fixed length, is photoelectric tracking; has a precise and stable structure, and a photoelectric control system is used for feeding.

-

A hot cutting device and intelligent temperature control system are used to ensure the bag opening is closed tightly and smoothly.

-

The speed adjustment of the main motor is controlled by a frequency converter.

-

The rewinding process is controlled by PLC.

-

The discharge process is controlled by a frequency converter.

Model: SM PZBP-300

-

Bag making width (before folding): 400 – 800 mm

-

Bag making length: 100 – 2000 mm

-

Bag making speed: 60 – 160 pieces/minute

-

Maximum line speed of the film: 60 m/min

-

Bag making thickness: 0.008 – 0.02 mm

-

Bag making methods: Roll-connected flat bag

-

Power consumption: Approximately 8 kW

-

Total power: 15 kW

-

Machine size: 6500 × 1900 × 2200 mm

-

Machine weight: 2200 kg

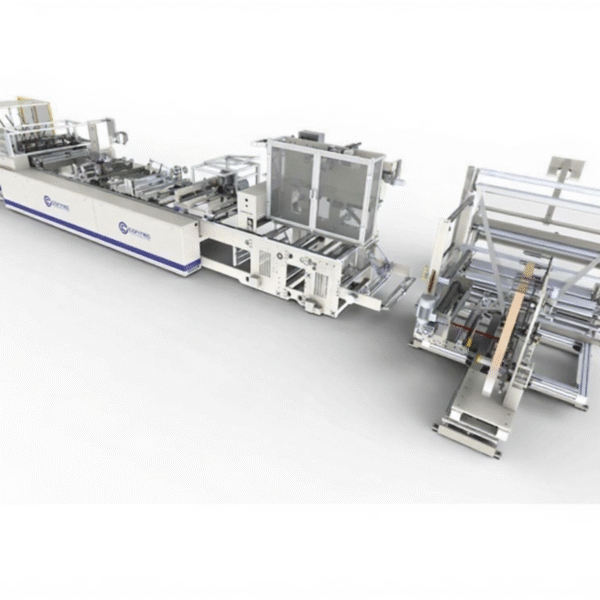

Automatic Pull Belt Bag Making Machine – Technical Details

-

Server part: 12 mm iron plate

-

Main controller of the machine: 7 inch touch screen HMI controlled

-

Power of the main motor:

1.5 – 6 kW AC motor + brake motor, easy reduction gearbox (maintenance) -

Main motor controller:

2.2 kW KEWO inverter controlled -

Bag making length controller:

1.3 kW Inovance servo motor × 2, surface rubber roller is 1020 mm -

Printing tracking:

From Megalosaurus to Panasonic -

Temperature control area:

2 areas -

Temperature control accuracy:

±1 °C -

Total heating power:

6 kW -

Film stopping system:

Finished stopping machine with SICK photoelectric belt (black film) -

Winding part:

550 W horizontal AC motor -

Folding:

— -

Filling motor control:

0.75 kW KEWO inverter controlled, linear potentiometer adjustable speed (analog) -

Film stopping machine:

SICK Germany correlation photoelectric -

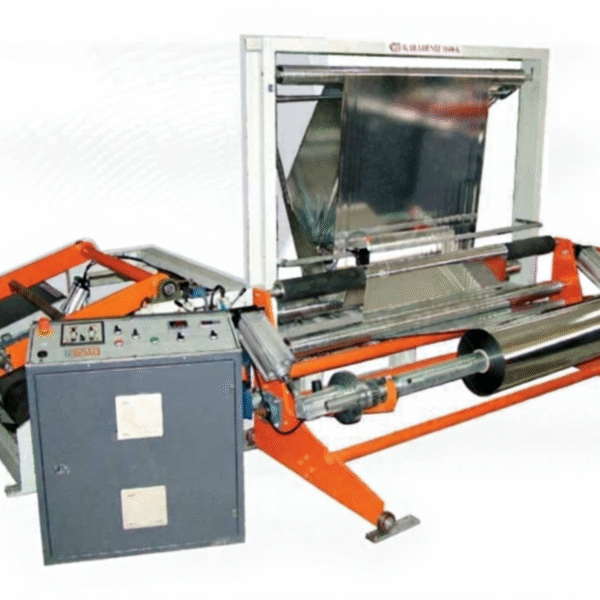

Film feeding frame type:

Roller feeding, manual turning valve controlled -

Film feeding motor:

2.9 kW INOVANCE motor -

Film feeding motor control:

2.9 kW KEWO inverter controlled -

Punch device control silencer:

— -

Pulling part:

— -

Pulling motor power:

0.75 kW vertical AC motor × 1 -

-

Pulling Motor Control:

0.75 kW KEWO inverter controlled. One is used for speed adjustment with a Panasonic photoelectric switch, the other is used for proximity switch controlled cylinder.

Rewinding Part

-

Rewinding Controller:

CITIC PLC and 7 inch touch screen controlled, Taiwan Delta 24V switching power supply (100 W) -

Rewinding Motor Power:

0.75 kW AC motor × 2 -

Winding Motor Controller:

0.75 kW KEWO inverter controlled × 2, linear potentiometer adjustable speed (analog) -

Sound Control Change:

0.75 kW Inovance servo motor + planetary reducer

Electrical Equipment

-

Contactor: Schneider (France)

-

Intermediate Relay Brand: Schneider (France)

-

Solenoid Valve and Cylinder: AIRTAC

-

Sensor Brand: China / Taiwan – Megalosaurus, FOTEK

Electrical Configuration

-

PLC Brand: CITIC from China

-

Touch Screen Brand: CITIC from China

-

Inverter Brand: KEWO from China

-

Motor Brand: Wuhu Delicatessen

-

Servo Motor System Brand: YENLIK from China

-

Contact Brand: SCHNEIDER from France

-

Button Brand: Made in China

-

Photoelectric Brand Feeding: HASTA (Germany)

-

Photoelectric Brand Tracking: Megalosaurus

-

Switching Power Brand: Taiwan Delta

-

Temperature Control Device Brand: AIRTAC

-

Proximity Switch Brand: FOTEK from China / Taiwan

-

Electromagnetic Valve Brand: AIRTAC

-

Cylinder Brand: AIRTAC

-

Precision Pressure Regulation Valve and Rotary Joint Brand: AIRTAC

-

All Pneumatic Parts Rewinding – Components: AIRTAC

-