Wood Chip Wood Grinding Pelletizing Facilities

| Brand | Starmax |

|---|---|

| Model Type |

Biostar |

Wood Chip Wood Grinding Pelletizing Facility

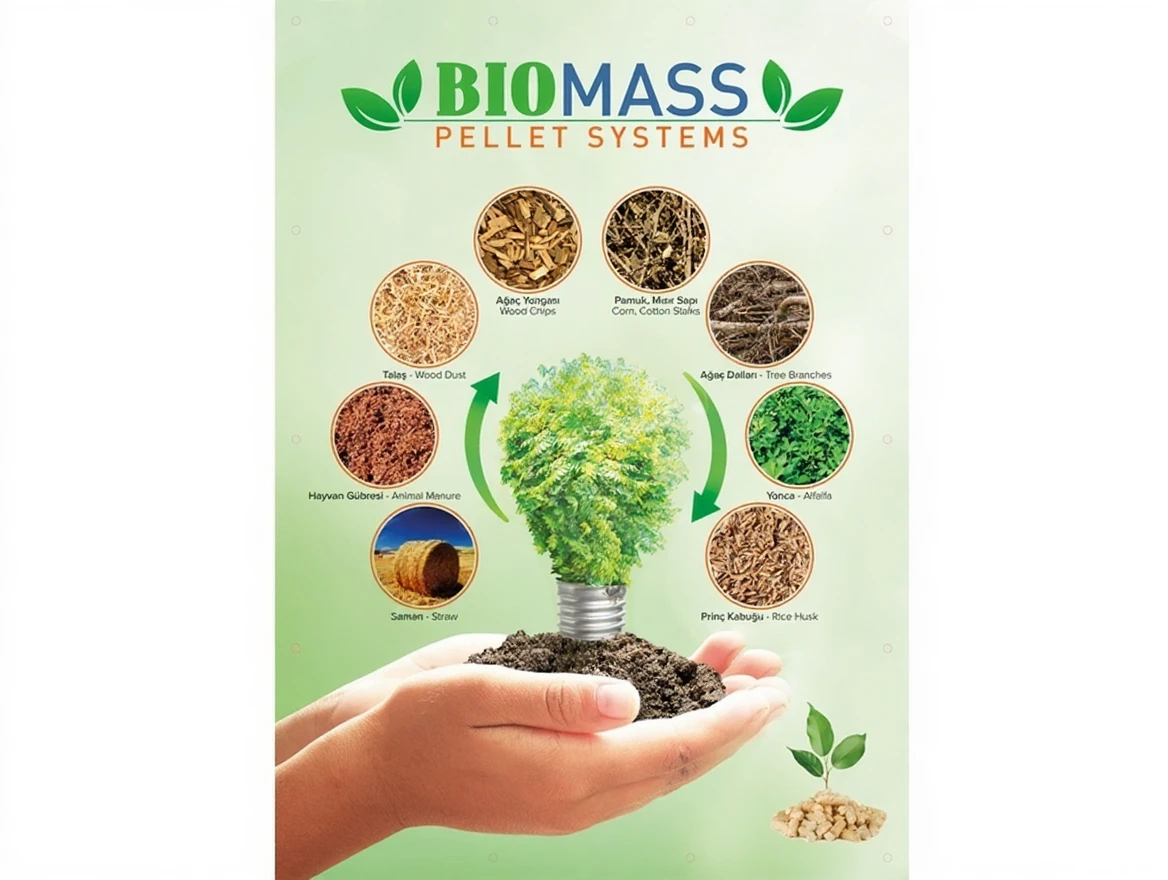

The wood and chip pelletizing process is a process that makes biomass waste

(waste such as chips, wood chips, tree branches, wood, cotton stalks, corn stalks, sunflower stalks) easier to store and more efficiently usable in heating systems.

Wood and chip pellets produced with biofuel pelletizing technology can be used as a high value-added fuel source in home heating systems, industrial heating, and energy production. This technology is considered an important method for providing an environmentally friendly energy source.

The advantages of wood and chip pellets can be listed as follows:

-

Ease of Storage

-

Reduction of Transportation Costs

-

Being an Ideal and Clean Fuel Source

-

Higher Fuel Efficiency

-

Waste Management

Bio-pellet facilities provide a sustainable solution for waste management and energy production. Wood pellets are often preferred in pellet stoves and boilers.

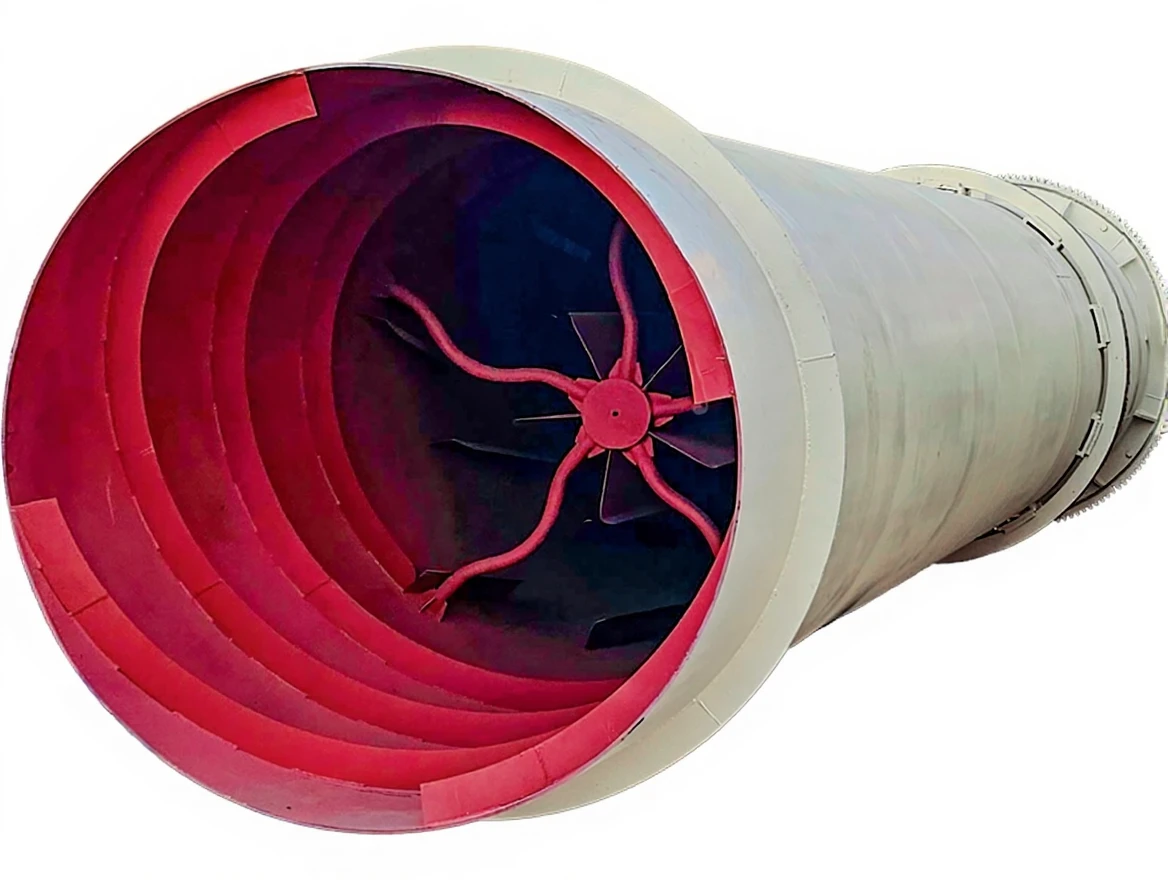

The Starmax bio-pellet facility consists of drying, grinding, dust removal, mixing, pelletizing, cooling, screening, transporting, and packaging processes. The machines and equipment to be used may vary according to customer needs.

✔ Biofuel pellets for pellet stoves & boilers

✔ Wood pellet machine & Chip pellet machine

✔ Biomass pellet press & Wood pellet production line

✔ Pine pellet production factory

✔ Wood chip pellet production facility

✔ High energy pellet fuel production

✔ Pine pellets & Beech pellets & Alder pellets & Spruce pellets & Fir pellets

✔ Sunflower stalk pellets & Corn stalk pellets & Cotton stalk pellets

✔ Waste pellets & Olive pomace (prina) pellets

✔ MDF pellets & Chip pellets

✔ Natural cat litter pellets

✔ Tea pelletizing