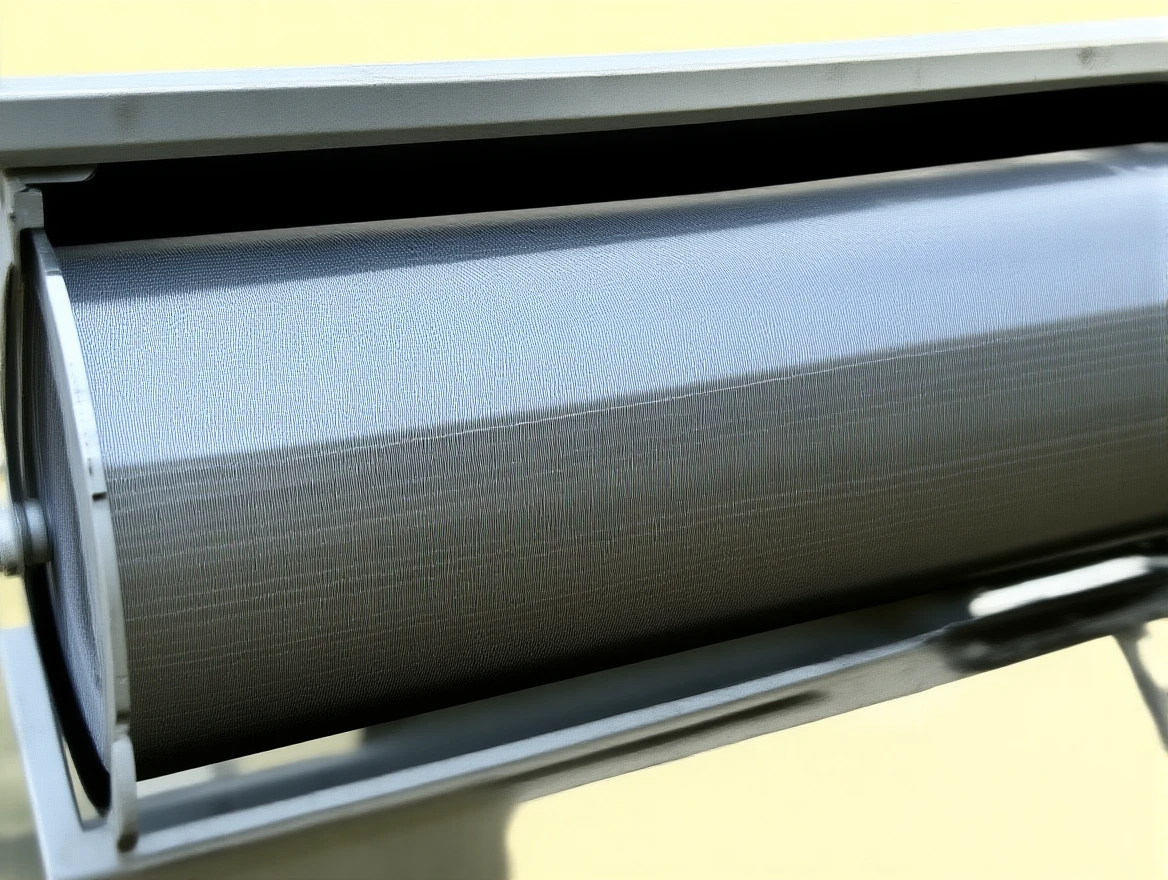

Milk Processing Drum Screen

Rotary screen type fine grids are equipment used for very fine separation (250-2000 microns), also known as drum screens. The water and wastewater flowing inward through the cylindrical screen surface are filtered, while solid materials are retained inside the screen and collected by the surface cleaning system and sent to the collection chamber.

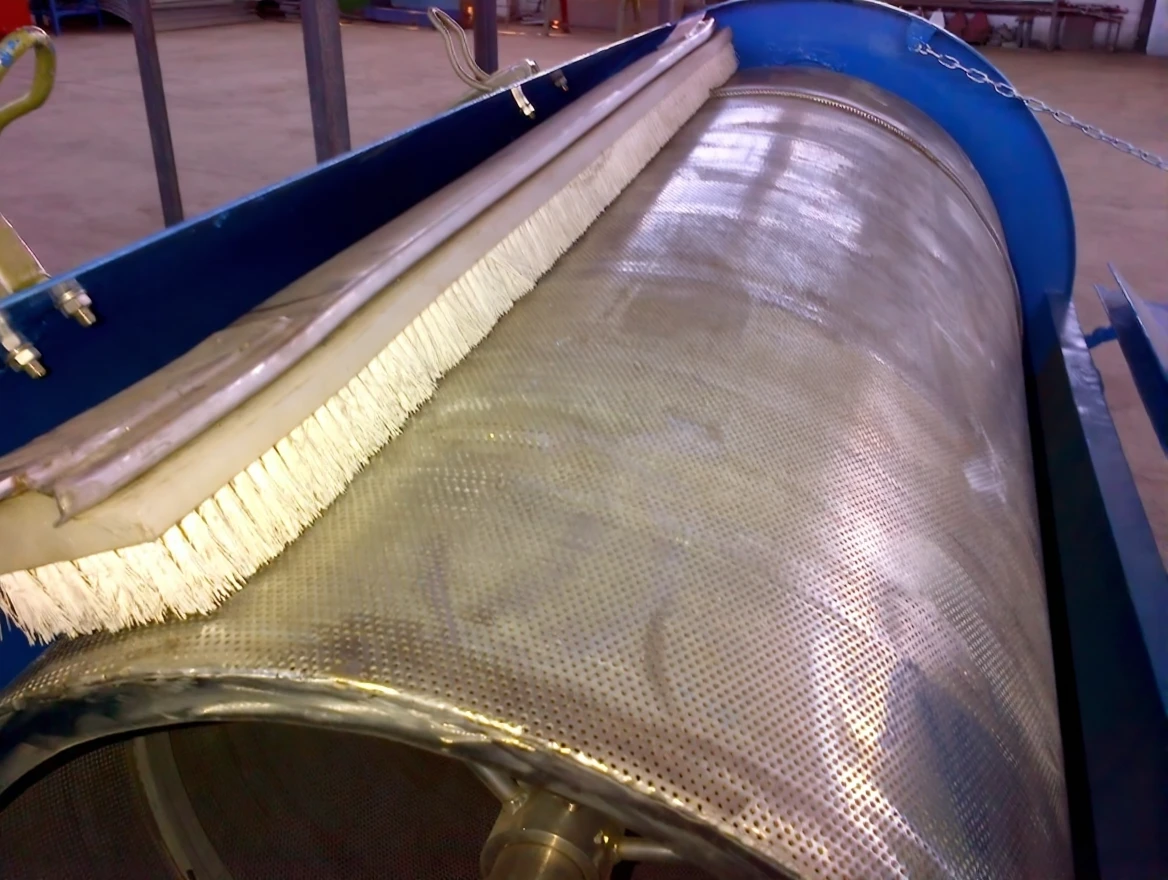

In drum screens that can also be manufactured with external flow, water and wastewater come from the outside to the screen surface, and after solid materials are retained on the surface, they are collected and removed by a cleaning brush. Rotary (drum) screens can be produced optionally from stainless steel, galvanized, or carbon steel coated with suitable quality epoxy paint.

Areas of Use for Tidap Rotary Drum Screen;

-

Wastewater Treatment Plants

-

Feedlots

-

Slaughterhouses and Abattoirs

-

Dairy and Dairy Product Facilities

-

Fruit and Vegetable Washing – Processing

-

Recycling – Recovery Sector

-

Mining

-

Processes requiring solid-liquid separation

-

Used in situations where process losses need to be prevented.

-

Screen material in AISI304 / AISI316 imported/local options

-

Inward/outward flow types according to process needs

-

Motor-reducer

-

Includes water tank, automatic cleaning system.

-

It is a maintenance-free, long-lasting process equipment.