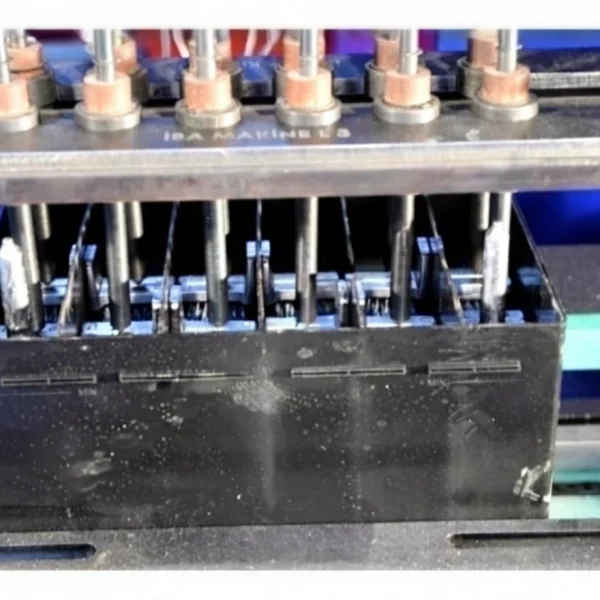

Battery Initial Charge (Formation) Rectifiers

| Brand | Redartı |

|---|---|

| Model Type |

R-AM-001 |

Category: Battery Manufacturing Machines

Description

Battery First Charge Rectifiers are devices used to charge the battery correctly when a new battery is purchased or when it is not used for a long time.

The Redartı Battery initial charge device is a special rectifier developed for the first charge process of batteries that take a long time. It shortens the charging time with advanced power control technique based on microprocessor and charges more batteries at the same time than its counterparts. Each program consists of steps where different durations and current values can be set. The user can change these step values, charge for a certain period with a current, and continue with a different charging time with a different current value after the period. By inserting steps with a current value of zero between the steps, batteries can be rested for the set time. Moreover, the device prevents batteries from being damaged during charging.

Display of actual parameters during charging

Display of end values at the end of charging

Display of total Ampere hour at the end of the process

Recording the last 10 errors

Viewing the end values of the last 45 charges retrospectively

Space Saving (60% smaller dimensions than 50 Hz systems)

Lighter (60% lighter aiming to reduce transportation and storage costs)

Charges with a more linear current and does not damage the internal structure of the battery.

Creates less water loss.

Charges with less electricity consumption, resulting in less CO2 emission.

Not affected by changes in mains voltage.

Charges with less current draw from the mains and uses thinner cables for mains connection.

Charges the battery with less heating during the charging process.

Lower ripple factor than Wowa systems (Wowa %48 / HF %2)

Automatic stop in case of battery connection error

Display of end values at the end of charging

Display of total Ampere hour at the end of the process

Recording the last 10 errors

Viewing the end values of the last 45 charges retrospectively

Space Saving (60% smaller dimensions than 50 Hz systems)

Lighter (60% lighter aiming to reduce transportation and storage costs)

Charges with a more linear current and does not damage the internal structure of the battery.

Creates less water loss.

Charges with less electricity consumption, resulting in less CO2 emission.

Not affected by changes in mains voltage.

Charges with less current draw from the mains and uses thinner cables for mains connection.

Charges the battery with less heating during the charging process.

Lower ripple factor than Wowa systems (Wowa %48 / HF %2)

Automatic stop in case of battery connection error

Easy Installation

Long Working Life Fully Automatic

Operation Program

Turkish Control Panel

Intelligent Error Tracking System

Control of All Process Parameters

Battery Temperature Measurement

Visual Error Messages

Independent Selection of 20 Different Programs

Charge Channels Automatically Stop at the end of the process

Automatic Charging Cut-off in Error Conditions

Charge Technique Extending the Life of the Battery High Efficiency

Easy Provision of Low Maintenance Requirements

Standard Parts

Silent Operation

Eco-friendly Design

Energy Saving System

Aesthetic Appearance

Battery Overheat Protection

Continuing from Where it Left Off After Power Outages

Long Working Life Fully Automatic

Operation Program

Turkish Control Panel

Intelligent Error Tracking System

Control of All Process Parameters

Battery Temperature Measurement

Visual Error Messages

Independent Selection of 20 Different Programs

Charge Channels Automatically Stop at the end of the process

Automatic Charging Cut-off in Error Conditions

Charge Technique Extending the Life of the Battery High Efficiency

Easy Provision of Low Maintenance Requirements

Standard Parts

Silent Operation

Eco-friendly Design

Energy Saving System

Aesthetic Appearance

Battery Overheat Protection

Continuing from Where it Left Off After Power Outages