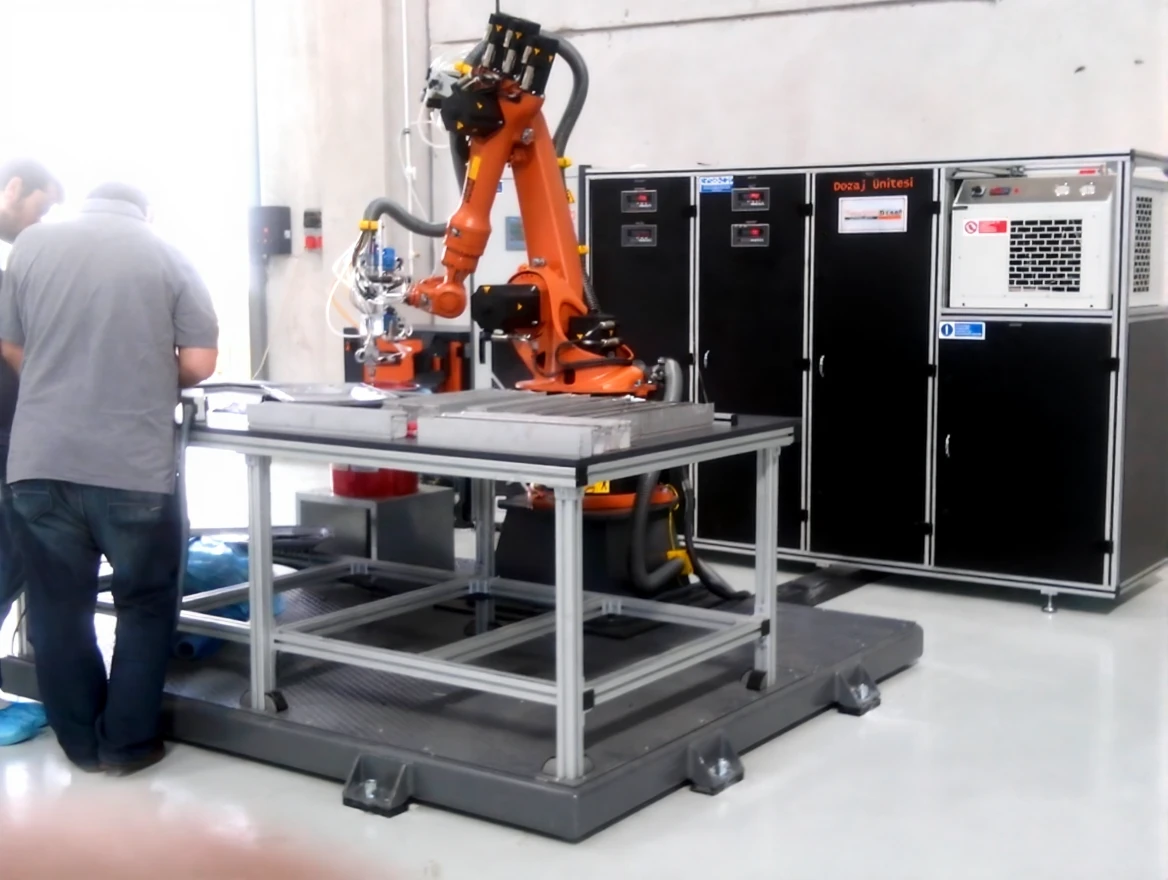

Polyurethane Liquid Gasket Pouring Robot

| Brand | Teknofinsteel |

|---|---|

| Model Type |

Robosim PU 0735 |

POLYURETHANE LIQUID GASKET POURING ROBOT GENERAL INFORMATION

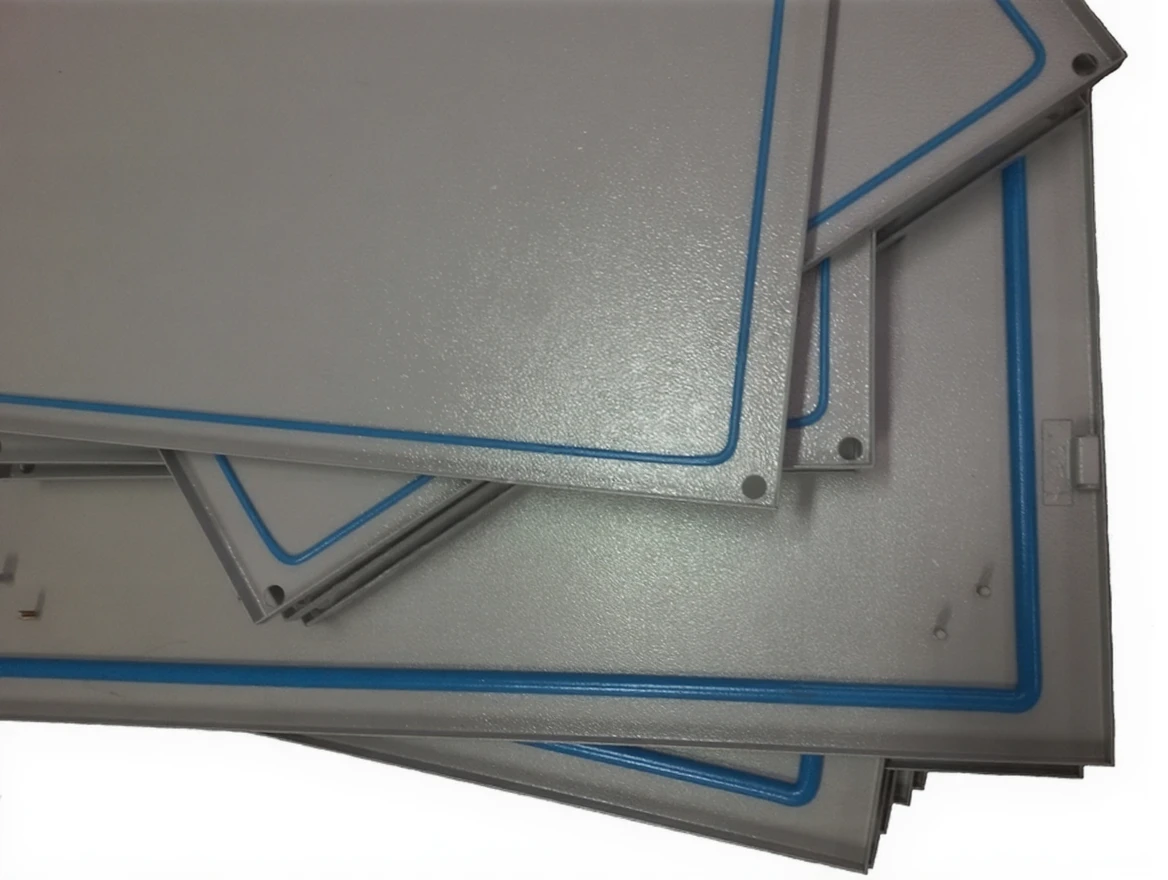

Rubber foam gasket sealing Machine

Pu sealing Machine gasket Machine

Pu gasket dispensing Machine

Polyurethane gasket seal Machine

Pu gasket sealing Machine

Pugasketing Machine

Pu polyurethane foam sealing

Best pu gasket sealing Machine

Automatic sealing foam

Designed for high precision with a robust structure and high work safety, a 3-axis linear robot. Operated with a CNC keyboard, the communication menu-based system is used to run the program and control the machine.

Operational data is mounted on a central dosing and mixing control unit, displayed on a multifunctional CNC controller screen.

The system is designed for applications involving high-speed processes in liquid sealing.

The central unit integrates control mixing and dosing with motion control mounted in the system.

The chassis section is made of robust welded steel profile material or aluminum profiles imported from Germany.

It is mounted to the ground with adjustable vibration receivers.

Machines operating at high speeds are delivered with ground anchoring leveling feet.

TECHNICAL SPECIFICATIONS

• Mechanically equipped with high torque dynamic AC servo drives and backlash-free reducers.

• Sliding speed: 15 m / min

• Acceleration: 10 m/s

• Position accuracy: + / – 0.05 mm

• Load capacity: 60 kg

• Chassis section: different structure according to 2 or 3 components.

• Industrial class coating, RAL 7035 (light gray) and RAL 9001 (black)

• Electrical system: according to EN 61439/1-2 standard

• Power supply: 3 x 400 V, 50 Hz or 60 Hz or according to country specifications

• Installed electrical power approximately 4 kW.

• Average power consumption approximately 1.5 kW

Features of the Polyurethane Gasket Pouring Machine:

• Robosim 0735 800 x 600 x 300 mm (x / y / z)

• Robosim 0735 2,500 x 2,200 x 300 mm (x / y / z)

• Optional Y axis 1,250 or 1,500 mm

• Robosim 0735 2,500 x 1,000 x 300 mm (x / y / z)

• Robosim 0735 3,000 x 1,000 x 300 mm (x / y / z)

• Optional Z axis 150 or 500 mm

• Robosim 0735 2,000 x 1,000 x 300 mm (x / y / z)

• Provided by the main switch

• Emergency stop function

• Automatic washing and drying system for emergency stops

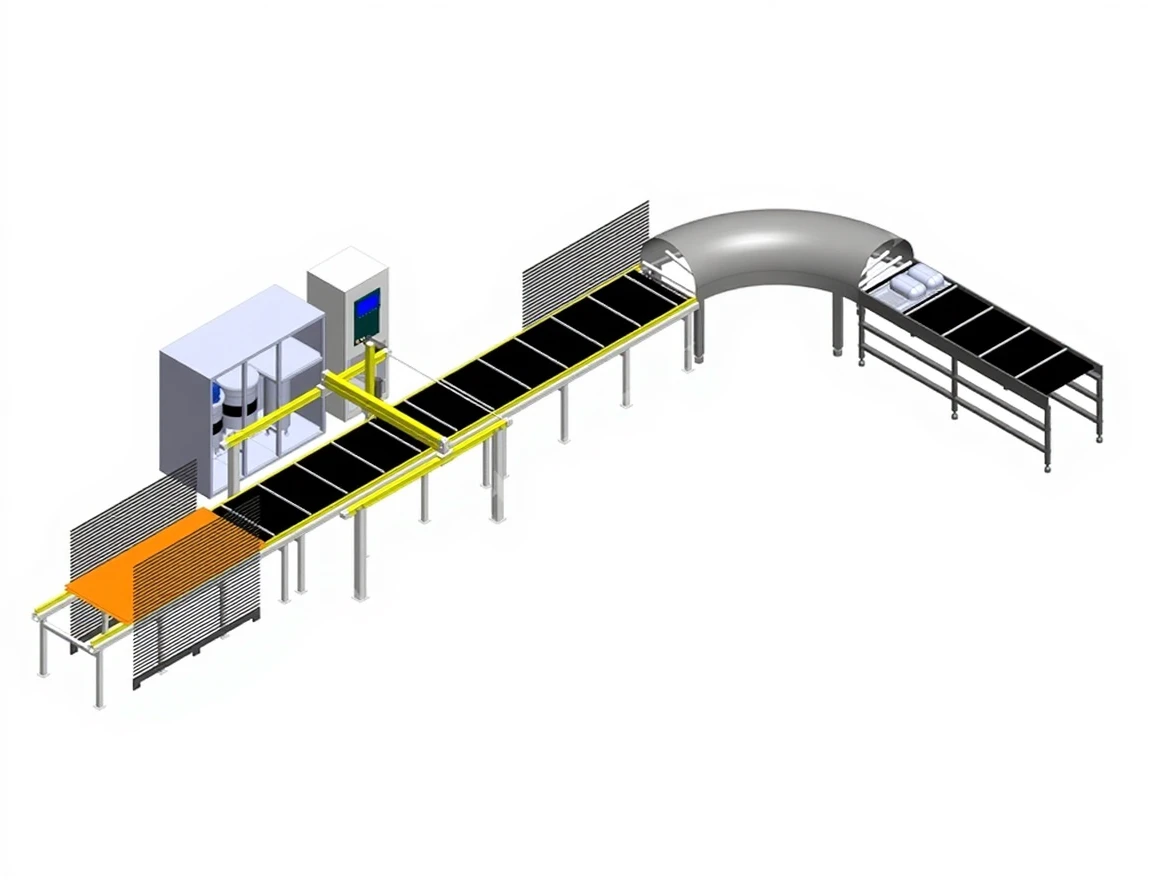

• For continuous production, polyurethane liquid gasket application with two stations and no downtime for material indexing

• High-tech produced and easy-to-use polyurethane liquid gasket machines.

• The gasket pouring machine can create a recipe for excellent production tasks for the user.

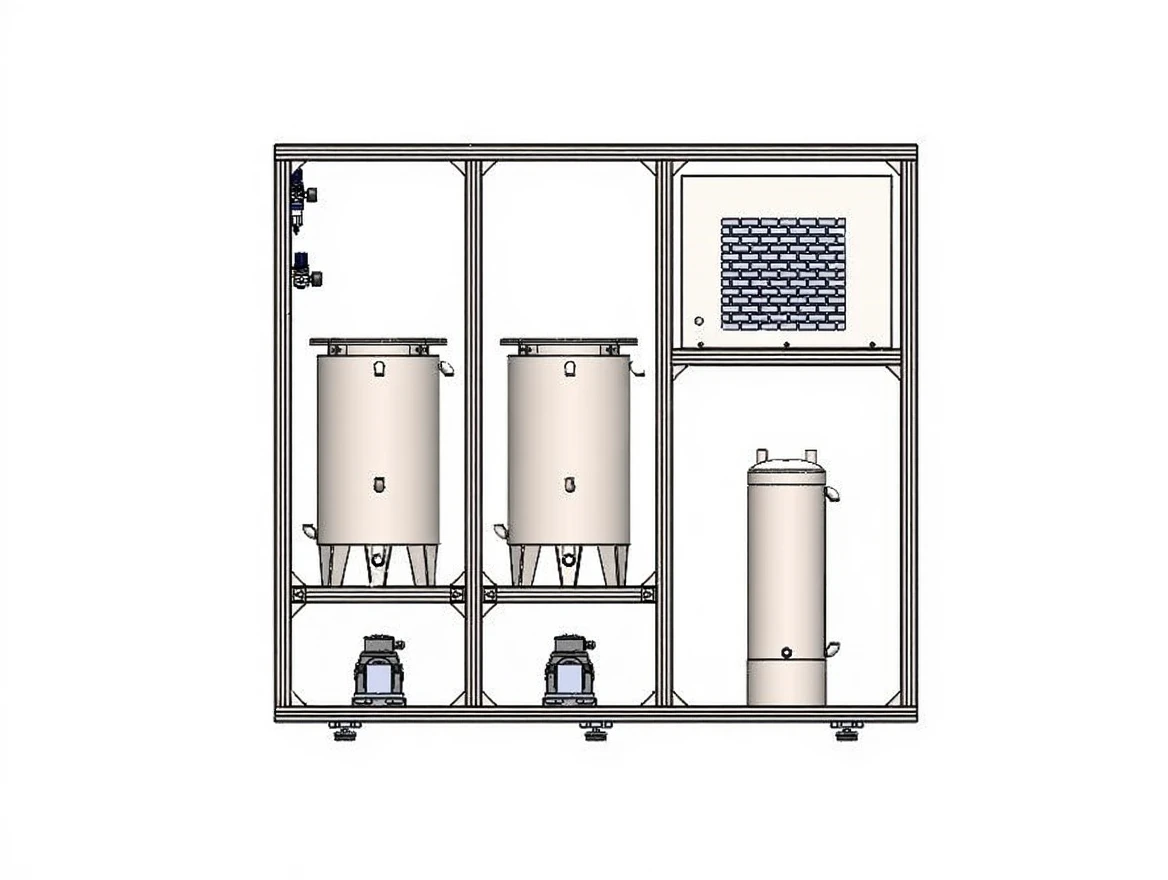

• Pressure vessels are specially produced from double-walled, chrome-nickel steel.

• Equipped with a 19 lt tank for cleaning agents, safety valve, and minimum level monitoring.

• Polyol tanks are driven by a rotary mixer reducer, the mixer has a helical structure at 22 rpm speed.

• Chiller system is available for heat control (18-25 C) in double-walled tanks.

• Optional automatic filling control system

• Hose Package

• Precision gear pumps

• Mixing head

• Application valve system

• Rinsing and particle ejection system

• Spare Parts Packages

• Compressed Air dryer

• Transport, installation and training

• Output amount from 0.1 to 30.0 g/s, other output amounts can be provided upon request.

• Viscosity processing range: DM 50: 100-50,000 mPas, other viscosities can be provided upon request

• Compressed air: 6 bar

• Total weight: 300 kg

• With all electrical and pneumatic connection lines and compressed air system

• More technical information for the polyurethane liquid gasket pouring machine is provided upon request.

* For more information [ URL HIDDEN ];

Related products

40-50 Pieces/Minute Ventilation Clip Assembly Machine (Horizontal Type)

In stock

| Brand | Parola Makina |

|---|---|

| Model Type |

PM-HKO-V.01 |

800-3000 Gr/Sec High Pressure Polyurethane Injection And Dosing Machine

In stock

| Brand | Polymix |

|---|---|

| Model Type |

P-PM006 |

Electrical Vibration Surface Processing Machine

In stock

| Brand | Serel Vibrasyon |

|---|---|

| Model Type |

SRL E Serisi |