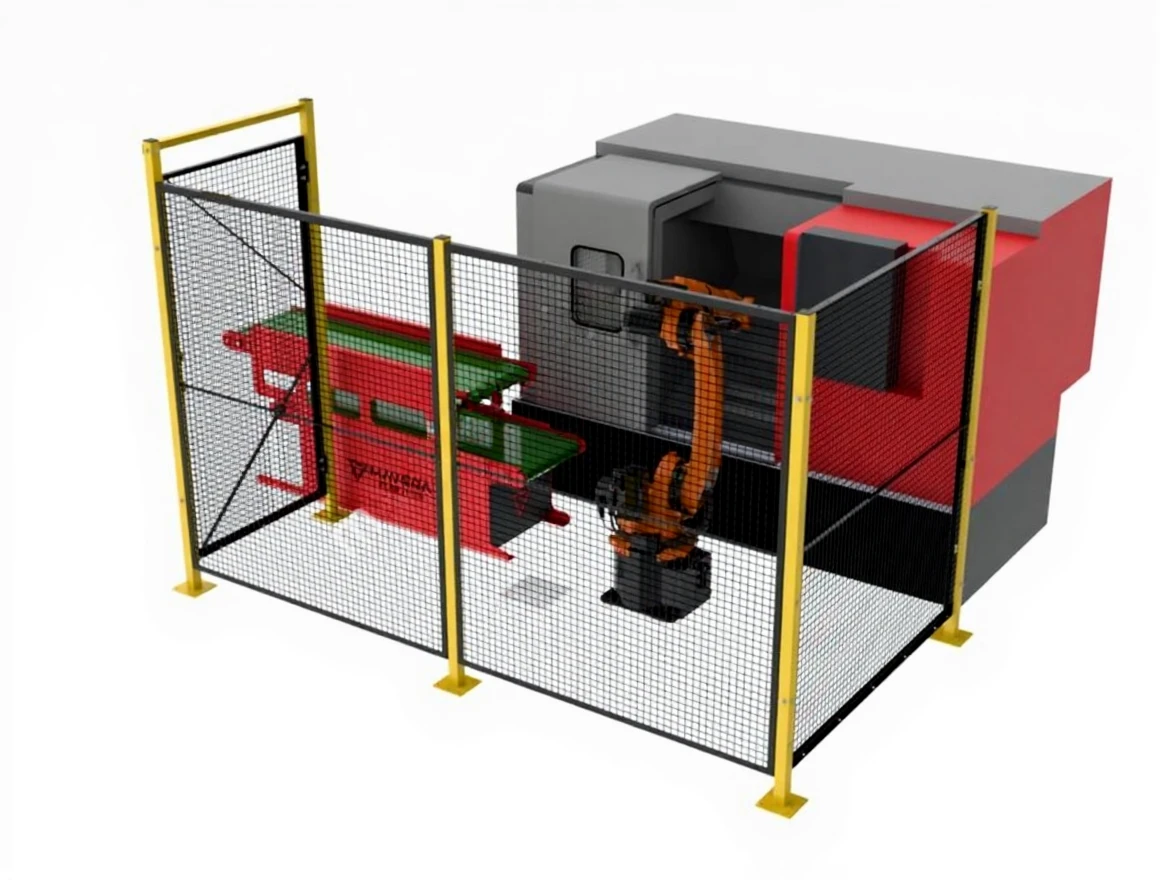

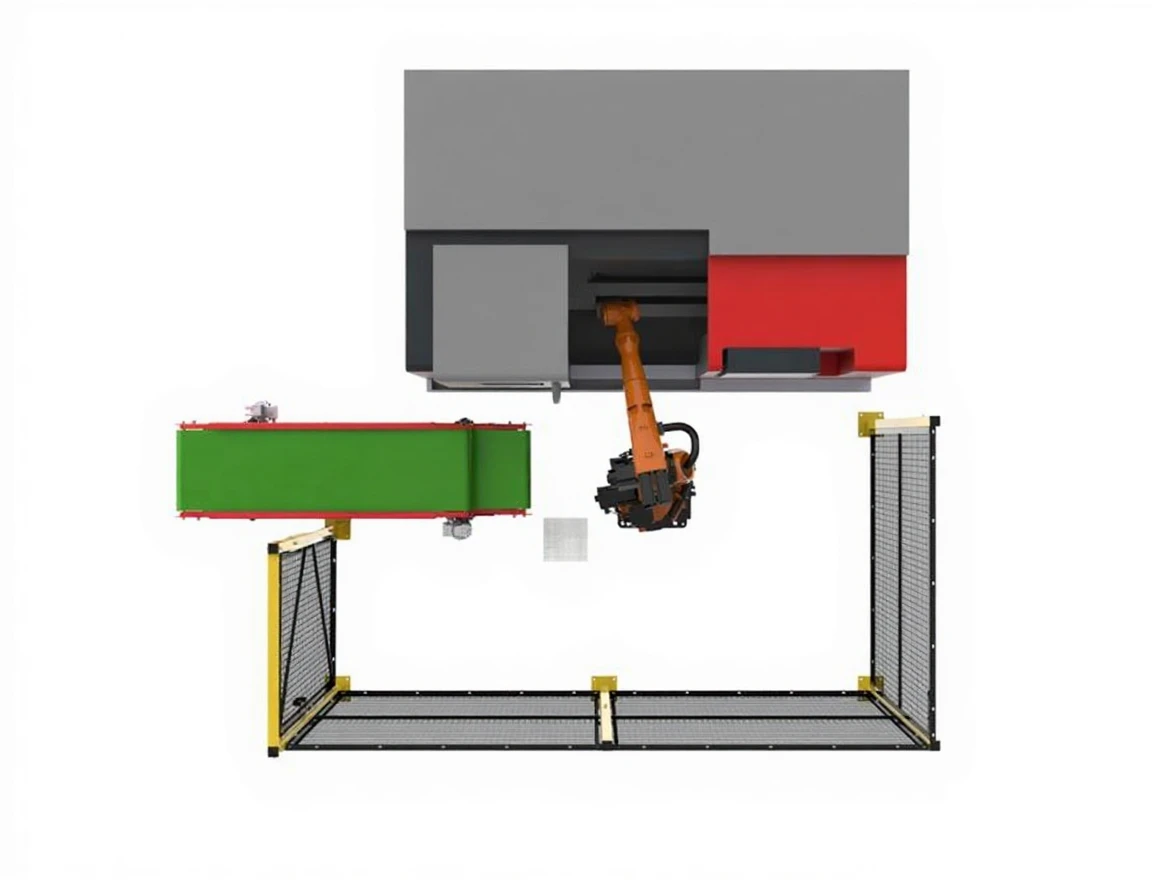

MVR-BELT (Conveyorized CNC Feeding Cell)

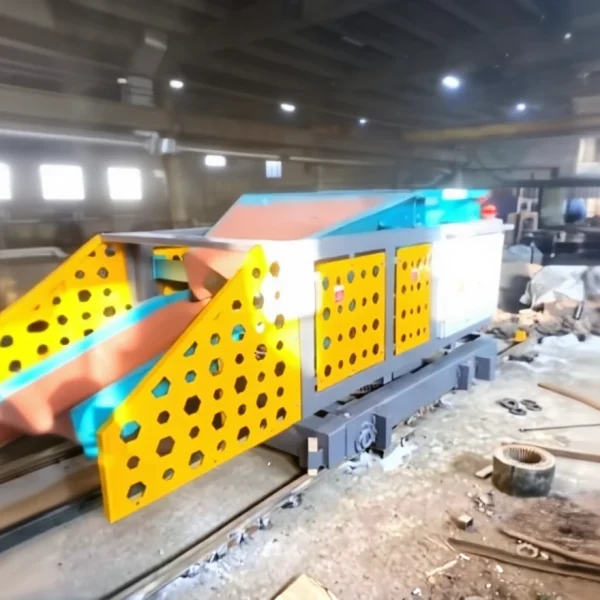

MVR-Belt is a conveyorized CNC feeding system developed for mass production processes. Materials are arranged on the conveyor with alignment guides and brought to the robot’s access point, the robot then feeds the parts to the CNC machine automatically. Finished products are transferred to crates via unloading conveyor, and the production process continues seamlessly.

Key Features:

– Alignment Guides: Ensuring the parts on the conveyor are positioned regularly and accurately.

– Robot Feeding: The robot automatically transfers aligned parts to the CNC machine.

– Unloading Conveyor: Automatic unloading of processed products to crates.

– Multi-Product Stacking: More stacking of parts with the same geometry on the conveyor for quick and efficient feeding.

– Continuous Flow: Automatic and regular production from material input to product output.

Advantages:

– Maximum speed and efficiency in mass production lines.

– Cost advantage by minimizing operator intervention.

– Reliable production with high-precision alignment.

– Continuous material flow with input-output conveyors.

– Ideal solution for repetitive and high-volume productions.