Longitudinal Root Removal and Source Mouth Opening Machine

| Brand | Graebener |

|---|---|

| Model Type |

G-KA-002 |

Graebener Longitudinal Weld Seam Opening and Root Removal Machines

Preparing the weld seam properly means making high-quality welding. That’s why we developed the Graebener® Longitudinal Weld Seam Opening and Root Removal Machine. Utilizing our leading market experience on a global scale, you can prepare welding seams in milling depths of up to 165 mm more profitably, faster, and healthier than ever before.

Overview

Until the 1990s, we operated our own Graebener® pipe factory and prepared our pipe welding seams through boring and manual processes. Then we developed the Graebener® Weld Seam Opening and Root Removal Machine, which today more than 100 customers on four continents benefit from our market-leading machine technology.

Graebener® longitudinal weld seam opening and root removal machines enable the cost-effective, reliable, and safe preparation of longitudinal seams in pipes, ships, and various devices. Therefore, our weld seam opening and root removal machines have been popular machines used for milling even the narrowest weld seams for years. According to real usability studies, our machines provide over 50% cost advantage.

Your Graebener® machine will save you time and money. Benefit from our individual concepts and numerous advantages we offer compared to traditional chamfering or grinding methods.

Machine Concepts

Depending on the individual usage type, Graebener® long edge milling machines are produced in two different design concepts: below ground level and above ground level. With these two machine concepts, we offer you the most perfect solution for cost-effective weld seam preparation. As a machine manufacturer, we also develop personalized special machine designs on demand.

Graebener® Longitudinal Weld Seam Opening and Root Removal Machine, Underground Design, Type GLF

Graebener® Longitudinal Weld Seam Opening and Root Removal Machine, Above-ground Design, Type GLF-O

All Graebener® longitudinal weld seam opening and root removal machines are equipped with an intelligent copying system that equalizes the height difference on non-flat pipe supports. Thus, your Graebener® machine always provides a constant stitch depth.

Take advantage of the technical benefits of your Graebener® longitudinal weld seam opening and root removal machine:

-

Up to 1,000 mm per minute milling speed

-

Seam tracking feature on the control screen with integrated camera

-

Low-cost milling cutters with multiple cutting edges

-

State-of-the-art Graebener® turning device ensures positioning of cones and cylinders up to 15 meters in diameter for welding seams independently of a crane

Milling and Slotting

Compared to standard processes such as carburization or grinding for root removal, the Graebener® milling method provides numerous advantages for weld seam opening and root removal:

-

Improved seam quality

-

Enhanced working conditions

-

Recyclable chips

-

Reduced processing time

-

Prerequisite for an automatic welding process

-

Reduced welding seam errors

-

Visual inspection possibility of inside weld root

-

Reduction of welding slag and consequently heat input

-

Reduction of energy consumption

As proven by real studies with our customers, as a machine operator, you can save time and money. Furthermore, you can protect the health of your machine operators and significantly increase the quality of weld preparation.

Related products

AFM 1270X1.5 Sliding Piece Molded Manual Lever Top-Bottom Straight Blade Guillotine Shear Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

AFM 1270×1,5 |

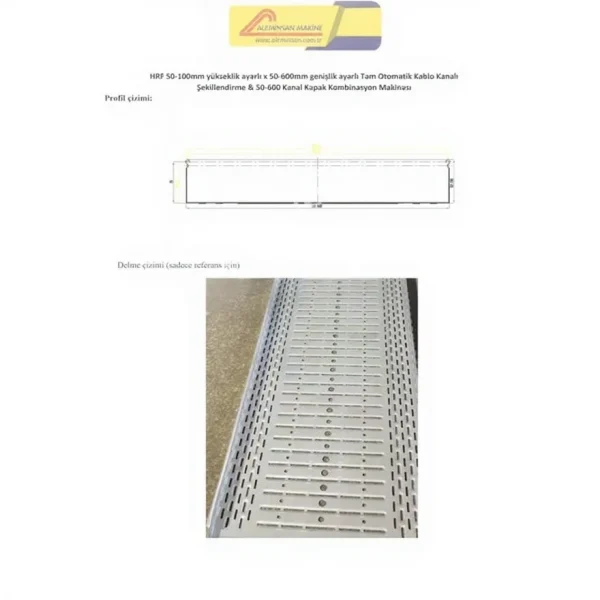

Cable Duct Forming Machine

In stock

| Brand | Aleminsan |

|---|---|

| Model Type |

HRF 50-100mm yükseklik ayarlı x 50-600mm |

IR1270X75X1,5 (3-Pack) Motorized and Manual Roller Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

IR 1270X75x1,5 |

RS 1270X90 2,5 (3 Piece) Manual Cylinder Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

RS 1270×90 |

RST-M 1270X86X2,5 (3-Piece) Motorized Reinforced Roller Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

RST-M 1270x86x2,5 |