100-15000 Kg Single Column Exterior Elevator

| Brand | Albay Lift |

|---|---|

| Model Type |

100KG |

Albay Lift

100-15000 Kg Single Column Exterior Elevator

The hydraulic load platforms manufactured by Albay Lift Elevator have been successfully approved by the tests of TSE, MMO, and IQNORM companies. The platform, which has successfully passed periodic maintenance tests, will continue to serve for a long time.

These elevators are produced for the purpose of carrying loads. Comfort and speed are not sought compared to passenger elevators. This freight elevator is typically used for transporting materials or pallets between the floors of buildings.

It can be easily used in places where heavy load transportation is intense, such as buildings, warehouses, factories, shopping malls, etc., or anywhere you need.

It provides efficient, comfortable, and safe access to mezzanines, basements, or any level of a multi-story building.

We manufacture custom Single Column Exterior Freight Elevators according to the desired dimensions based on the user’s needs and requests.

Freight elevators are designed to carry more than 100 Kg or 15000 Kg.

Single Column, Double Column, and Four Column drive systems are regularly manufactured.

Freight elevators are used under the heaviest conditions.

As with passenger elevators, optional features can also be selected for freight elevators.

Regardless of the travel distance, with our freight elevator solutions, you can experience a comfortable ride and achieve significant savings in terms of operating costs.

Our door types can be used as collision doors, semi-automatic doors, double-wing doors, automatic doors, or sliding doors, providing the desired clear opening and height according to the needs.

Hydraulic Cylinder and Chain

The lifting operation is performed by elevators that use a pump driven by electricity to send hydraulic fluid to a lifter that directly or indirectly affects the cabin. In these elevators, downward movement occurs due to the weight of the cabin itself.

In hydraulic elevators, the motor is generally located at the first stop level. Here, there is an oil tank and above it, a hydraulic machine (device), control panel, and hoses through which hydraulic fluid passes. Hydraulic elevators operate based on the principle of the pump, driven by electricity, pushing oil to lift the platform with pistons. The pumped oil moves the cylinder through a pipe by fulfilling certain conditions from the hydraulic machine. The cylinder is directly or indirectly connected to the platform. The platform pushed by the cylinder is moved to the required floor with the received command.

For protection against falling in load platforms, we use locking mechanism, high precision, wear-resistant Ø100mm hydraulic cylinders and Ø70mm shafts. The 12B chain model used has a smooth surface, compact structure, standard chain teeth, high load capacity, and pulling resistance. It is also quite easy to clean and maintain.

Limit Switch (Movement Switch)

One of the important components of the load platform is the limit switches. The limit switch is a special model of double-directional roller L5K13MEP-123 with IP65 class. It is used to convert mechanical displacement into an electrical signal. It ensures the height of the elevator is limited with high precision.

Safety

The overflow valve prevents high pressure when the hydraulic platform is lifted.

The manual emergency valve allows descent to the nearest floor in case of an emergency such as a power outage, earthquake, etc.

The hose burst valve cuts off the oil channel to prevent the load from falling off the platform when the hose bursts in the hydraulic system.

Low Cost

With an advanced and safe hydraulic system and control mode, there is a low failure rate.

Related products

Construction Hoist, Material Hoist, Industrial Elevators

In stock

| Brand | Maksanlift |

|---|---|

| Model Type |

Mks Acrobat 2000M |

Single Column 1 Ton 8 Meter Cruise Hydraulic Cargo Elevator

In stock

| Brand | Olslift |

|---|---|

| Model Type |

O-YA009 |

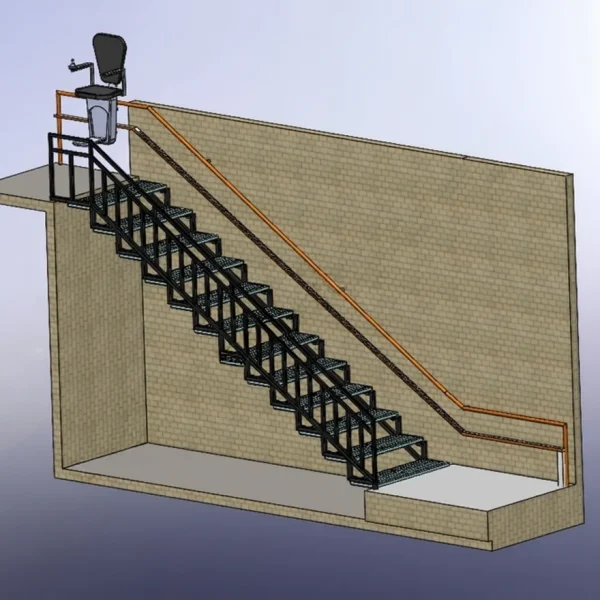

Stairlift Wheelchair Lift for Disabled with Stairs Climbing Chair

In stock

| Brand | Expert Lifting |

|---|---|

| Model Type |

EML-200 |