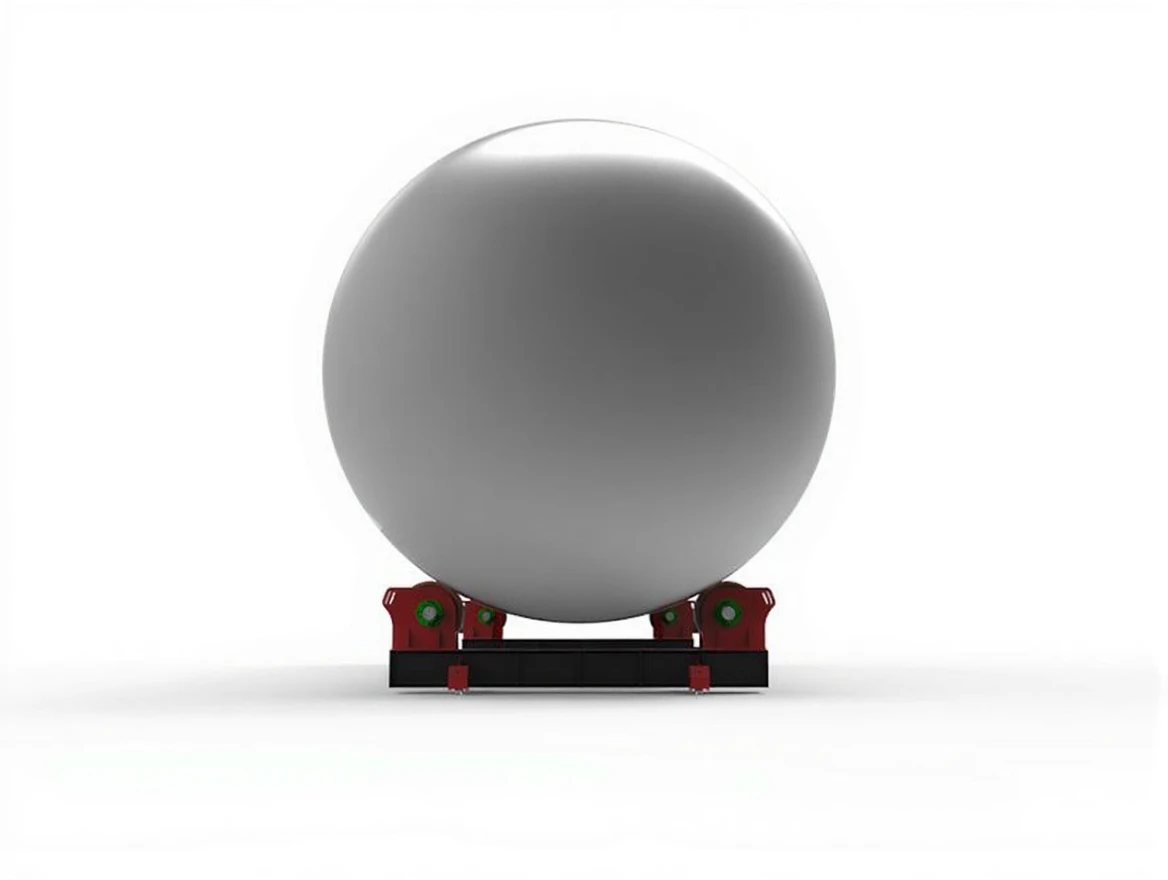

100 Ton Conventional Rotating System

YKS BSRROT 090-100

Rotators are used to facilitate production in all industries around the world and for easy assembly of tanks, barrels, pressurized and cylindrical containers of all types and sizes. Rotators are designed to improve the speed and efficiency in both automatic and manual welding, with increased productivity and minimized use of extra processing methods and crane. Rotators allow operators to control all functions which include clockwise and counterclockwise rotation and rotate at extremely smooth, precise speeds. As of now, it responds to rotators with capacities ranging from 5 to 150 tons. It has the capacity to manufacture up to 250 tons upon request.

Standard Features

• PU Coating

• Bolted diameter adjustment

• Adjustable rotation speed

• 5-meter wired remote control

• Digital speed display on the control panel for rotation tracking

• AC motor

• Support group to prevent the axial movement of the piece

Optional Features

• Special wheel designs for areas requiring high heat

• Motorized wheel axis distance (diameter) adjustment

• Manual wheel axis distance (diameter) adjustment

• Motorized walking system (Driver-motorized, Idler-manual)

• Chassis – Brush Group

• Synchronous operation capability with column boom systems

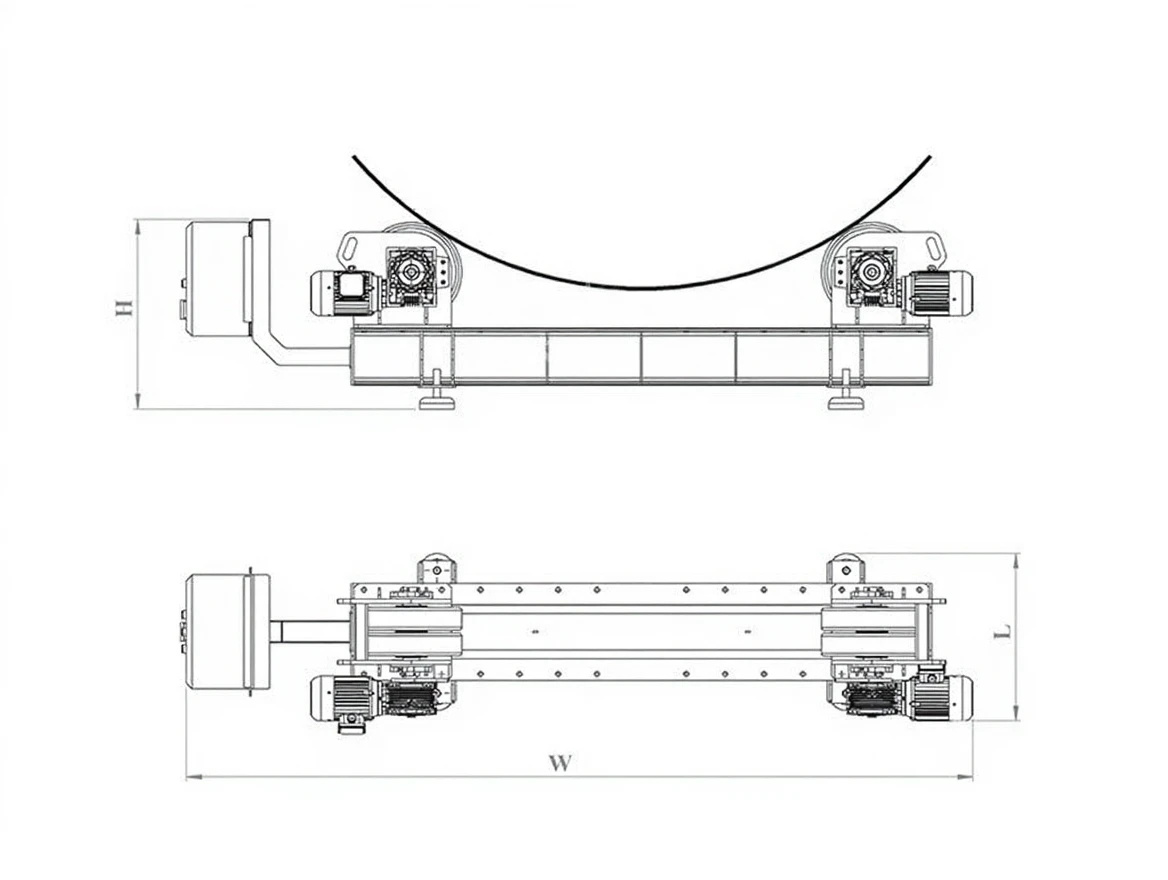

Technical Specifications of YKS BSRROT 090-100

| TECHNICAL SPECIFICATIONS | BSRROT 005 | BSRROT 010 | BSRROT 020 | BSRROT 030-040 | BSRROT 050-060 | BSRROT 070-080 | BSRROT 090-100 |

| Turning Capacity (ton) | 5 | 10 | 20 | 40 | 60 | 80 | 100 |

| Unit Carrying Capacity (ton) | 2.5 | 5 | 10 | 20 | 30 | 40 | 50 |

| Min. Rotation Diameter (mm) | 250 | 250 | 520 | 520 | 520 | 520 | 520 |

| Max. Rotation Diameter (mm) | 3700 | 3700 | 4500 | 6000 | 6000 | 6000 | 6000 |

| Wheel Diameter (mm) | 300 | 300 | 350 | 350 | 350 | 550 | 550 |

| Wheel Width (mm) | 70×2 | 70×2 | 160 | 160 | 150 | 150×2 | 160×2 |

| Wheel Material(mm) | Polyurethane | Polyurethane | Polyurethane | Polyurethane | Polyurethane | Polyurethane | Polyurethane |

Related products

Ø160mm 4 Metre Acrobat Arm and Mounting Bracket Welding Fume Extractor Arm

In stock

| Brand | ProfAir |

|---|---|

| Model Type |

F40T |

40 Ton Capacity Rotator Rotator Tank Welding Machine

In stock

| Brand | Temel Makina |

|---|---|

| Model Type |

TMLKTRÇS 40T |