Description

1000 Litre / Hour Egg Pasteurizer

Purpose and Capacity:

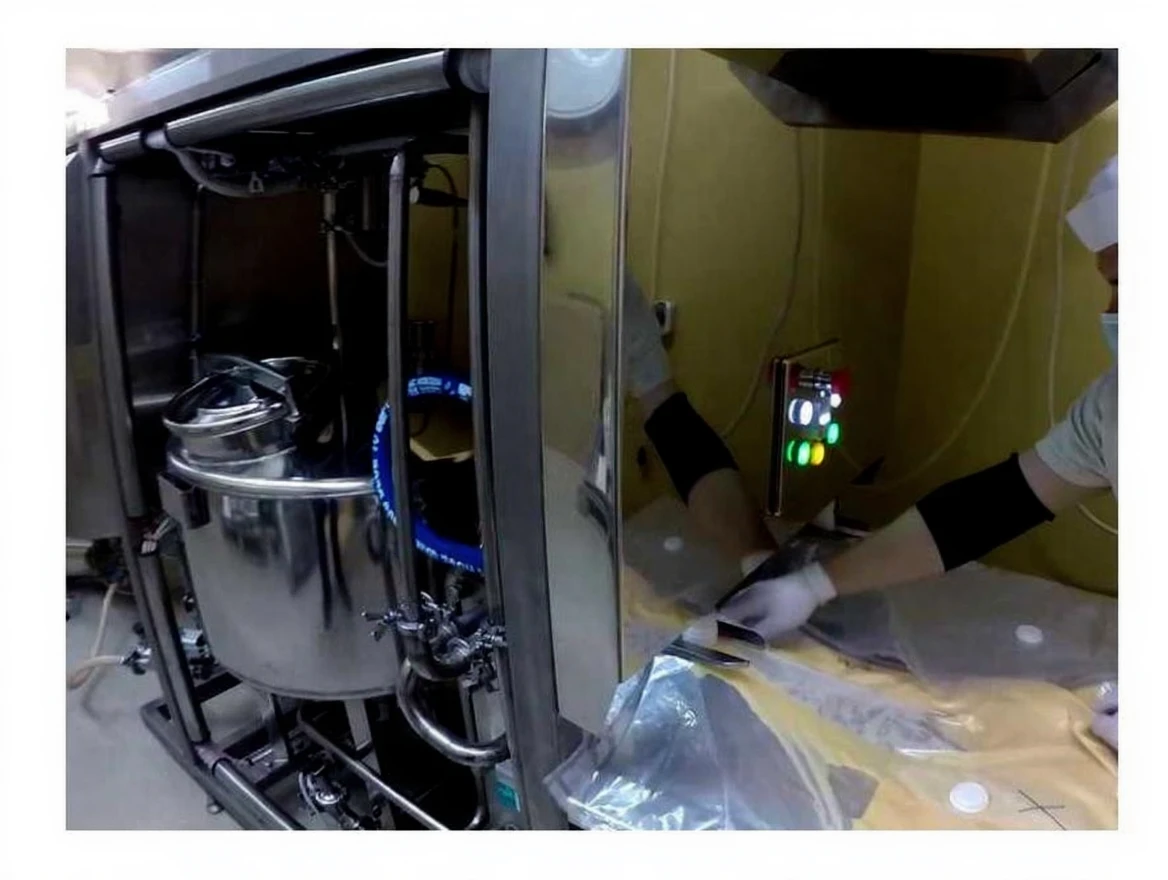

The Egg Pasteurizer is designed for pasteurizing liquid egg products (egg whites, egg yolks, whole eggs). It has a pasteurization capacity of 1000 liters per hour.

Pasteurization Process:

- The process is initiated by the machine operator using the control panel.

- Egg products are transferred from the storage tanks to the pasteurization system's balance tank using a transfer pump.

- The pump is controlled by automatic level controls in the balance tank.

- The product is then sent to the heat exchanger’s regeneration section using a positive discharge pump.

- Here, the temperature of the liquid egg is raised to approximately 50°C – 55°C.

- After the regeneration section, the product is homogenized and reaches the rotary coil heater where its temperature is increased to 67°C.

- The product enters the holding tubes and is held for 3 minutes before being cooled.

- In the cooling section, the product is cooled to 2-4°C and then packaged or sent to storage.

Advantages:

- Does not require a separate boiler for hot water.

- No need to purchase a homogenizer.

- Provides precise temperature control.

- Minimal installation time required.

- Suitable for the production of high-quality egg products.

- Easy filling with integrated filling unit.

- Compact design allows it to fit into small spaces.

- Can pasteurize at high temperatures for extended periods without requiring frequent cleaning.

-

İşte 1000 Litre / Saat Yumurta Pastörizatörü hakkında İngilizce, Almanca, Rusça ve Fransızca çeviriler:

İngilizce:

1000 Litre / Hour Egg Pasteurizer

Purpose and Capacity:

The Egg Pasteurizer is designed for pasteurizing liquid egg products (egg whites, egg yolks, whole eggs). It has a pasteurization capacity of 1000 liters per hour.Pasteurization Process:

- The process is initiated by the machine operator using the control panel.

- Egg products are transferred from the storage tanks to the pasteurization system's balance tank using a transfer pump.

- The pump is controlled by automatic level controls in the balance tank.

- The product is then sent to the heat exchanger’s regeneration section using a positive discharge pump.

- Here, the temperature of the liquid egg is raised to approximately 50°C – 55°C.

- After the regeneration section, the product is homogenized and reaches the rotary coil heater where its temperature is increased to 67°C.

- The product enters the holding tubes and is held for 3 minutes before being cooled.

- In the cooling section, the product is cooled to 2-4°C and then packaged or sent to storage.

-

Advantages:

- Does not require a separate boiler for hot water.

- No need to purchase a homogenizer.

- Provides precise temperature control.

- Minimal installation time required.

- Suitable for the production of high-quality egg products.

- Easy filling with integrated filling unit.

- Compact design allows it to fit into small spaces.

- Can pasteurize at high temperatures for extended periods without requiring frequent cleaning.

-

Technical Specifications (PS 1000):

- Electrical Specifications: 15 kW

- Capacity: 1000 Liters

- Air Pressure: 6 Bar – 30 Nm²/h

- Inlet Temperature: 14°C

- Pasteurization Temperature: 63-67°C

- Outlet Temperature: 2-4°C

- Holding Time: 3 minutes