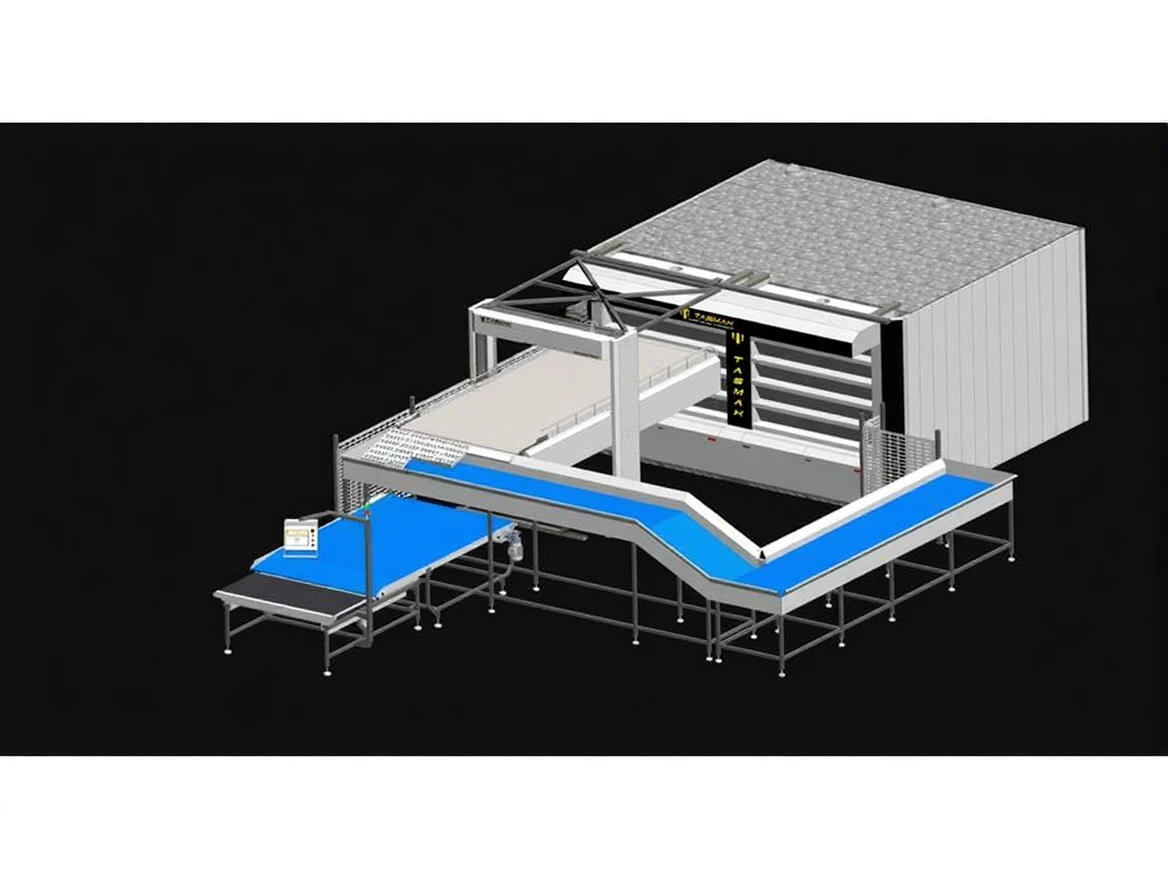

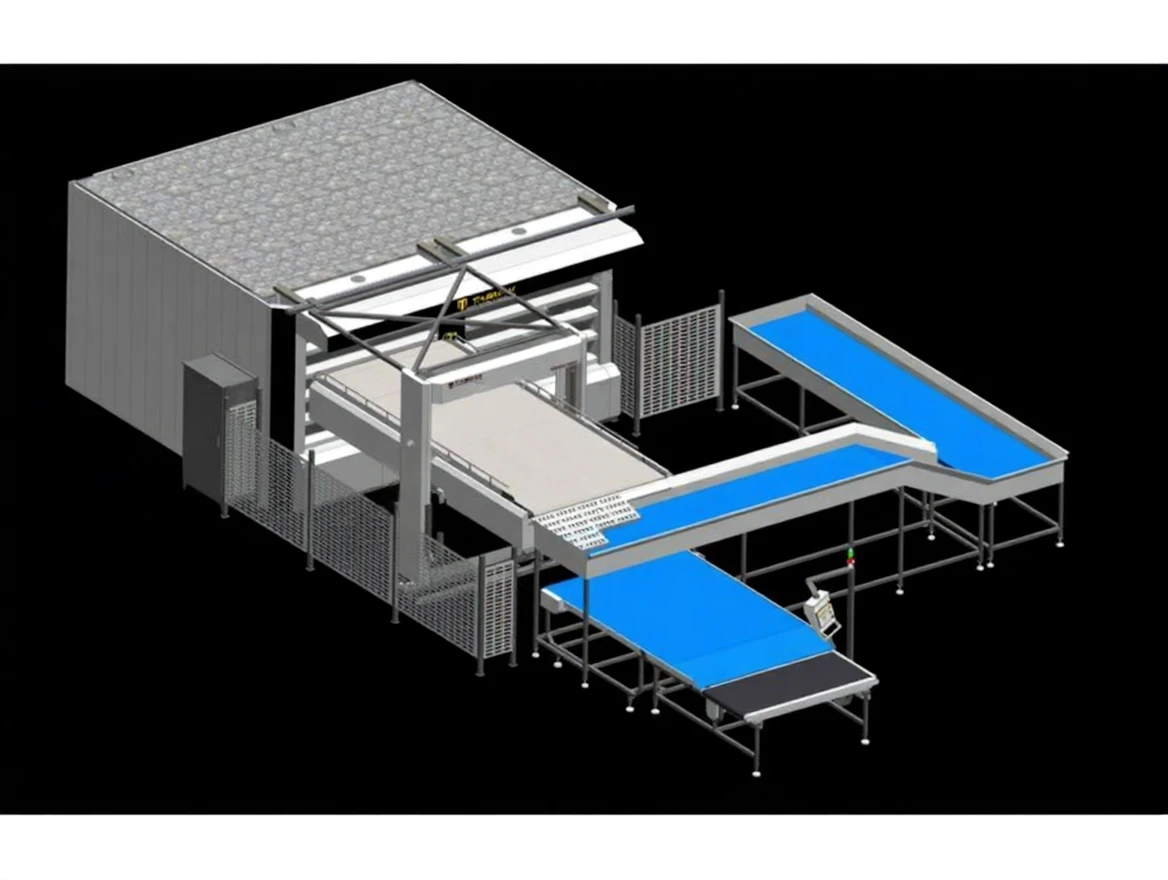

1200 Pieces / Hour Stone Based Tubular Oven and Robot Automation System

| Brand | Taşmak Makina |

|---|---|

| Model Type |

TF1800-5K-1200 |

1200 Pieces / Hour Stone Based Tubular Oven and Robot Automation System

Taşmak Makina’s TF1800-5K-1200 model is a highly efficient production system equipped with stone-bottom tube furnace technology. Designed for professional producers in the bakery industry, this system has an hourly production capacity of 1200 pieces of 200 grams of bread and guarantees efficient and uninterrupted production processes. This oven system, produced with the latest technology, prioritizes not only high capacity production but also excellent baking quality.

The 5-layer pipe oven system, which is one of the basic components of the system, uses a stone-based structure in each layer to provide high performance cooking. These stone bases ensure that the heat is distributed evenly, ensuring that the outer surfaces of the breads are crispy and the inner parts are soft. The use of double ovens allows different products to be baked at the same time and makes the production line more efficient. Tube oven technology ensures that breads are baked at the optimal temperature, thus maintaining quality.

The automatic shovel system in the system loads the dough into the oven quickly and precisely. The shoveling process is completely automatic and ensures that the breads are placed properly in the oven without requiring operator intervention. The precise working principle of the shoveling system helps ensure consistent product quality and eliminates human errors in the production process.

The dough loading machine transports the bread dough properly to the oven. This machine allows the dough to be transported at the desired speed and in the right amount, thus supporting the fluidity and efficiency of the production process. During the loading process, the dough maintains its shape and ensures proper placement in the oven.

After the baking process of the bread is completed, the bread unloading conveyor system is activated. This system unloads baked bread safely and efficiently and directs it to the correct area. The conveyor system ensures that the bread is transported without damage and increases the efficiency of the production line. Breads are transferred from the production area to the packaging area without any problems.

All these processes are managed by the dashboard and automation system. The panel system operates the oven, shoveling and dough loading machines and conveyor systems synchronously. This central control system allows monitoring of every stage in the production process and allows rapid intervention against possible malfunctions. Thanks to its user-friendly interface, operators can easily control and optimize the system.

Security has an important place in this system. 2 safety barriers are designed to ensure the safety of operators. In an environment where oven and automation systems operate at high speed, these barriers prevent possible accidents and guarantee the safety of operators.

The system also attracts attention with its mat board size. The 70×85 mm sized baking board ensures that the temperature and humidity levels inside the oven are maintained ideally and helps the breads to bake in the best possible way. The baking board optimizes the air flow in the oven, making the cooking process perfect.

Taşmak Makina TF1800-5K-1200 is the perfect solution for large-scale bakeries and food production facilities with its high production capacity, efficient automation systems and safety measures. This system reduces labor costs, increases production speed and ensures high quality at every stage. It provides an uninterrupted, fast and safe bread production process in high-capacity production facilities.