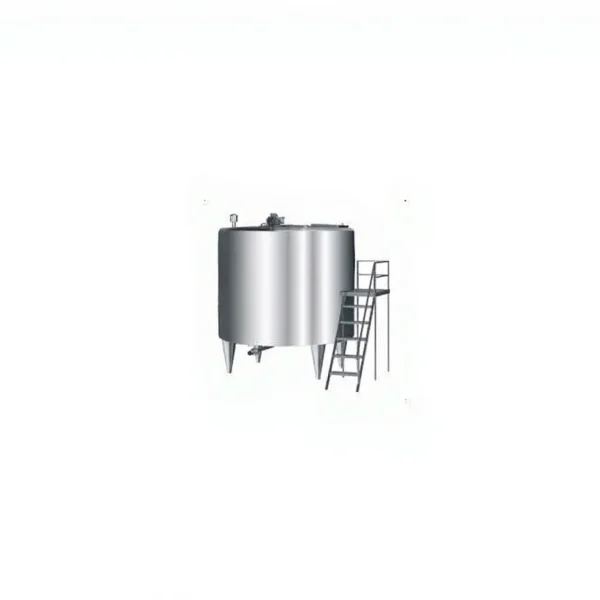

2000 Lt Paslanmaz Lor Peyniri Kaynatma Kazanı

| Brand | Orçan Makina |

|---|---|

| Model Type |

O-LK-001 |

2000 Lt Stainless Whey Cheese Boiling Vat

It is a device that allows the whey, which emerges during the production of hard and semi-hard cheeses, to be boiled and converted into whey cheese. With its steam-heated design, hygienic stainless steel body, and efficient straining system, it aims to recover valuable proteins in the whey to the maximum level.

Operation Principle & Technical Specifications

-

Heating and Boiling of Whey

-

The whey is heated to high temperatures by the steam supplied to the tank wall in a controlled manner.

-

During this process, proteins such as albumin and globulin precipitate and separate from the liquid.

-

-

Straining & Whey Cheese Production Process

-

After the boiling process is completed, the resulting curd is transferred to straining/pressing tanks to be completely separated from the liquid phase.

-

This process allows the whey cheese to have a better consistency and the moisture level to be at the ideal level.

-

Tank Design & Technical Specifications

AISI 304 Stainless Steel Body – The tank's interior and exterior surfaces are made entirely of hygienic stainless steel.

High-Temperature Resistant Insulation – Thermal insulation with stone wool minimizes heat loss to the environment, ensuring energy efficiency.

CIP (Clean-in-Place) System – The tank's interior surface is easily cleaned by CIP washing balls integrated into the upper part.

Operator Platform & Stairs – Stainless steel non-slip operator platform is available for capacities of 2000 litres and above.

High Tank Legs – Raised from the ground with 4 legs, allowing easy movement of the whey pressing tank.

Advantages

Protein Recovery – The whey boiling process recovers valuable proteins in the whey, reducing waste and creating an additional source of income.

Hygienic & Durable Structure – The use of entirely stainless steel materials ensures food safety and long-lasting use.

Energy-Efficient Heating – Controlled heating with steam ensures maximum efficiency with minimum energy consumption.

Easy Cleaning & Maintenance – CIP system integrated washing balls provide quick cleaning that complies with hygiene standards.

Industrial Usage Areas

-

Milk and cheese production facilities

-

Whey cheese production plants

-

Industrial milk by-product processing systems

The whey boiling vat is an indispensable equipment for cheese producers with its hygienic and efficient working principle.