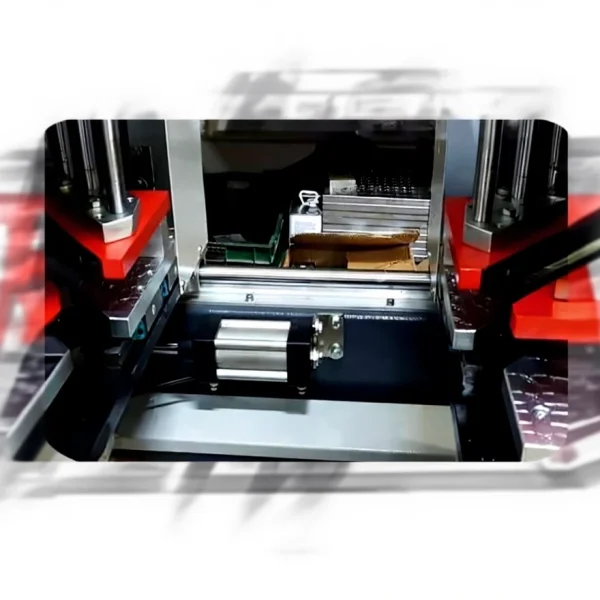

210x280x15 cm Professional Aluminum CNC Machining Machine

| Brand | Drachen |

|---|---|

| Model Type |

2128 Hyper |

210x280x15 cm Professional Aluminum CNC Machining Machine

CNC Router Machine Features

-

Computer-Controlled Operation

-

Automatic Processing: Works seamlessly with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software for integrated design and production.

-

Precision: Minimizes human error and performs operations with millimeter accuracy.

-

-

Versatile Usage

-

Cutting and Shaping: Precisely cuts wood panels and shapes them into various geometries.

-

Carving and Engraving: Ideal for decorative patterns and text.

-

Drilling and Channeling: Creates holes and channels for wood assembly operations.

-

-

High Speed and Efficiency

-

Fast Processing Times: Increases production capacity.

-

Multi-Operation Capability: Performs multiple tasks with a single software.

-

-

Durable and Robust Construction

-

Stable Table: Reduces vibration, ensuring precise cutting.

-

Sturdy Materials: Made with durable components suitable for industrial production.

-

-

Ease of Use and Programming

-

User-friendly interface for easy control by operators.

-

Advanced software support makes it easy to implement complex designs.

-

-

Eco-Friendly Solutions

-

Operates with dust extraction systems, keeping the environment and work area clean.

-

Provides sustainable solutions with low energy consumption.

-

Technical Specifications

-

Net Working Area: 210x280x15 cm

-

Industrial Control System

(Remembers its position during power outages and resumes work) -

Wired Handwheel: Allows precise and remote control of the machine

-

X-Axis: 1.5 kW Servo Motor

-

Y-Axis: 1.5 kW Servo Motor

-

Z-Axis: 1 kW Braked Servo Motor

-

All Axes: 3 Archmin 120 body reducers with a 1/7 ratio

-

Tool Change: 12 units under the bridge

-

Linear Motion System: All axes are precision 25mm

-

Gear and Pinion: Ground German GAMBINI brand

-

Spindle Motor: Imported 9kW, 24,000 rpm, ceramic bearing

-

Vacuum Motor: 7.5 kW blower, 530m

-

Vacuum Table: Operates regionally, electronically, and automatically

-

Table: Compact material

-

Motor Tool Reset Probe

-

Automatic Tool Lubrication System

-

Manual Lubrication Press for all axes

-

Industrial Design Emergency Stop Button

-

Industrial Design Electrical Panel

Related products

400 mm Conveyor PVC and Aluminum Profile Bottom Cutting Machine

In stock

| Brand | Baertec |

|---|---|

| Model Type |

2AC400 |

Triple Springle Pvc Gripslot Drilling And Drain Slot Machine

In stock

| Brand | Turbomax |

|---|---|

| Model Type |

TRB16 |