350-750 kg/hour Nut Roasting Oven

| Brand | Seintro |

|---|---|

| Model Type |

SF 5000 |

350-750 kg/hour Nut Roasting Oven

Seintro SF 5000 is a conveyor-type convection roasting oven designed for nut producers and food processing facilities. With a capacity range of 350-1000 kg/hour, this model is perfect for roasting or drying various nuts such as hazelnuts, almonds, sunflower seeds, pumpkin seeds, peanuts, pistachios, and cashews, as well as spices, herbs, fruits, and vegetables at the desired temperature and time. The SF 5000 is ideal for medium-scale production plants, offering high efficiency and low energy consumption.

The oven is equipped with a system that applies air at the desired temperature through fans to the product as it moves along the conveyor belt, operating based on internal humidity control principles. This ensures homogeneous roasting for all types of products, and the quality of the roasted products can be consistently maintained at a high level. The independent multi-chamber design allows for processing different products simultaneously, with temperature and air circulation settings adjustable for each chamber, meeting different roasting needs.

Constructed with AISI 304 stainless steel chassis and wire mesh belt, the device maintains high hygiene standards and durability. The stainless steel structure enhances the oven's resistance to corrosive elements and simplifies cleaning and maintenance tasks. Additionally, exhaust gases generated by the burners are expelled outside without contacting the product, ensuring a healthy production environment. This helps preserve the natural aroma and flavor of the products.

The conveyor-based structure of the SF 5000 ensures that products progress smoothly to the cooling chamber, providing continuous efficiency in the production process. This continuous production capability ensures high capacity and uninterrupted output. Parameters such as chamber temperatures, conveyor speeds, and product thicknesses can be easily adjusted via the touchscreen control panel (HMI panel), allowing for customized roasting processes. Automatic product thickness adjustment further enhances precision, resulting in the ideal color and aroma.

The Seintro SF 5000 is designed with energy efficiency in mind, featuring a high-efficiency thermoblock system. The insulation minimizes energy loss, helping to lower operational costs. Proportional burners allow for precise temperature adjustments, preventing waste and reducing costs. The motor-driven belt brushing system and automatic belt cleaning system make maintenance and cleaning easier, ensuring operational continuity.

Safety is also a key consideration in the SF 5000. Features such as the fan failure detection system, chain-driven conveyor system, and lid safety sensor ensure safe and uninterrupted machine operation. Additionally, the conveyor safety system and alarm for open lids prevent product loss in case of conveyor stoppage. These safety measures contribute to the efficient and secure continuation of the production process.

The efficient design and ergonomic features of the SF 5000 make operation, maintenance, and cleaning faster and easier. The Seintro SF 5000 delivers high quality, efficiency, and safety for the nut and food processing industries. This oven ensures continuous production at high capacity, allowing businesses to operate efficiently.

|

Kapasite (kg/saat) |

SF-5000 |

|---|---|

|

İç Fındık |

700 |

|

Tuzlu İç Yer Fıstığı |

350 |

|

Kabuklu Yer Fıstığı |

200 |

|

İç Antep Fıstığı |

500 |

|

Kabuklu Antep Fıstığı |

350 |

|

Tuzlanmış Ay Çekirdeği |

250 |

|

Kabak Çekirdeği |

300 |

|

Badem |

350 |

|

Kaju |

350 |

Boyutlar

|

Boyutlar (mm) |

SF-5000 |

|---|---|

|

Genişlik |

2400 |

|

Uzunluk |

5370 |

|

Yükseklik |

2400 |

Enerji Tüketimi

|

Enerji Tüketimi |

SF-5000 |

|---|---|

|

Enerji Tüketimi (kW) |

11 |

|

Yakıt Tüketimi (Doğalgaz – mn3h/kW) |

8/72 |

|

Yakıt Türleri |

|

Özellikler

|

Özellikler |

SF-5000 |

|---|---|

|

AISI 304 Kalite Paslanmaz Çelik Şase |

|

|

AISI 304 Kalite Tel Örgü Bant |

|

|

Her Kabinde Bağımsız Sıcaklık Kontrolü |

|

|

Fan Arıza Tespit Hava Presostatı |

|

|

Kavurma / Soğutma Kabin Sayısı |

2/1 |

|

Nem Egzoz Fanı |

|

|

Hijyenik Hava Filtresi |

0 |

|

Kabin İçi Aydınlatma ve Gözlem Camı |

0 |

|

Otomatik Ürün Kalınlığı Ayarı |

0 |

|

Kapak Emniyet Sensörü |

0 |

|

Dokunmatik Kontrol Paneli |

0 |

|

Operatör Paneli Standı |

0 |

|

Otomatik Bant Yıkama Sistemi |

0 |

|

Motor Tahrikli Bant Temizleme Fırçası |

0 |

|

Oransal Brülör ile Hassas Sıcaklık Ayarı |

0 |

|

Brülör Adetleri |

2 |

Related products

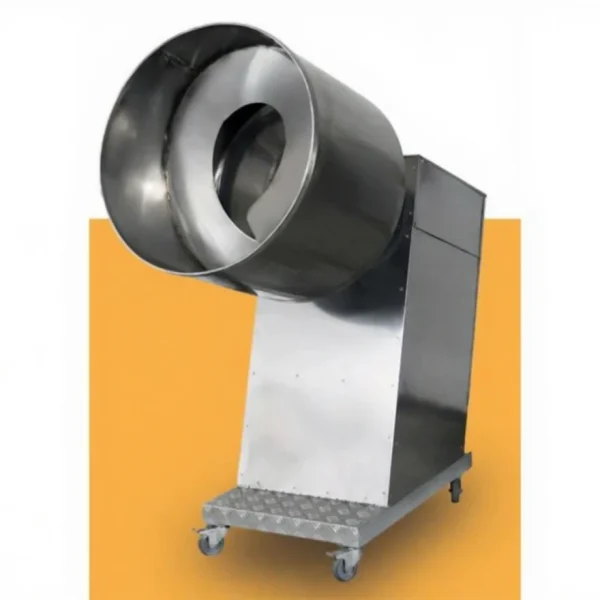

10 kg Yellow Roasted Chickpea Pumpkin Seed Sunflower Seed Peanut Coating Machine

In stock

| Brand | Alpnuts |

|---|---|

| Model Type |

BM 10 |

100 kg Yellow Chickpea Pumpkin Seed Sunflower Seed Pistachio Coating Machine

In stock

| Brand | Alpnuts |

|---|---|

| Model Type |

BM 100 |