NMT

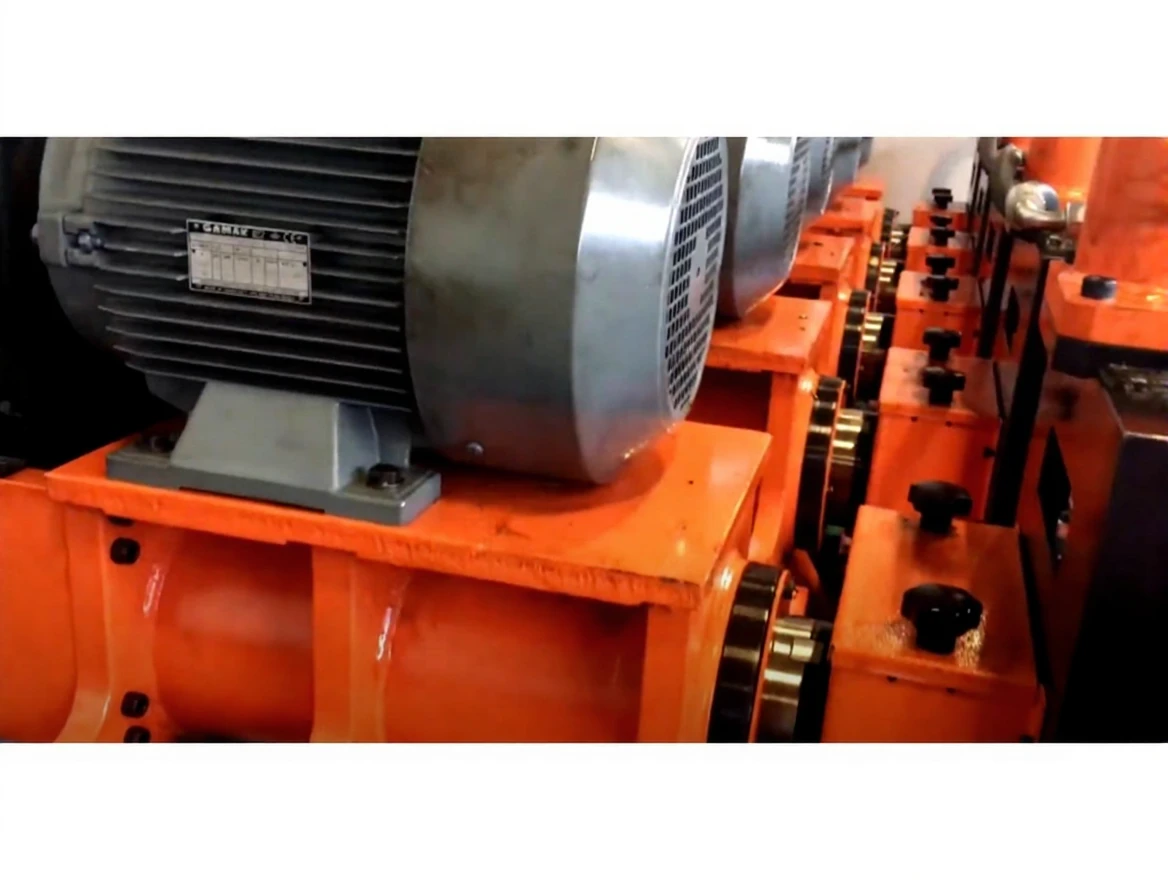

5 Head Automatic Chamfering Machine

General Information

What is an Automatic Chamfering Machine (5 Head)?

In machining, chamfering is the process of rounding off sharp corners.

The softened state of a 90-degree corner is achieved by cutting off the ear, resulting in a 45-degree chamfer.

It is a situation where a completely sharp corner is beveled. It eliminates burrs and sharp edges formed after cutting with a flat or circular optional chamfering process. In trifon, it ensures easy centering during the laying of the bolt on the railway by softening the burrs left after the trimming process.

Technical Information

Control System

-

PLC HMI

User Interface

-

Touch Panel

Production Capacity

-

900 Pieces / Hour

Chamfer Diameter

-

8 MM

Safety System

-

Emergency Stop

Installed Power

-

42.5 KW

Drive System

-

Phase Soft Starter Drive

Motor Drive Transmission

-

Belt System

Operating Voltage

-

380 V 3L-N-PE 50 HZ

Air Pressure

-

6 Bar

Weight of the Machine

-

1200 kg

Dimensions of the Machine

-

4×2.5×1.7 Mt

Advantages of the Automatic Chamfering Machine

Our automatic chamfering machine is manufactured with 5 heads. This way, you produce 5 trifons instead of 1 in the same cycle time. Thus, your manufacturing capacity increases by 400%. In terms of labor savings, it allows you to produce the same number of products with 1 operator instead of 5 operators. It has a powerful electro-hydraulic structure. A helical system has been preferred as the chip removal mechanism. This way, we ensure that the metal chips formed after cutting are automatically expelled from a single point outside the system. Since the entire system is operated by control, in case of any error, the detection and resolution time of the error is minimized from the fault page. It allows you to chamfer 15-20 workpieces per minute.

Prices of the Automatic Chamfering Machine

Currently, the prices of chamfering machines are not as high as expected. Especially when considering its functionality and features, this situation becomes clearer. Our machine operates with Siemens brand PLC, which is German-made. Siemens brand is also used as the touch screen. The mechanics are processed with precise tolerances in CNC. Considering these nuances, it is a machine with a good price-performance ratio. A 1-year warranty and operator training process is standard for all our machines.