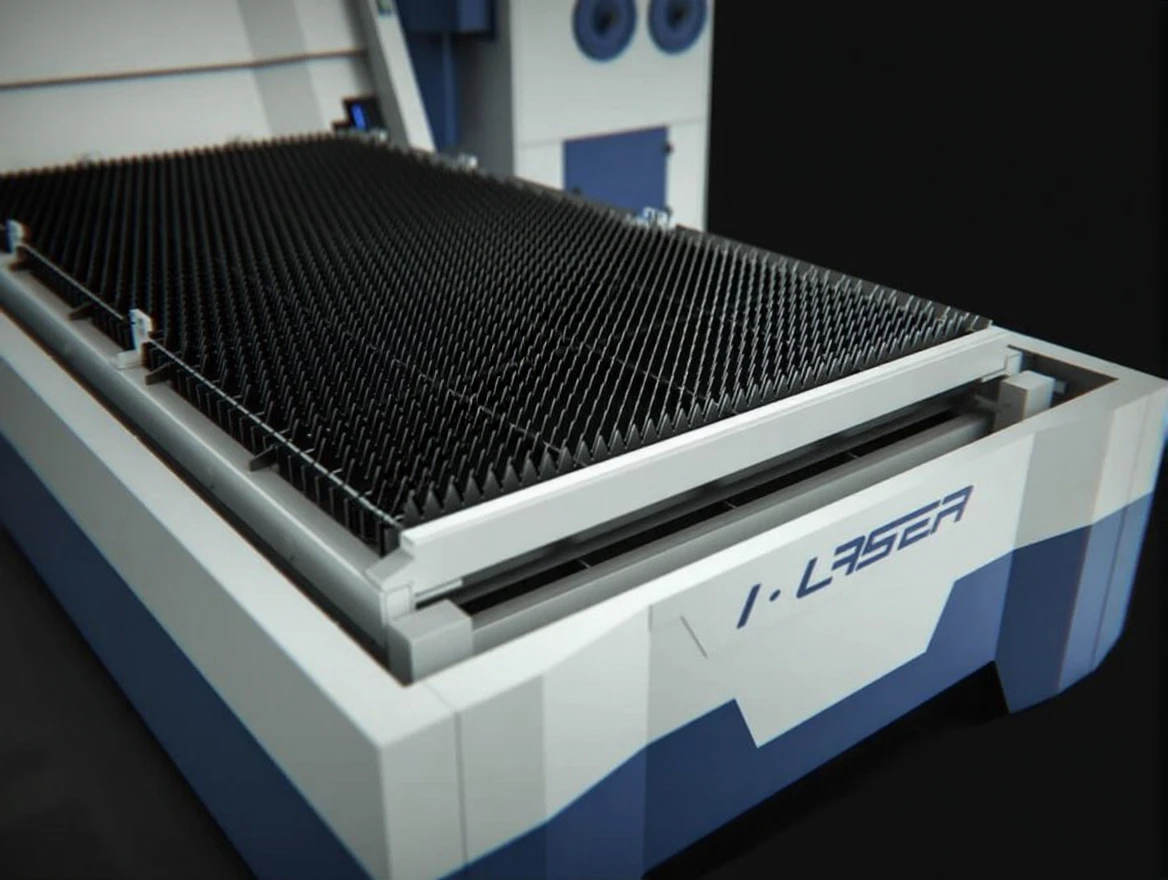

6000×2000 mm Fiber Laser Sheet Cutting Machine

| Brand | Cronosstech |

|---|---|

| Model Type |

FB 2060 |

FB 2060 – Fiber Laser Sheet Cutting Machine (OEM | Made in Turkey)

Working Area: 6000 × 2000 mm (6020 Model)

Short Product Description

FB 2060 Fiber Laser Sheet Cutting Machine; is an OEM production solution developed for precise, fast, and repeatable sheet cutting applications with its high rigidity steel construction, advanced CNC control infrastructure, and powerful fiber laser technology. It is suitable for heavy industry, metal processing, and mass production lines.

Key Advantages

-

OEM production – Made in Turkey

-

High speed, high acceleration, and precise positioning

-

Maximum operator safety with fully enclosed cabin

-

Optimized cutting modes for thin and thick sheets

-

Structure suitable for automation and mass production

-

Wide range of laser power options

Standard Features

-

CNC controlled fiber laser sheet cutting machine

-

Analyzed, high rigidity heavy-duty steel body and bridge structure

-

Rack-pinion drive system

-

Automatic motorized focusing laser cutting head

-

Capacitive sensor automatic height control system

-

Automatic focus distance adjustment during cutting

-

High precision linear guides and servo motor system

-

Windows-based, touch CNC control unit

-

Multi-language supported, user-friendly CNC interface

-

EtherCAT communication infrastructure

-

Monitoring of temperature, pressure, protective glass, and back reflection at the cutting head

-

Camera-supported monitoring system inside and outside the machine

-

LED status and warning indicators

-

Transmission of fiber laser beam via fiber cable

(no optical mirror/lens loss) -

Automatic sheet recognition and alignment systems

-

Fly-Cut (continuous series cutting) feature

-

No Piercing (non-blasting cutting) mode for thin sheets

-

Controlled blasting cutting mode for thick sheets

-

Fully enclosed cabin compliant with CE standards

-

Special safety glasses that do not transmit laser light

-

CNC controlled filtered ventilation system

-

Automatic nozzle cleaning and cutting head calibration

-

Conveyor slag and part discharge system

-

Moving table system

-

Emergency stop buttons and safety locks

Optional Features

-

Double pallet automatic table exchange system

-

Fiber laser resonator in different power options

-

Automatic sheet loading system

-

Automatic part unloading system

-

Advanced CNC controlled filter unit

-

Camera-based automatic sheet recognition and nesting software

-

Remote monitoring and reporting package

-

Oil cooler / climate control system

-

Additional LED lighting inside the cabin

-

Special cutting head alternatives

-

Additional gas control and pressure regulation systems

Technical Specifications – 6020 Model

Axes

-

X Axis: 6030 mm

-

Y Axis: 2030 mm

-

Z Axis: 120 mm

Movement Performance

-

Acceleration: 2.5 G

-

Max. axis speed: 150 m/min

-

Synchronized speed: 210 m/min

-

Positioning accuracy: ±0.05 mm

-

Repeatability accuracy: ±0.03 mm

Table & Loading

-

Max. table loading capacity: 3000 kg

-

Table change time (optional): ~30 sec

Laser Power Options

-

3 kW / 4 kW / 6 kW / 8 kW / 10 kW / 12 kW

Cutting Capacities (Max.)

-

Black sheet: 20 – 35 mm (depends on laser power)

-

Stainless steel: 8 – 25 mm

-

Aluminum: 8 – 25 mm

Gas Pressures

-

Oxygen: 13 bar

-

Nitrogen: 25 bar

-

Air: 13 or 25 bar

General

-

Machine weight: ~26,000 kg

-

Average electricity consumption: 25 – 90 kW/h (depends on laser power)

OEM & Production Note

This machine is manufactured under OEM production in Turkey.

Marking, laser power, automation level, and technical configuration can be determined on a project basis.

Related products

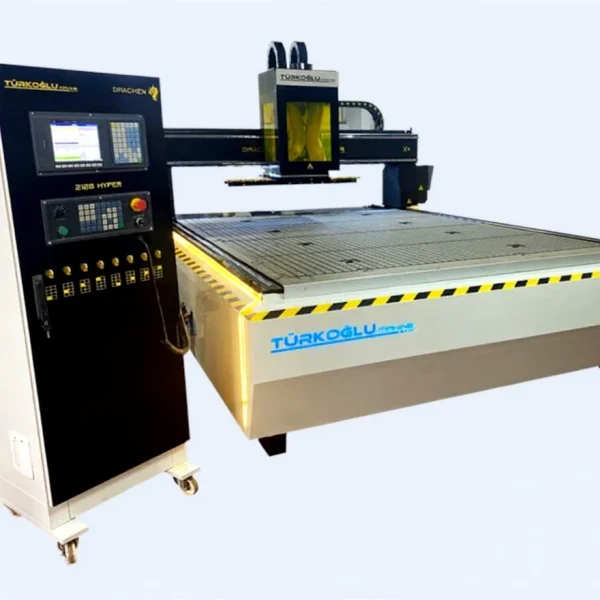

3 kW 1500×3000 mm Double Table Fiber Laser Metal Cutting Machine

In stock

| Brand | Xenon Lazer |

|---|---|

| Model Type |

3000 |

Plate And Pipe Integrated Laser Cutting Machine With Cover

In stock

| Brand | Sonko |

|---|---|

| Model Type |

JTLT Serisi |