650-2000 Kg/Hr Nut Roasting Oven

| Brand | Seintro |

|---|---|

| Model Type |

SF 10000 |

650-2000 Kg/Hr Nut Roasting Oven

Seintro SF 10000 is an advanced device designed for businesses seeking high efficiency and excellent quality, especially in the nut roasting industry, among belt type convection roasting ovens. It is ideal for roasting or drying a wide variety of nuts such as hazelnuts, almonds, sunflower seeds, pumpkin seeds, peanuts, pistachios, cashews, as well as spices, medicinal herbs, fruits, and vegetables at desired temperatures and durations. This high-capacity oven offers a wide production range between 650 kg/hr and 2000 kg/hr, allowing efficient management of large-scale production processes.

SF Series roasting ovens roast products moving on a belt by applying air at the desired temperature through fans. The oven also ensures homogenous roasting of products by providing humidity control inside the cabin. With the independent multiple cabin structure, separate temperature control can be performed for each cabin. This enables precise adjustment of roasting conditions for different types of nuts or products. Ideal air circulation ensures that products receive hot air equally on all sides, supporting efficient and homogenous roasting process.

The machine's structure made of AISI 304 quality stainless steel provides hygienic production while guaranteeing long-term durability. Stainless steel material is resistant to corrosive agents, enhancing the machine's longevity by allowing it to operate without losing performance even under high temperatures and intensive use.

The oven's exhaust system releases waste gases from the burners to the outside without coming into contact with the product, ensuring healthy production and preserving the aroma of the products. This is a critical feature for maintaining the natural flavor and quality of roasted nuts. Additionally, while the roasting process takes place on the belt, the products are cooled in the cooling cabin and removed from the oven. This ensures continuous production without capacity loss.

With the touch screen control panel (HMI Panel) of SF 10000, parameters such as cabin temperatures, belt speed, and product thickness can be easily adjusted. This allows operators to achieve desired color and flavor values. Moreover, these adjustments can be turned into recipes and saved for process repeatability, enabling each production stage to be repeated with the same quality.

Thanks to its ergonomic design, usage, maintenance, and cleaning processes of the machine are quite easy. Features such as belt washing system, motor-driven belt brushing system, and automatic control of cabin humidity exhaust fans minimize the machine's maintenance requirements and improve operational efficiency. Safety measures such as lid safety sensors, fan fault detection system, and belt safety system also ensure the machine operates safely.

This high-performance roasting oven reduces businesses' costs by offering low energy consumption and high efficiency. Energy loss is minimized thanks to heat insulation, which has a positive impact on energy bills in the long run. The oven can operate with different fuel types such as natural gas, propane, diesel, providing flexibility and economic operation.

…

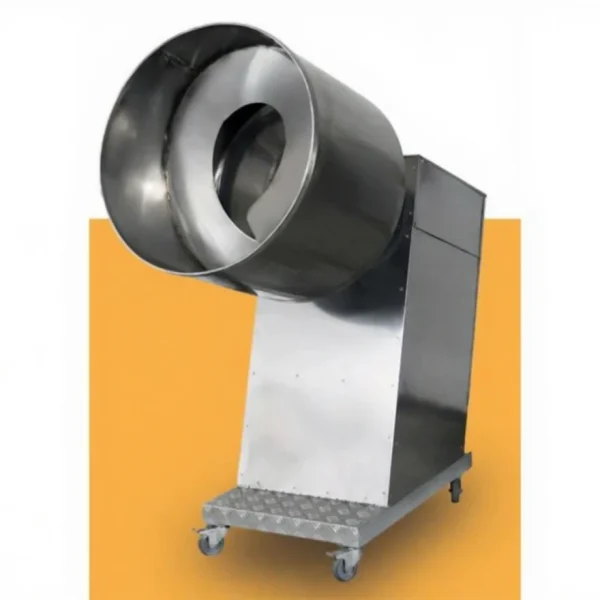

Related products

2 kg Yellow Roasted Chickpea Pumpkin Seed Sunflower Seed Peanut Spotting Machine

In stock

| Brand | Alpnuts |

|---|---|

| Model Type |

BM 2 |

50 kg Yellow Roasted Chickpeas Pumpkin Seed Sunflower Seed Peanut Spotting Machine

In stock

| Brand | Alpnuts |

|---|---|

| Model Type |

BM 50 |