65mm Plaka Kaynak Ağzı Açma Makinesi

| Brand | Graebener |

|---|---|

| Model Type |

G-KA-005 |

Graebener Plaka Weld Seam Opening Machines

For perfect welding performance, the preparation of the plate welding seam opening must be done accurately and correctly. Graebener® plate weld seam opening machines offer you the most effective and economical solutions to achieve the best results. Benefit from our technical expertise based on years of experience and master high-speed, precision, and reliability in processing all welding seam geometries.

Overview

Graebener® weld seam opening machines are designed based on our many years of technical expertise. You can benefit from the extensive experience we gained as our customer and partner in our own pipe factory between 1974-1997. Thanks to this experience, we know that high precision in processing plate edges can only be achieved if the plates remain welded throughout the entire processing time. Especially in large-format plates, your Graebener® plate weld seam opening machine will further increase the economic efficiency in plate edge processing.

Main application areas include shipbuilding, wind tower construction, bridge construction, shipbuilding, and equipment manufacturing. In addition, our customers also include plate rolling mills and steel service centers.

Compared to alternative plate edge processing methods, the advantages of milling technology are much greater. We fully utilize these advantages.

OUR SOLUTIONS ARE EXTREMELY IDEAL FOR A VARIETY OF PLATE SIZES.

|

Plate length: |

Up to 20 meters |

|

Wall thickness: |

Up to 65 mm |

Machine Concepts

Graebener® plate weld seam opening machines should no longer be seen as standard solutions. As a custom machine manufacturer, we have been experts in machine concepts for years considering the constantly increasing requirements in the quality of weld seam preparation. These concepts are tailored to your individual requirements, in addition to the material and quality classes used. Our mission is to do our best to make your Graebener® machine more successful, whether you need a new machine or a refurbishment solution.

We find the most suitable solution for you based on the following machine concepts (we can also produce other solutions with alternative machine concepts according to your specific specifications. Please contact us):

Graebener® Single or Double Milling Head 1-Sided Plate Weld Seam Opening Machine, Type GPE

-

Various sizes of small or medium plate lots

-

Standard tolerance requirements regarding flatness and parallelism

-

High precision on the base surface

Graebener® 2-Sided Plate Weld Seam Opening Machine, Type GPZ

-

Various sizes of medium plate lots

-

High tolerance requirements for flatness and parallelism

-

High precision on the base surface

Graebener® 4-Sided Plate Weld Seam Opening Machine System, Type GPZ-V

-

Various sizes of medium plate lots

-

High tolerance requirements for flatness and parallelism

-

High precision on the base surface

Graebener® 2-Sided Milling Plate Weld Seam Opening Machine, Type GPD-Z

-

Medium or large plate lots in various sizes

-

High tolerance requirements for flatness and parallelism

-

High precision on the base surface

ADVANTAGES

All Graebener® plate weld seam opening machines have a proven design that operates reliably even under the most challenging conditions. We avoid using additional turning devices that may be subject to wear or malfunction. Even after years of use, your Graebener® machine will continue to operate with high accuracy, speed, and reliability. Benefit from the technical advantages of your Graebener® plate weld seam opening machine.

-

The milling process does not cause additional stress on the plate due to heat – recyclable milling chips dissipate the heat

-

You obtain a metallic shiny surface

-

High parallelism on milled edges

-

You can benefit from our excellent plate clamping system:

-

High adaptability rate

-

Uniform weld seam opening

-

Less wear on milling tips

-

Less vibration

-

-

Plates are automatically measured

-

Low environmental impact due to low noise, dust, and heat emission

-

Both U-groove seams and chamfering are possible

-

Electronic copying of plate waves provides a center-focused milling profile

-

Depending on the machine type, plates can be placed inside the machine, no need for overhead crane

-

You can also process coated plates depending on the design

Related products

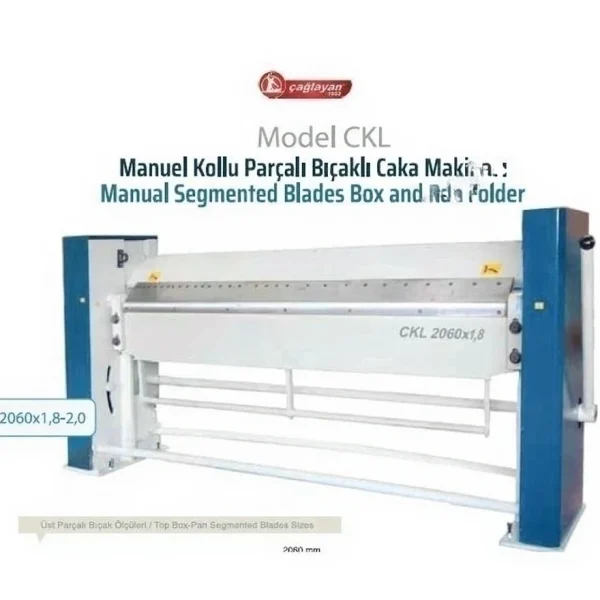

CKL 2060X1,8-2,0 Manual Hinged Blade Caka Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

CKL 2060×1,8-2,0 |

RM 1550X90 2.0 (3 Group) Motorized Roller Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

RM 1550×90 |

RST-M 1270X86X2,5 (3-Piece) Motorized Reinforced Roller Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

RST-M 1270x86x2,5 |