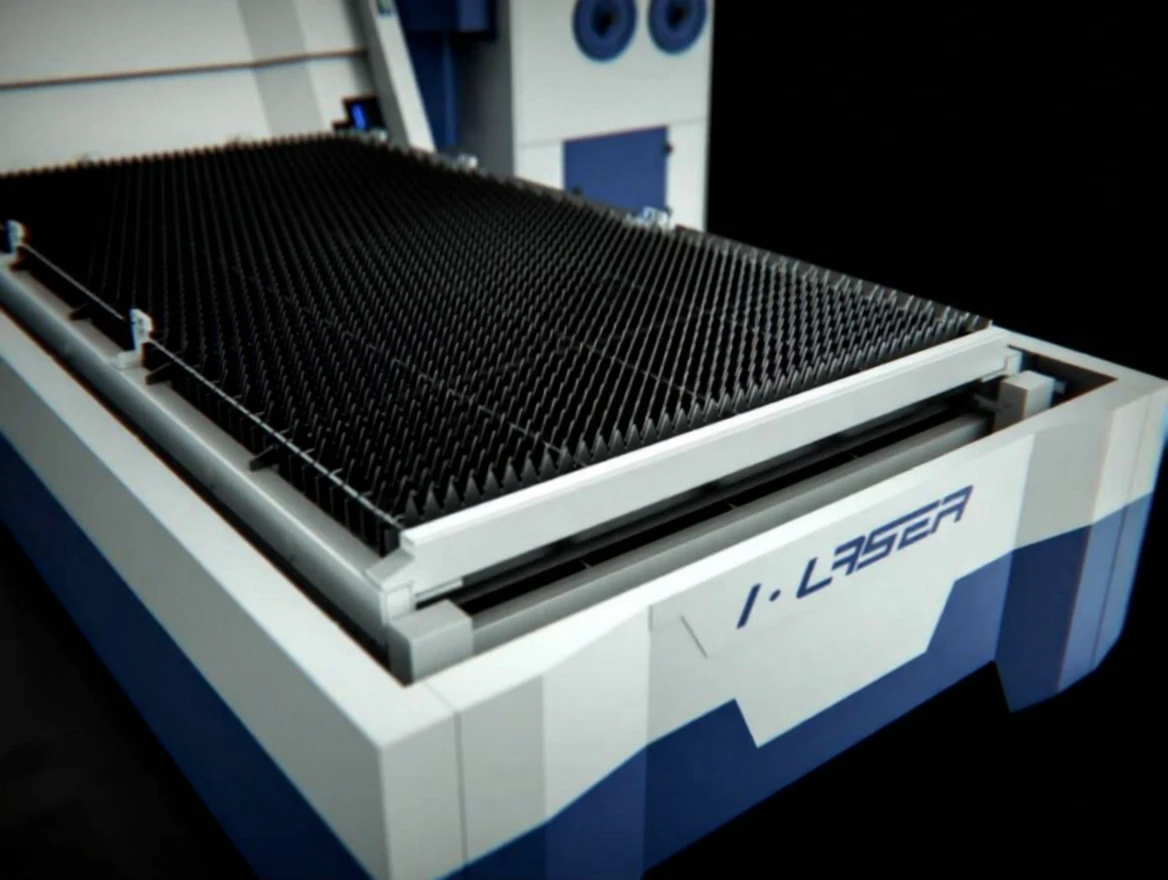

8000×2000 mm Fiber Laser Sheet Cutting Machine

| Brand | Cronosstech |

|---|---|

| Model Type |

FB 8020 |

FB 8020 – Fiber Laser Sheet Cutting Machine (OEM | Made in Turkey)

Working Area: 8000 × 2000 mm (8020 Model)

Short Product Description

FB 8020 Fiber Laser Sheet Cutting Machine; is a OEM production solution developed for applications requiring high speed, stability, and precision in large sheet sizes. Its heavy-duty steel construction, advanced CNC infrastructure, and high laser power options ensure full compatibility with mass production and heavy industry lines.

Key Advantages

-

OEM production – Made in Turkey

-

8000 × 2000 mm wide working area

-

Thick sheet cutting performance with high laser powers

-

Maximum operator safety with fully enclosed cabin

-

Structure suitable for automation and line integration

-

Stable, repeatable precision in long sheets

Standard Features

-

CNC controlled fiber laser sheet cutting machine

-

High rigidity, analyzed heavy-duty steel body and bridge structure

-

Rack-pinion drive system

-

Automatic motorized focusing laser cutting head

-

Capacitive sensor-based automatic height control system

-

Automatic focal distance adjustment during cutting

-

High precision linear guides and servo motor system

-

Windows-based, touch CNC control unit

-

User-friendly CNC interface with multiple language support

-

EtherCAT communication infrastructure

-

Monitoring of temperature, pressure, protective glass, and back reflection at the cutting head

-

Camera-supported monitoring system inside and outside the machine

-

LED status and warning indicators

-

Transmission of the fiber laser beam via fiber cable

(no optical mirror/lens loss) -

Automatic sheet recognition and alignment systems

-

Fly-Cut (continuous series cutting) feature

-

No Piercing (non-blasting cutting) mode for thin sheets

-

Controlled blasting cutting mode for thick sheets

-

Fully enclosed cabin compliant with CE standards

-

Special safety glasses that do not transmit laser light

-

CNC controlled filtered ventilation system

-

Automatic nozzle cleaning and cutting head calibration

-

Conveyor-based slag and part discharge system

-

Moving table system

-

Emergency stop buttons and safety locks

Optional Features

-

Double pallet automatic table exchange system

-

Fiber laser resonator in different power options

-

Automatic sheet loading system

-

Automatic part unloading system

-

Advanced CNC controlled filter unit

-

Camera-based automatic sheet recognition and nesting software

-

Remote monitoring and reporting package

-

Oil cooler / climate control system

-

Additional LED lighting inside the cabin

-

Special cutting head alternatives

-

Additional gas control and pressure regulation systems

Technical Specifications – 8020 Model

Axes

-

X Axis: 8030 mm

-

Y Axis: 2030 mm

-

Z Axis: 120 mm

Movement Performance

-

Acceleration: 2.0 G

-

Max. axis speed: 140 m/min

-

Synchronized speed: 200 m/min

-

Positioning accuracy: ±0.05 mm

-

Repeatability accuracy: ±0.03 mm

Table & Loading

-

Max. table loading capacity: 3500 kg

-

Table change time (optional): ~35 sec

Laser Power Options

-

4 kW / 6 kW / 8 kW / 10 kW / 12 kW / 15 kW

Cutting Capacities (Max.)

-

Black sheet: 25 – 40 mm (depends on laser power)

-

Stainless steel: 10 – 30 mm

-

Aluminum: 10 – 30 mm

Gas Pressures

-

Oxygen: 13 bar

-

Nitrogen: 25 bar

-

Air: 13 or 25 bar

General

-

Machine weight: ~32,000 kg

-

Average electricity consumption: 30 – 110 kW/hour

(depends on laser power)

OEM & Production Note

This machine is manufactured under OEM production in Turkey.

Marking, laser power, automation level, and technical configuration can be determined on a project basis.

Related products

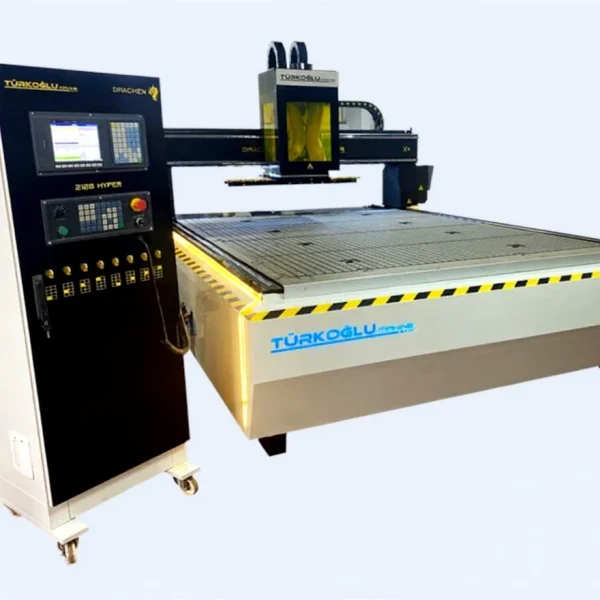

3 kW 1500×3000 mm Double Table Fiber Laser Metal Cutting Machine

In stock

| Brand | Xenon Lazer |

|---|---|

| Model Type |

3000 |