80mm Boru Kaynak Ağzı Açma Makinesi

| Brand | Graebener |

|---|---|

| Model Type |

G-KA-003 |

Graebener Pipe End Weld Edge Opening Machine

Technology suitable for all needs: Graebener® pipe end welding edge opening machine brings even the most complex seam geometries and coating processes to life at low cost. With our special CNC controlled machine concepts, you can achieve the best results for outer pipe diameters up to 98 inches (2,490 mm) and wall thicknesses up to 80 mm.

Overview

Graebener® pipe end welding edge opening machines are always raising the standards in preparing welding seams of pipe ends. While mechanical copying devices have required a fixed web width as a technological standard for years, we have designed an additional “all-in-one” technology that allows you, the machine operator, to process carbon steels as well as other material types optimally. A single machine with both mechanical copying and CNC copying- for all welding seam geometries, unilateral or bilateral design as needed.

When considering constantly changing quality standards, common pipe end welding edge opening processes fall short when complex geometries and high wall thickness pipes are involved. Thanks to the precise CNC control in the tool support unit of your specially designed Graebener® machine, you can now process pipes with wall thicknesses up to 80 mm and bring even the most complex welding edge geometries to life individually and at a low cost. Mechanical copying can be done in lower wall thicknesses and relatively simple geometries.

OUR SOLUTIONS ARE EXTREMELY IDEAL FOR A VARIETY OF PLATE SIZES.

|

Pipe length: |

Up to 18 m |

|

Outer Pipe Diameter: |

Up to 98″ (2490 mm) |

|

Wall Thickness: |

Up to 80 mm |

Large Pipes. Thick Plates.

We understand your processes: As your experienced partner, we accompany you from the first plate processing to the optimum pipe or pipe section. Holistic, individual, customer-oriented: Graebener® makes a difference.

Machine Concepts

Graebener® pipe end welding edge opening machines should no longer be seen as standard solutions. As a custom machine manufacturer, we have been a professional expert on machine concepts for years, considering constantly increasing requirements in the preparation quality of welding seams. These concepts are customized based on the material and quality classes used, as well as your individual requirements. It is our duty to do our best to make your Graebener® machine more successful.

Therefore, the design of Graebener® 1-sided and 2-sided pipe end welding edge opening machines has proven reliability and success under the most challenging industrial conditions worldwide. There is a sturdy and durable machine bed that can move longitudinally on rails. The CNC transverse slide has a universal design that can adapt to various tools and measuring devices. The pipe clamp is an operator-friendly and modular system designed to offer you, the machine operator, the highest flexibility in production and minimize tool change time.

Based on your personal needs, we find the most suitable solution for you by starting from the following machine concepts:

Graebener® 1-Sided CNC Pipe End Welding Edge Opening Machine, Type GEB

-

Mechanical copying and processing unit for thin wall thicknesses

-

CNC controlled copying and processing unit for welding seam preparation in complex structures and pipes with high wall thicknesses

-

Pipe end ovality measurement

Graebener® 2-Sided CNC Pipe End Welding Edge Opening Machine, Type GEB-Z

-

Mechanical copying and processing unit for thin wall thicknesses

-

CNC controlled copying and processing unit for welding seam preparation in complex structures and pipes with high wall thicknesses

-

Pipe end ovality measurement

-

Integrated pipe length measurement for processing a pipe to the correct length

CNC Advantages

Only the best technology is used for excellent results. Our CNC technology automatically takes into account the ovality on the pipe end at high wall thicknesses, ensuring a constant web width. This is possible with an electronic measuring system that measures the ovality of the pipe from center to center along the entire circumference electronically. In this way, deviations from the theoretically defined pipe center can be graphically displayed.

Your Graebener® machine generates a specific number of data for each type of pipe end, and these data are processed in the CNC software for automatic correction of the tools. There is no need to account for the welding seam during processing, because the seam is perceived as inaccurate measurement based on precise measurement data by intelligent control software, and compensated during processing.

In addition, the electronic measuring system- in the 2-sided machine concept- automatically measures the pipe length and thus ensures that the pipe is set correctly in the desired shape.

Related products

5 Ton Horizontal Inverter Adjustable Sheet Metal Uncoiler

In stock

| Brand | Parola Makina |

|---|---|

| Model Type |

5 Ton |

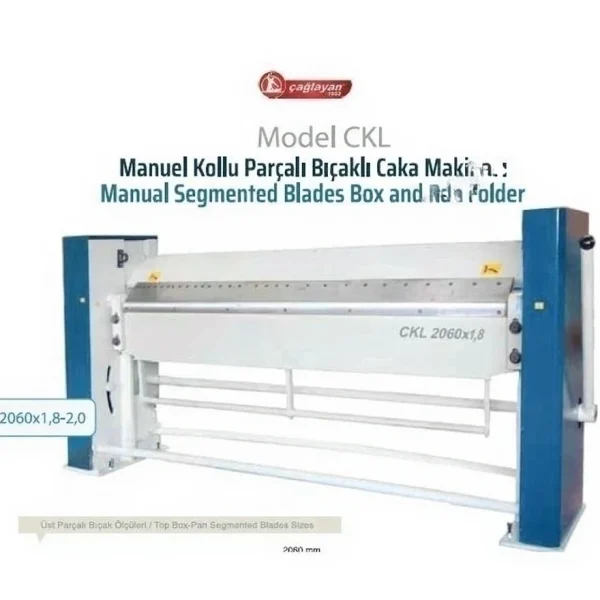

CKL 2060X1,8-2,0 Manual Hinged Blade Caka Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

CKL 2060×1,8-2,0 |

HNM 6 VP (6 mm) Hydraulic Angle Adjustable Corner Cutting

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

HNM – 6 VP |

RST-M 1270X86X2,5 (3-Piece) Motorized Reinforced Roller Machine

In stock

| Brand | Çağlayan Makas |

|---|---|

| Model Type |

RST-M 1270x86x2,5 |