9000 Liter Combined Surface Dressing Vehicle

| Brand | ATS Asfalt |

|---|---|

| Model Type |

ASKA |

Category: Asphalt Machinery and Equipment

Description

9000 Liter Combined Surface Dressing Vehicle

The Combined Surface Dressing Vehicle is an innovative hybrid vehicle capable of simultaneously performing bituminous surface and aggregate spreading operations. This unique feature allows tasks that usually require two separate vehicles to be completed with a single vehicle, increasing efficiency and reducing costs.

Bitumen and aggregate materials are applied within 1 second, creating a high-quality bond that ensures the construction of safer and longer-lasting roads.

Advantages

- Reduced Labor and Vehicle Usage: Lower workforce and vehicle requirements enhance environmental protection and energy efficiency.

- Ease of Use: The vehicle driver can easily perform all necessary adjustments during the application using the touchscreen and control buttons located in the driver's cabin. All spraying and cleaning operations can be managed from the cabin.

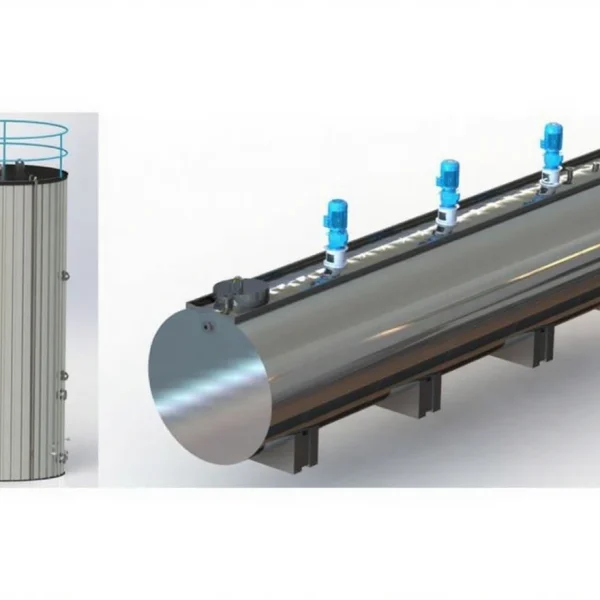

- High-Capacity Bitumen Tank: The highly insulated bitumen tank has a capacity ranging from 6,000 to 9,000 liters, meeting high standards.

- Efficient Heating System: The burner system heats the entire bitumen line using a hot oil heating system.

- Large Aggregate Hopper: The 10 m³ capacity aggregate hopper is designed for uniform spreading.

Additional Features

- Optional Equipment: A bitumen spray gun and rearview camera can be added upon request.

- Energy Efficiency and Easy Process Monitoring: A design that enhances energy efficiency and simplifies process monitoring.

- Low Maintenance and Repair Costs: The easy accessibility of parts and equipment minimizes maintenance and repair expenses.

Technical Specifications

- Bitumen Tank Capacity: 6,000 – 9,000 L

- Aggregate Hopper Capacity: 10 m³

- Heating System: Hot oil heating system

- Control System: Operated from the driver's cabin using a touchscreen and control buttons