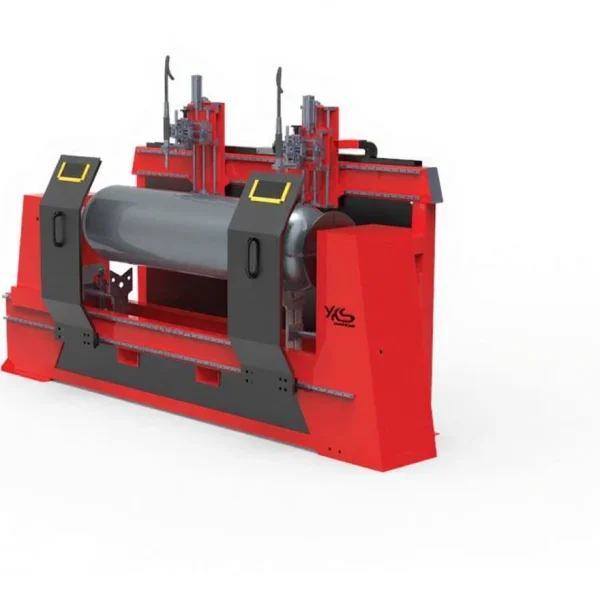

Automatic Sequential Sleeve Welding Machine

| Brand | Mavera |

|---|---|

| Model Type |

MVR_OMKM_9002 |

Automatic Sequential Sleeve Welding Machine

The automatic sequential sleeve welding machine is designed for fast, precise, and repeatable welding of multiple sleeves placed in different positions on products such as air tanks, boilers, expansion tanks, LPG tanks, pressure vessels, and hydraulic cylinder bodies.

This system moves automatically between defined positions without the need for operator intervention. It locates each sleeve in its axis and performs the welding process. The advanced control unit allows programming of sleeve clearances, angles, and welding parameters. This feature ensures high speed and standard quality in mass production.

The machine is controlled both via a touch panel and allows for recipe (program) recording for each product type. Prior to production, a welding-free simulation test can be performed. Features such as oscillation, rotary table, moving lower table, and welding curtain can also be optionally offered with this machine.

Areas of Use

-

Air tank manufacturing

-

Boiler and expansion tank production

-

Production of pressure vessels and LPG tanks

-

Parts for agricultural machinery

-

Multiple connection points in hydraulic cylinders

-

Sequential nozzle welding in industrial bodies

Key Features

-

Sequential sleeve welding in different positions

-

Automatic positioning and axial progression

-

Recipe (program) recording and fast product transition

-

Touchscreen controlled user interface

-

Pre-production test with welding-free simulation

-

Automatic positioning according to sleeve diameter

-

Oscillation-supported welding head

-

Rotary and/or moving table options

-

Integration of welding curtain (optional)

-

High repeatability and low error rate