Ceiling Crane Manufacturing

| Brand | BNR Makina |

|---|---|

| Model Type |

B-MG-001 |

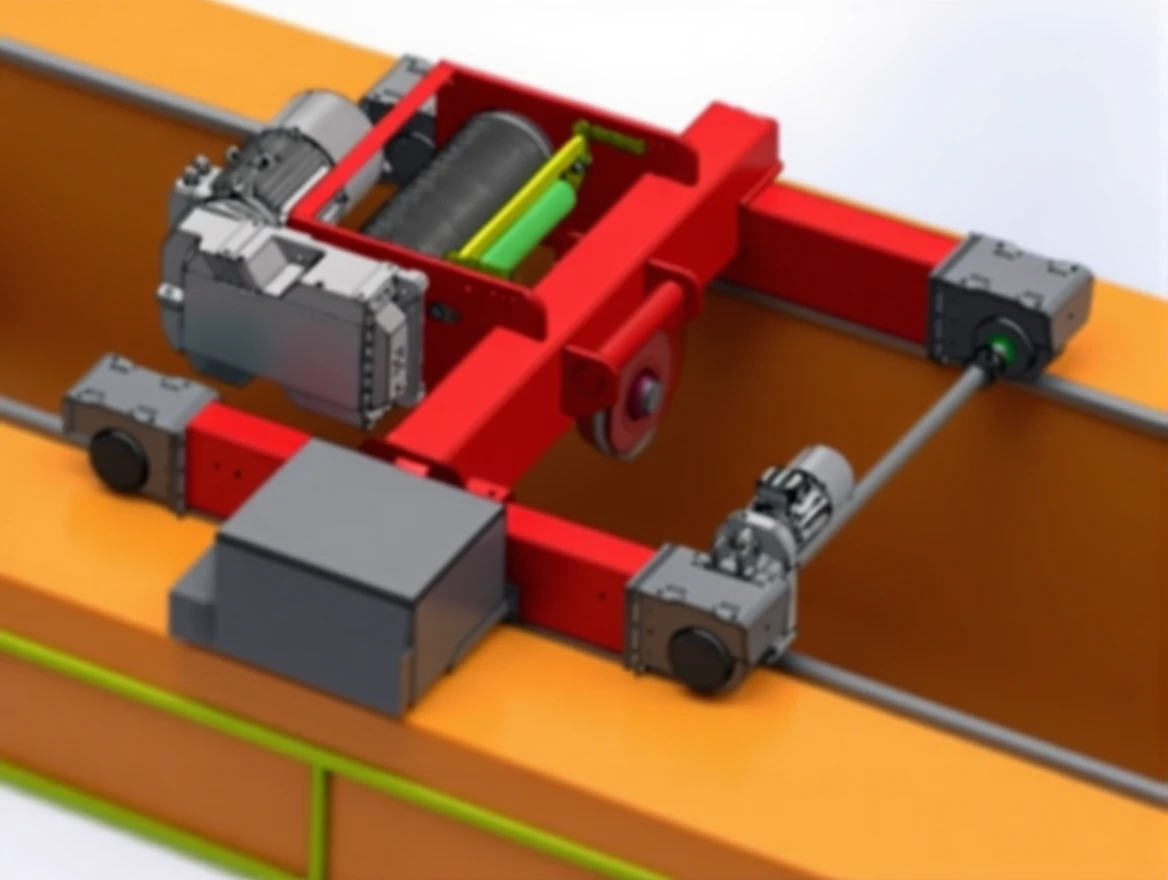

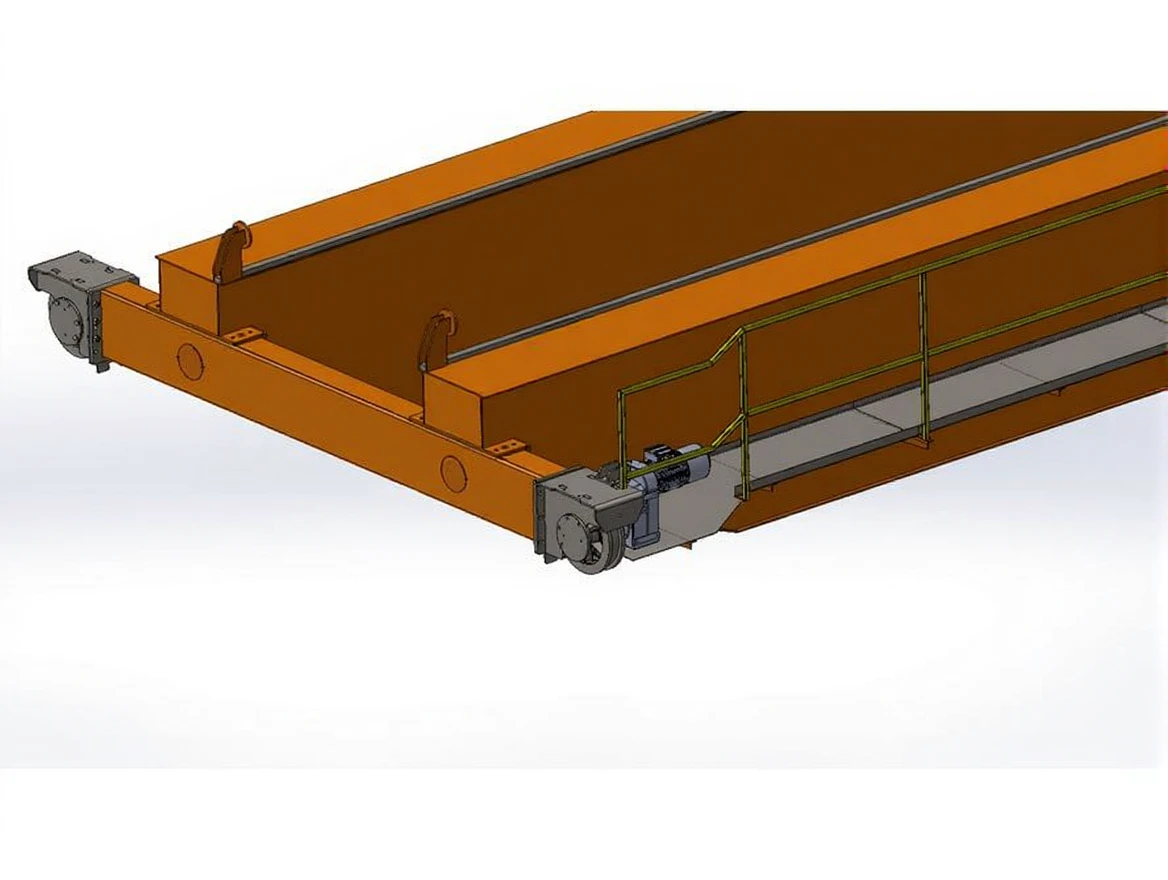

Ceiling Crane Manufacturing

It is one of the important machines used for lifting and transporting large and heavy loads in industrial areas. These cranes typically move on a rail mounted on a steel frame and can be used for a wide variety of tasks by covering a large area.

The ceiling crane is a type of crane that operates with a system mounted on the ceiling of factories or large warehouses, usually used for high-capacity lifting and transporting tasks. These machines are supported by a “bridge” that moves on the ceiling rail. They generally operate with a combination of mechanical, electrical, and electronic systems.

2. Features of Ceiling Cranes

-

Load Capacity: Ceiling cranes are produced with different capacities. Models that can lift loads between 1 ton and 100 tons are available.

-

Mobility: A ceiling crane can typically have three basic movements: forward and backward (horizontal), up and down (vertical), and side to side (lateral direction).

-

Safety: It is equipped with a series of safety measures to ensure the safe transportation of loads. This includes limit switches, emergency stop systems, and overload protection systems.

3. Ceiling Crane Manufacturing Process

The manufacturing process of ceiling cranes includes the following steps:

-

Design: The crane design is made according to user needs and load carrying capacity. At this stage, engineering and technical calculations are quite important.

-

Production: It includes metal processing, welding, assembly, and testing stages. This process requires high precision and quality material selection.

-

Testing and Quality Control: After production is completed, the cranes are tested to see if they operate safely. Load tests, vibration control, and functional tests are conducted at this stage.

4. Types of Ceiling Cranes

-

Bridge Ceiling Crane: This is the most common type of ceiling crane. It has a bridge structure that moves on a rail.

-

Monorail Ceiling Crane: It moves on a single rail and is usually used in smaller areas.

-

Only Elevated Ceiling Cranes: This type of crane is preferred in areas that are lower in height.

5. Areas of Use

Ceiling cranes are widely used in the following sectors:

-

Factories and production facilities: Transportation of heavy machinery, material handling on assembly lines.

-

Construction sites: Lifting and transporting construction materials.

-

Ports: Container loading and unloading operations.

-

Warehouses and logistics centers: Transportation of loads to storage areas.

6. Considerations in Ceiling Crane Manufacturing

-

Load carrying capacity: Choosing ceiling cranes with the correct capacity is very important for occupational safety.

-

Material quality: The steel and other materials used must have high quality and durability.

-

Maintenance and service: Regular maintenance of cranes ensures long life and safe operation.