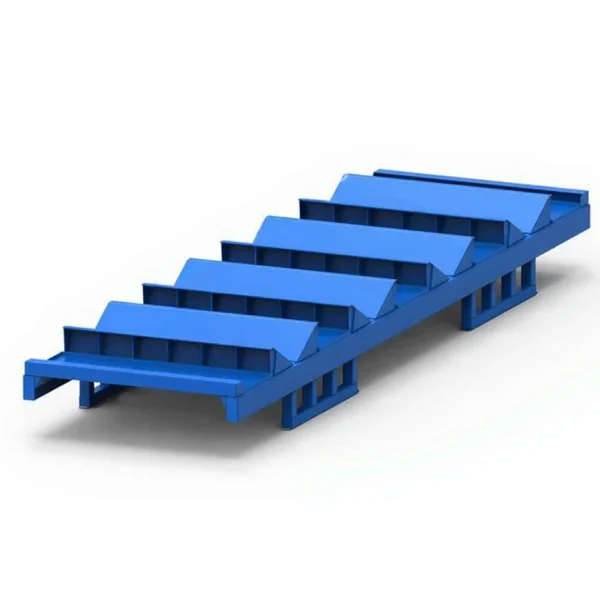

Container Loading and Unloading System

SmartTEH CLS/CLS-U

By being automatically activated, it significantly shortens the container loading time. This eases the traffic in the field, increases operational efficiency, and provides quick and concrete solutions to daily industrial changes.

Efficiency in Industry with Automatic Loading

-

Automation in timber loading: Leading companies like Stora Enso and HS Timber Group are using automatic loading systems in wood processing to increase efficiency, reduce product damage, and maximize space utilization. This reflects the industrial trend towards modern logistics solutions.

-

Automation in production logistics: WA Kaolin Limited demonstrates the use of automatic systems in loading kaolin in large bags. This method highlights the importance of automation in industrial logistics by reducing operational costs and loading times.

Practical Use and Fast Unloading

-

Steel products, heavy pallets, and other loads are safely unloaded with the system.

-

Fast operation: Saves time with a container unloading capacity of 5 minutes.

Benefits of the Container Loading and Unloading System

-

Maximum utilization of container space

-

Time and cost savings

-

Reduction of product damage

-

Improved safety for operators

-

Easy and safe loading process

-

Suitable for wrapped and secure packaging

System Features

-

Loading of all types of containers: 20, 40, and 45 feet

-

Loading capacity for containers up to 13.6 m long

-

Loading of difficult-to-transport cargo in a single trip

These automatic container loading and unloading systems accelerate your industrial logistics operations, enhance safety, and reduce costs. They provide an ideal solution for modern manufacturing facilities.