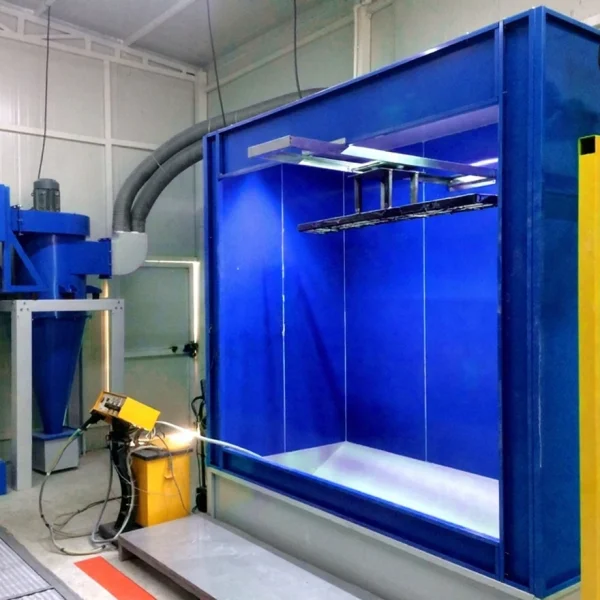

Cyclone Powder Coating Cabin

| Brand | Elektrosprey |

|---|---|

| Model Type |

SM DKP |

Spray Metal SM DKP

Cyclone Powder Coating Cabin

General Features

- Cyclone cabins consist of two separate units.

- The powder coating particles absorbed with air are thrown into the cyclone body with a 180-degree centrifugal rotation.

- The second vortex formed in the middle section directs the powder particles into the cyclone bucket over the cyclone cone.

- Small fractures formed as a result of fast-moving particles colliding with each other are directed towards the suction pipe in the middle and pass through the filter group into the defo tank.

- The powder coating that accumulates in the bucket during operation is taken at regular intervals, sieved, and returned to the gun.

- Cyclone cabins are used by businesses in the powder coating sector that have a lot of color changes.

- Cyclone cabins break down powder coating particles due to centrifugal effect.

- For this reason, the paints accumulated in the cyclone tank should be mixed with fresh paint before use.

Spray Metal SM DKP

Technical Specifications

-

Cyclone powder coating cabins are manufactured modularly from 1.5mm and 2mm DKP sheet metal.

-

Depending on preference, they can be made from galvanized sheet, PVC, or stainless steel material.

-

All parts of the cabin are disassembled and all connections are bolted.

-

The inner and outer surfaces of the cabins are coated with electrostatic powder paint.

-

Felt filters are determined according to the cyclone flow rate.

-

Felt filters have a dust retention capacity of 15 microns.

-

Reverse pressure is applied to the filters to prevent paint accumulation.

-

The fan used in the powder coating cabin is of the radiant type.

-

It is suitable for manual and automatic operations.

-

Special manufacturing is done outside of standard.