Facade Master 1250 Double Column Facade Working Platform

| Brand | 3K Asansör |

|---|

Category: Platform Elevator

Description

3K Elevator Facade Master 1250

Facade Master 1250 Double Column Facade Working Platform

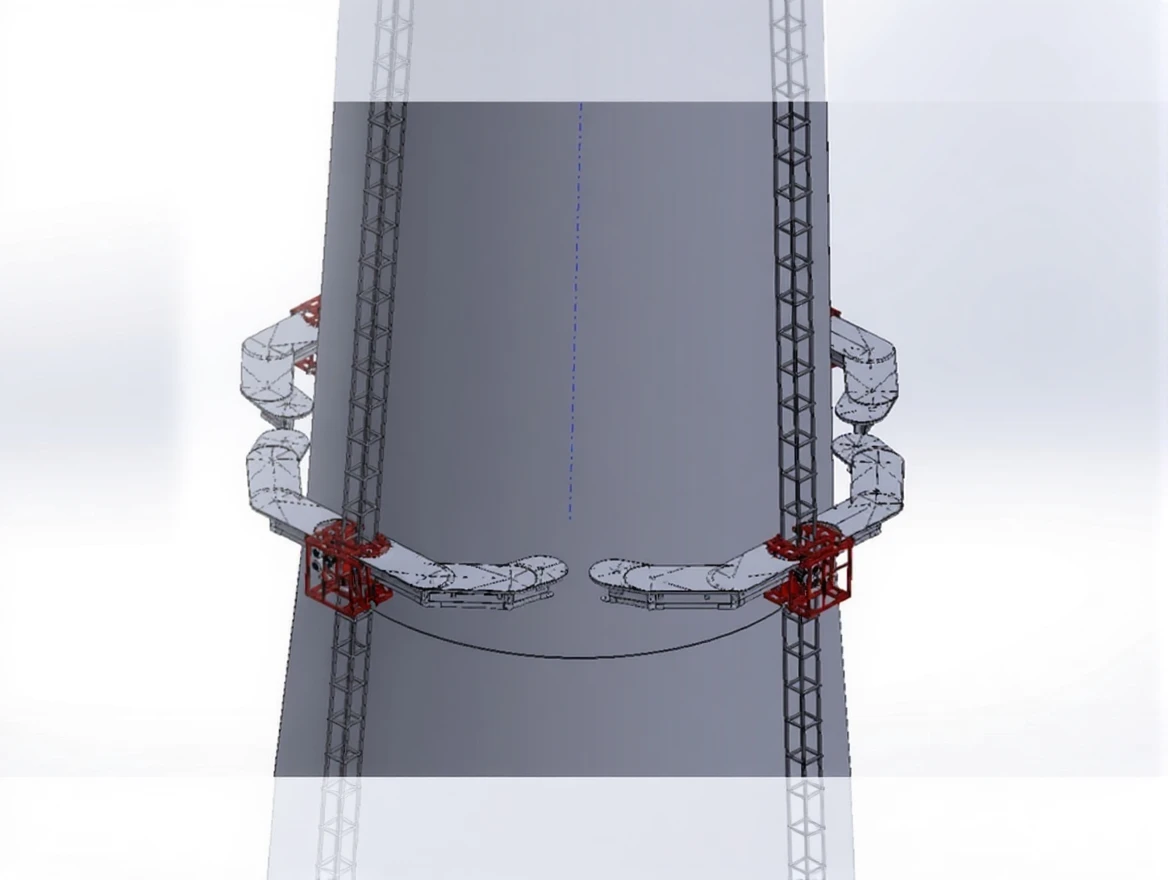

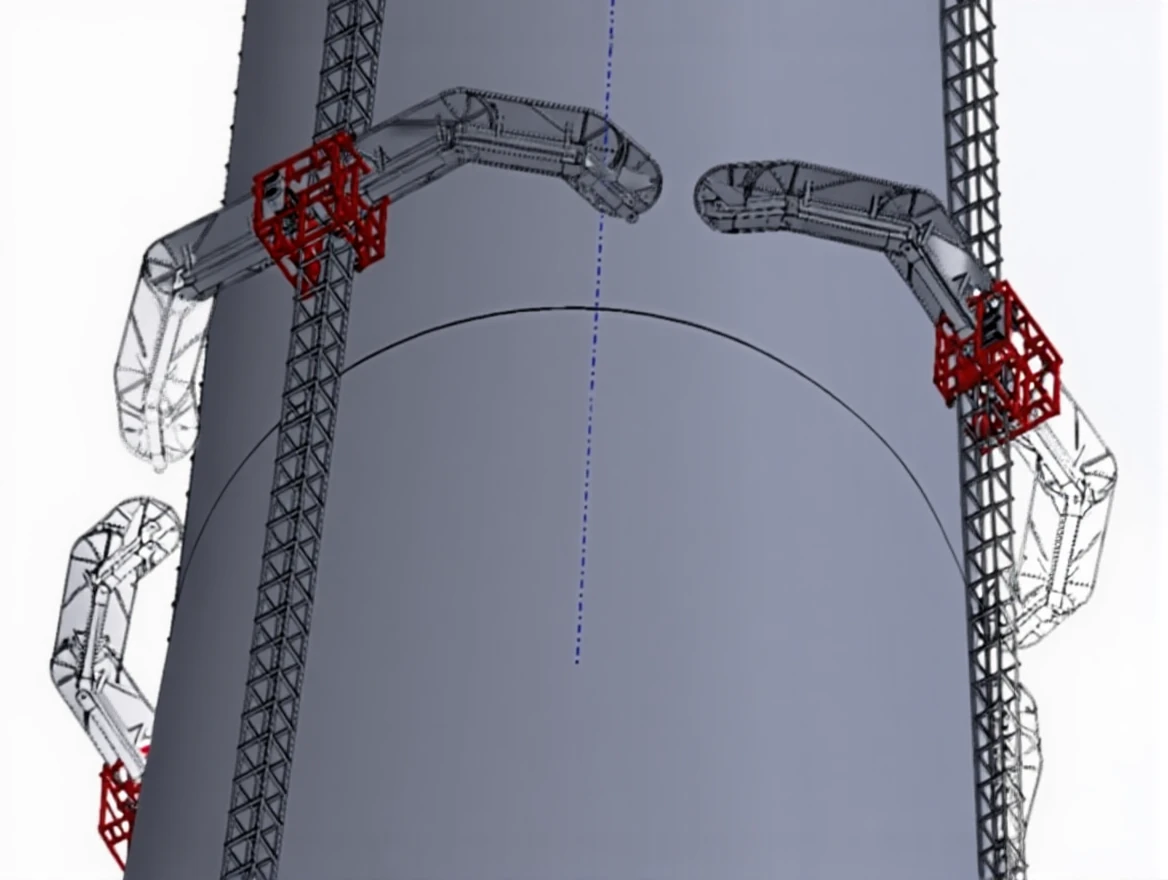

Facede Master (work platform on column) is an ideal machine that provides an area with a lift for working on building facades. It can carry up to 5 employees and a load of up to 3670 kg up to a 30 meter long frontage, as shown in tables 7 and 8 of the manual.

As a working principle, they are scaffolding systems that move with electric motors on steel masts mounted with anchor arms on the facade where the work will be done. These systems are modular systems that can be opened up to a width of 10.5 meters on a single mast and up to 30 meters on a double mast. At the same time, it can reach a height of up to 150 meters with the standard materials on the system.

The basis of the elevator system is based on the rotation of small gears on the gear ratchet. This rotation is produced by two identical and shared electronic motor groups. Each engine group combines a motor, an electronic brake, a gear reducer group and an emergency central braking system. These engine groups (from now on they may be called engines for short) are attached to a metallic structure called chassis. This structure supports the column, holds all moving parts of the machine and transfers all power to the column. It also has rail adjustment that prevents the machine from leaving its orbit and includes a high security detector as well as a door to access the platform from the outside.

Apart from the chassis, other mechanical elements can be connected to various parcels of the platform, thanks to screws, in line with the requirements, up to the maximum foresight in the manual. Each parcel of the platform consists of a metallic window cage, perforated plate floor, extension system and railings.

This entire set stands vertically thanks to the movement of small gears on the gear pawl and is fixed and welded to a column supporting this facade. Said column organizes a series of plots screwed together to a height of 150 meters. In addition to supporting the platform, it also acts as a guide. After the column is strengthened with the platform that gives the power to the ground, it provides stabilization until the moment of major collapse when the set is dispersed. The machine also has an electronic system that feeds the set and supports many movements such as a security system.

Referred to as a fixed chassis in the EN 1495:1998 norm, the body contains a center and stabilizers in the form of a tubular plane, as well as telescopic and rotating tubes that can be removed from the body when not in use.

The center body also includes threads to secure the first section. It also contains five axles: one at each corner of the square and one positioned in the middle, where the ratchet will support most of the load. It also contains four stabilizers, as just described, and these can be placed in many places on the base. These stabilizers are assigned to support the machine during its demolition phase for delivery. (see figure on next page)

3K Elevator Facade Master 1250 Double Column Technical Specifications

Engine Power (kW) 8.8

Basic Supply (Vac) 3×400/- 10%

Basic Supply (Hz) 50/- 5%

Control Circuit Voltage (V) 48

Control Circuit Frequency 50

Maximum Starting Intensity (A) 108

Maximum Consumption (KVA) 12

Magnothermic motors 3x25A

Thermal Motors 3×9/13A

Magnothermic Control Circuit (First) 2x3A

Magnothermic Circuit (Secondary) 1x6A

Current for Portable Tools (V,lac) 220.16

Minimum Feed (KVA) 15