Globe Valve Disc Manufacturing

| Brand | Unimek |

|---|---|

| Model Type |

UNMK-KI2 |

Globe Valve Disc Manufacturing

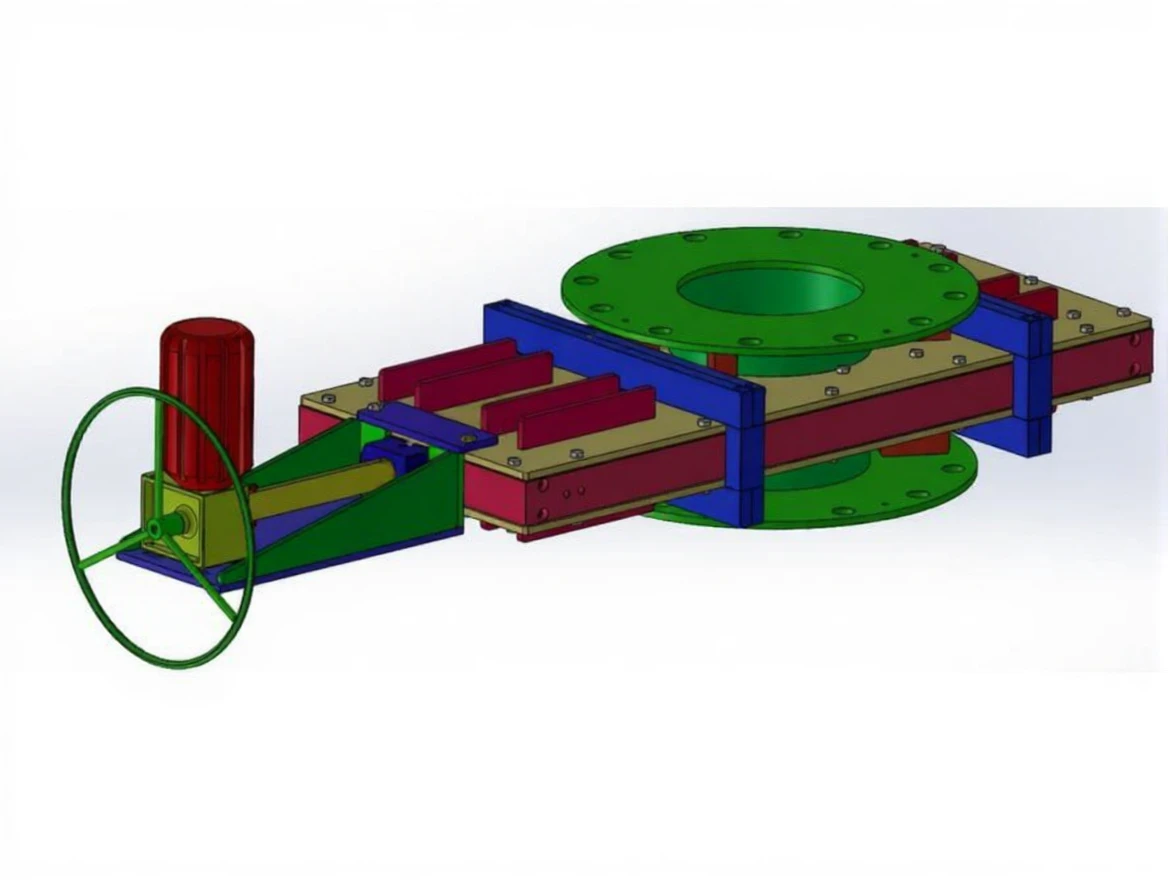

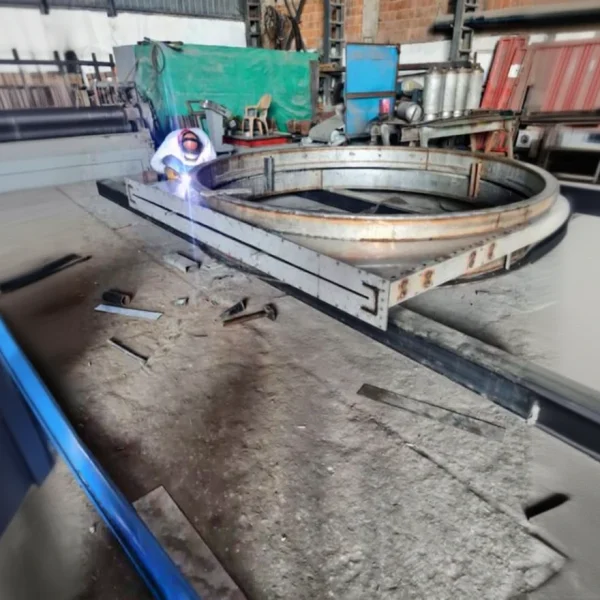

The manufacturing of flow control elements such as valves, discs, and globes is a process carried out with engineering precision and the use of high-quality materials. These products play an important role in all industrial facilities where flow control is required. The modern technologies used in the production process ensure that the products have a long lifespan, are durable, and operate with maximum efficiency.

Manufacturing Process

-

Design and Prototyping:

-

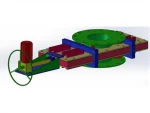

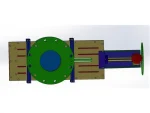

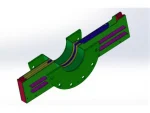

Designing the products in compliance with engineering calculations using CAD software.

-

Manufacturing prototypes that will undergo necessary tests and conducting detailed analysis.

-

-

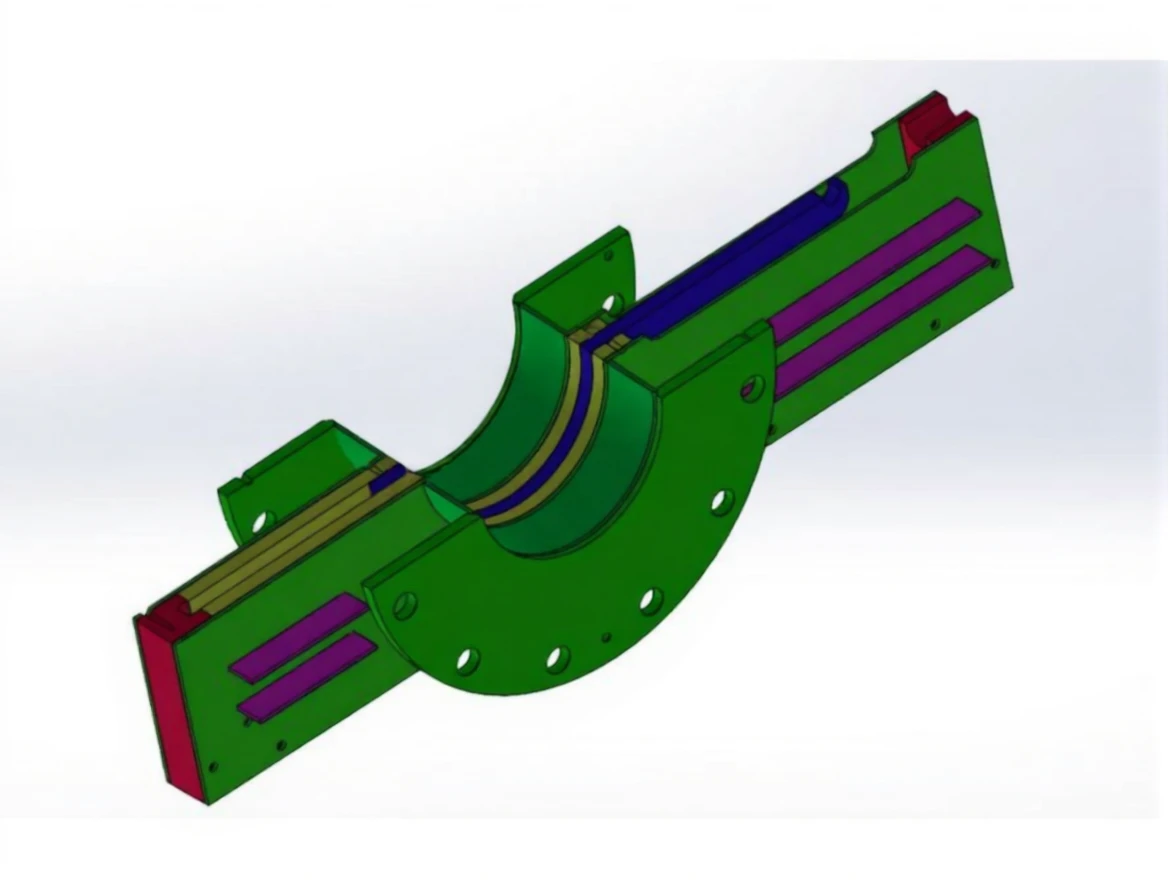

Material Selection:

-

Preference for materials like high-pressure and temperature resistant steel, stainless steel, and alloyed materials.

-

Application of coatings with high chemical resistance materials.

-

-

Production Stages:

-

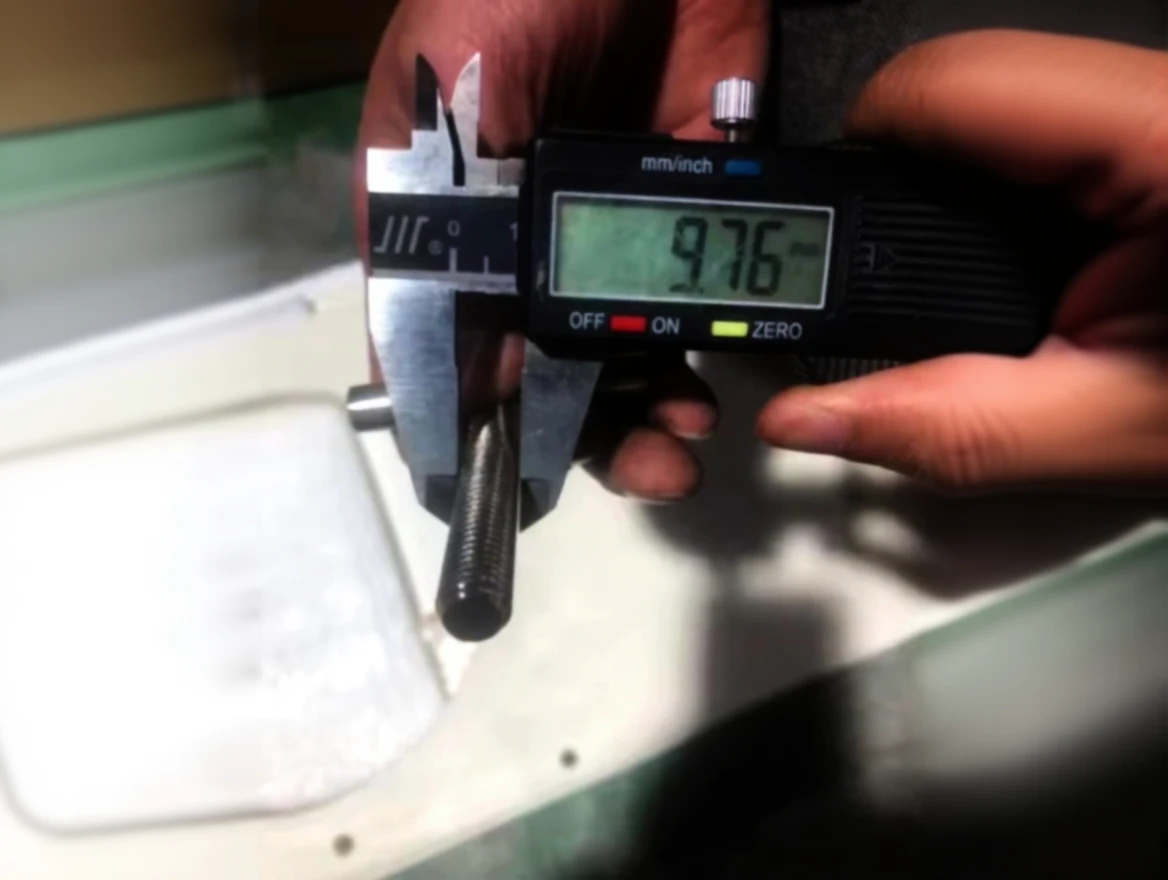

Precision machining on CNC machines.

-

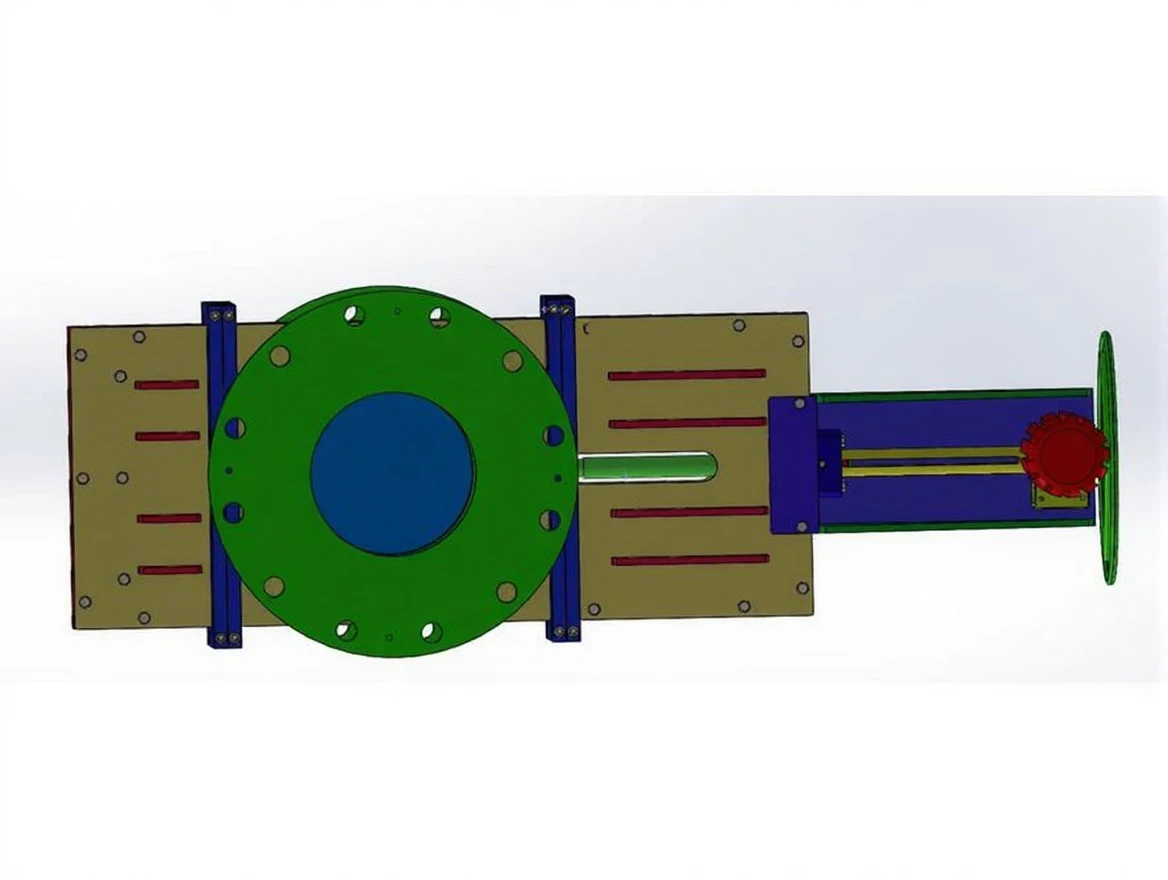

Production of flange and body connections in compliance with standards.

-

Proper alignment and testing of sliding mechanisms.

-

-

Assembly and Quality Control:

-

Assembling all components and conducting leak tests.

-

Verification of product reliability through pressure resistance tests.

-

-

Surface Treatment and Coating:

-

Application of electrostatic paint or galvanized coatings to enhance resistance against rust.

-

Product Advantages

-

Durability: Long-term use in challenging conditions due to high-quality materials and production techniques.

-

Precise Control: Regulating flow with sliding and manual control mechanisms with precision.

-

Modular Design: Easily integrable with different pipe systems.

Areas of Use

-

Water and wastewater treatment plants.

-

Chemical, oil, and energy sectors.

-

Agricultural and irrigation systems.

-

HVAC (Heating, Ventilation, and Air Conditioning) applications.