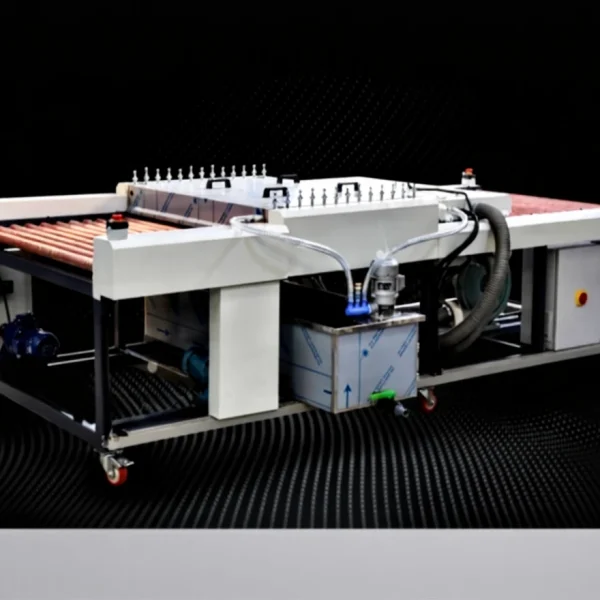

Automatic Glass Cutting Table for Lying Down and Standing Up

Bottero S.P.A. 352 BCS

|

TECHNICAL INFORMATION

-

Loading, cutting, and breaking operations are all performed on the same machine.

-

Air coming from fans circulates through welded profiles to create an air cushion between the table surface and the glass.

-

The table surface is coated with a special cushion.

-

Electronic edging is done without the need for front and side edging wedges using a special laser.

-

The lying-down and standing-up movement of the table is provided by hydraulic cylinders.

-

The lying-down and standing-up movement of the table and the operation of the edgers and fans are controlled by control buttons placed on the long side of the table.

-

Breaking bars operated by a pneumatic system are controlled by pedals located at the bottom of the table. Each pedal controls the breaking bar closest to it.

-

The edges of the table are covered with hard wood to ensure smooth glass breaking by hand.

-

This machine is capable of performing all types of straight, diagonal, and shaped cuts in a perfect and fully automatic position.

-

The cutting bridge is mounted on the machine with a gear system located opposite each other.

-

The bridge movement is provided by pinion gears moving on a vertically mounted rack-and-gear system.

-

The cutting head moves on the bridge by means of a gear mechanism directly connected to a motor.

-

Cutting pressure adjustment can be finely adjusted from the computer. The cutting pressure adjustment can be made accurately from the computer.

-

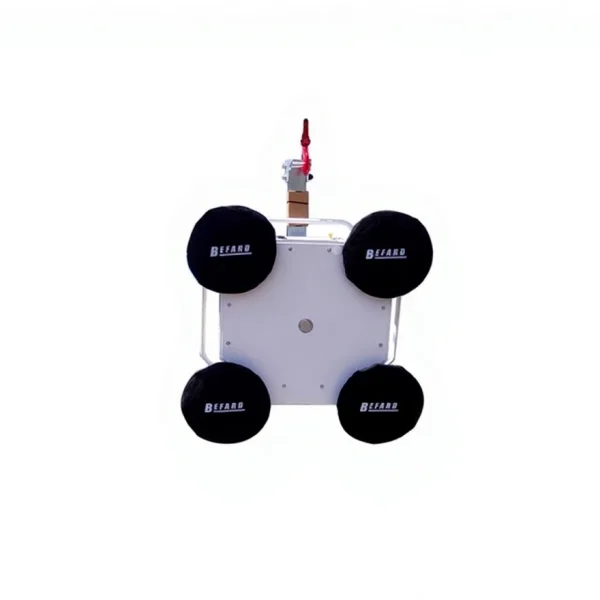

In the cutting lubrication system, the oil flow can be adjusted to the most suitable level. With the oil adjustment valve in the lubrication system, the oil flow can be adjusted to the most suitable level.

|

|

Option

-

Shape Scanner (Shape Scanning System)

With Bottero’s patented system, shapes with unknown or geometric dimensions can be dimensioned using shape scanning on the cutting table. A shape template made of wood, glass, or cardboard is randomly placed on the cutting bridge.

By activating the scanning system placed on the cutting bridge, shape dimensions are transmitted online to the computer.

The shapes placed into the plate become ready for cutting. 20 shapes can be scanned at the same time.

The shape scanning operations are performed entirely from the computer using the mouse. Scanned shape information is automatically transferred to the computer.

|

| GENERAL TECHNICAL SPECIFICATIONS |

MACHINE DIMENSIONS |

JUMBO DIMENSIONS |

|

| TABLE DIMENSIONS |

4600 x 3500 mm |

7000 x 4000 mm |

| WEIGHT |

1800 kg. (Approximate) |

2250 kg. |

| MAXIMUM GLASS SIZES TO BE CUT |

3650 x 2750 |

6100 x 3300 mm |

| MAX. AND MIN. GLASS THICKNESSES TO BE CUT |

2 – 19 mm |

2 – 19 mm |

| ADJUSTABLE TABLE HEIGHT |

880 – 920 mm |

880 – 920 mm |

| LONGITUDINAL BREAKING BARS QUANTITY |

1 |

1 |

| TRANSVERSE BREAKING BARS QUANTITY |

1 + 1 (OPTIONAL) |

2 + 1 (OPTIONAL) |

MAXIMUM CUTTING TOLERANCE

WHEN THE MACHINE OPERATES AT 100 M/MIN. MAXIMUM CUTTING TOLERANCE |

+/- 0.25 mm

+/- 0.15 mm |

+/- 0.25 mm

+/- 0.15 mm |

| DIAGONAL CUTTING TOLERANCE ( If less than 2 m2 |

|

‘ )

0.5 mm |

1 mm |

| DIAGONAL CUTTING TOLERANCE ( If more than 2 m2‘ ) |

1.0 mm |

2 mm |

| SHAPED CUTTING TOLERANCE |

+ / -0.3 mm |

+ / -0.3 mm |

| FLATNESS |

0.5 mm |

0.5 mm |

| REPEATABILITY |

+ / – 0.15 mm |

+ / – 0.15 mm |

| MAX. CUTTING SPEED |

120 m / min |

120 m / min |

| POWER CONSUMPTION |

12 kVA |

15 kVA |

| AIR CONSUMPTION |

TO BE OBTAINED |

TO BE OBTAINED |