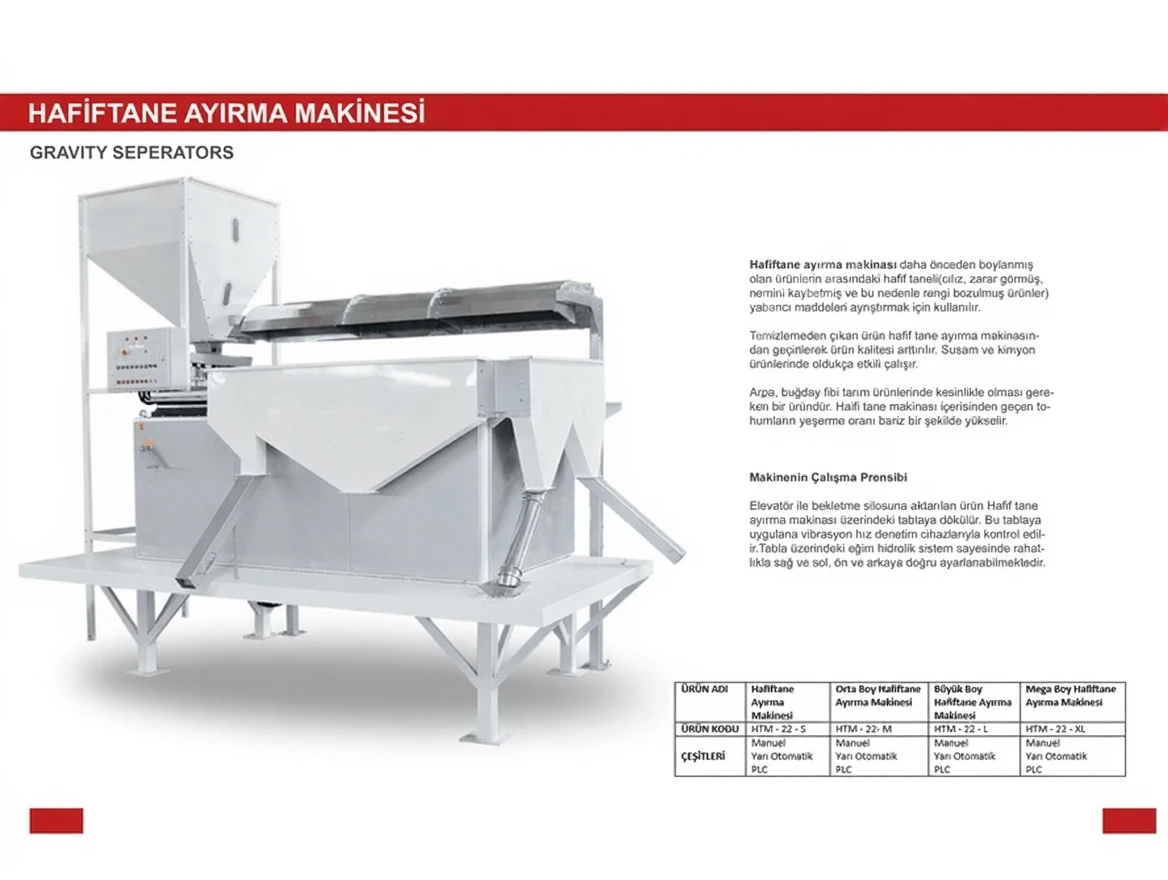

Light Grain Separator / Gravity Separator

| Brand | Dinamik Makine |

|---|---|

| Model Type |

HTM-22XL |

Light Grain Separator

Gravity Separator Sieving Machine

Gravity separations are used for the removal of impurities, admixture, insect damage, and immature kernels from the following examples: wheat, barley, oilseed rape, peas, beans, cocoa beans, linseed. They can be used to separate and standardize coffee beans, cocoa beans, peanuts, corn, peas, rice, wheat, sesame, and other food grains.

The gravity separator separates products of the same size but with differences in specific weight. It has a vibrating rectangular deck, which makes it easy for the product to travel a longer distance, ensuring improved quality of the end product. The pressurized air in the deck enables the material to split according to its specific weight.

As a result, the heavier particles travel to the higher level while the lighter particles travel to the lower level of the deck. It comes with easily adjustable air fans to control the volume of air distribution at different areas of the vibrating deck to meet the air supply needs of the deck. The table inclination, speed of eccentric motion, and the feed rate can be precisely adjusted to achieve smooth operation of the machine. One of the many advantages of the PLC Model is its clever memory system for machine parameter adjustments and less reliance on operator skills. Mechanic or Semi-Automated Models are also available in different sizes for different capacity needs.