Plastic PVC Pipe Profile Extrusion Machine

| Brand | Sarem |

|---|---|

| Model Type |

S-BE-001 |

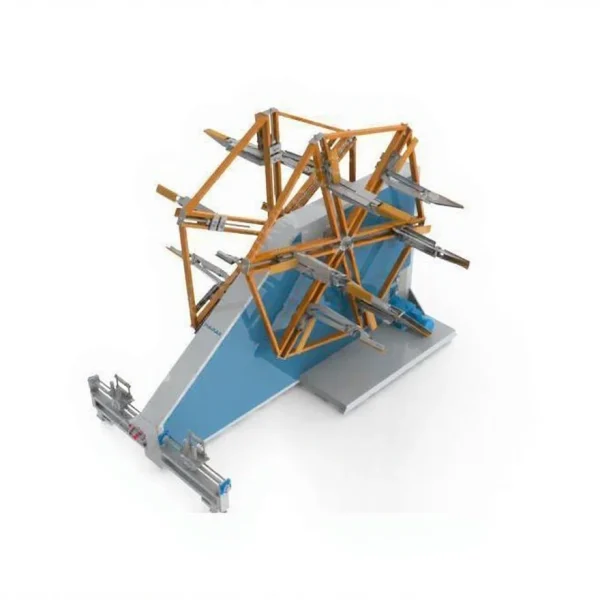

SAREM PP, PE and PVC PIPE EXTRUDER

Sarem Machine Extruders, produced in accordance with world standards with different torque and capacities of screws and barrels in the range of 20mm-150mm screw diameter, different transmission speeds, and of course, with the advantages of technical and cost-effectiveness and with SAREM MACHINE quality

With our fully automatic production lines, raw material savings can be maximized in pipe productions from 16mm to 1000mm in diameter. Lines suitable for standard pipe types or non-standard complex pipe production needs can be produced. Sarem Machine produces Parallel twin-screw extruders, Single-screw extruders, and co-extruders for PE, PP, and PVC high-performance straight pipe, composite pipe, and Corrugated pipe production lines.

The continuous development of machine technologies has enabled us to produce new Sarem extruders and these products are the result of all-time developments in extruder and screw technologies.

Sarem Machine has achieved the longest service life by providing optimum hardness and durability using German certified nitration steel [ PHONE HIDDEN ]CrAlNi7) material and gas nitration in the screw and barrel.

Sarem Machine has provided the highest revolution sensitivity by directly coupling Zambello brand reducers, used by world leaders, to the extruders.

Due to many different advantages, the frequency converter AC motors we use as a Sarem standard require a minimum maintenance service, do not require intensive maintenance with their brushless and brushless feature, provide significantly simpler use compared to DC motors, and provide an extra energy saving of 40%. Apart from the standard bearing lubrication, it does not require maintenance. Since they can be operated at lower speeds, the highest level of energy savings is achieved and noise pollution is significantly reduced.

Sarem extruders are specially designed for each PE, PP, and PVC straight and corrugated pipe production based on maximum performance, maximum efficiency, and longest service life principles.

All Sarem extruders are equipped with precise temperature control equipment as standard in the screw barrel, allowing adjustments for different raw materials and preventing variations in the output products.

The revolution sensitivity is provided at the most suitable level with the ABB brand used as driver. In this way, the highest efficiencies have been achieved at low cost.

The ceramic stones and wires used in our heaters are imported from Germany, thus the service life has been extended and the electricity consumption has been reduced to minimum levels.

World-renowned international brands such as Siemens, Telemecanique, Weidmüller, LG are used in the control panel. The longest service life is provided with our designs and climate control systems suitable for different climates.

According to the request of our customers, PLC touch screen or manual control systems from world-renowned brands can be installed.

Our machines, which combines with proven parts such as Zambello, Fuji, ABB, Siemens, LG in the main components, created by Turkish engineering, are equal to or superior in performance compared to German and Italian counterparts, and definitely much more affordable in price “

Related products

200 / 250 Kg Tek Burgu HDPE – LDPE Plastik Pvc Boru Extrüder

In stock

| Brand | Karakuş Makina |

|---|---|

| Model Type |

75/34 |