Polyester Fabric Warp Tension

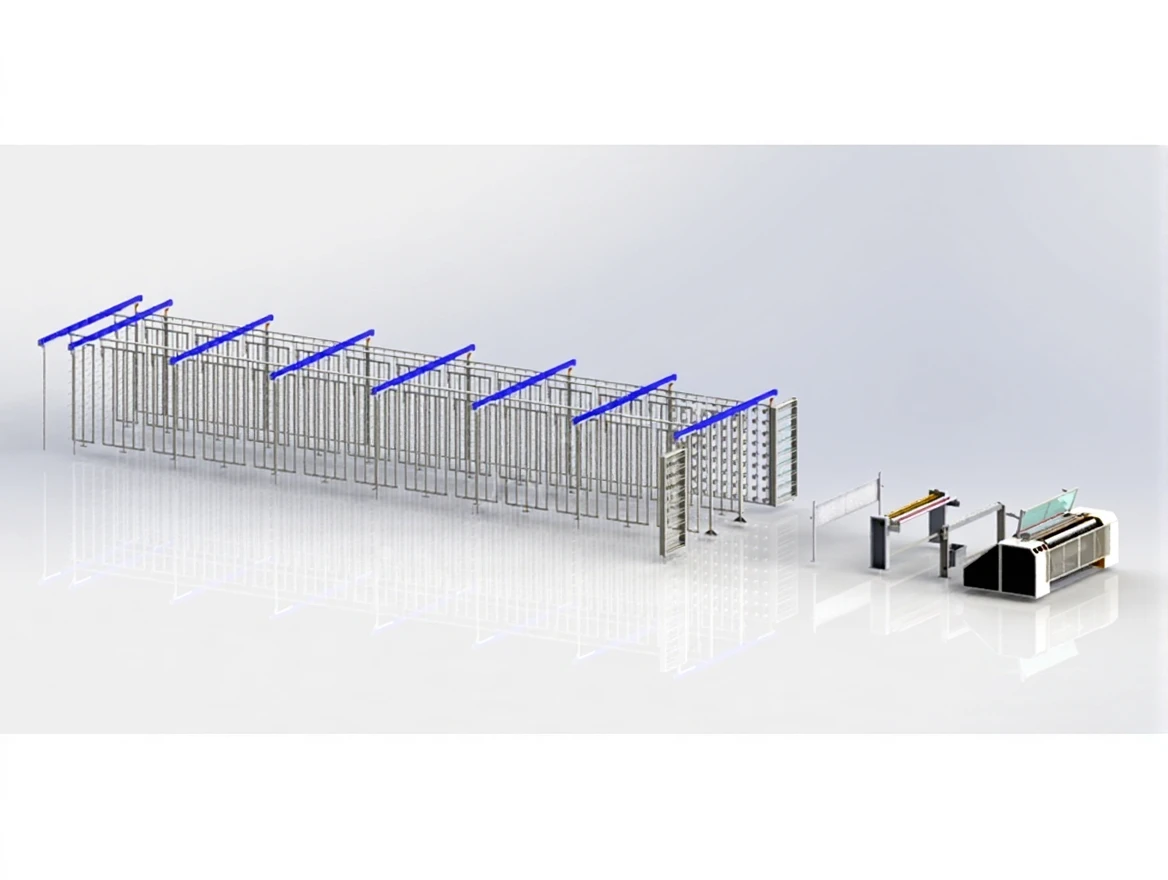

Kartaloğlu Machine Features

Machine Components

LEVENT LOADING / UNLOADING

The hydraulic drive levent lowering and lifting table positioned in the inner part of the warp machine allows for lowering and lifting according to the desired height.

BRAKE SYSTEM

There are a total of 4 separate brake mechanisms on the machine.

All brakes ensure the machine comes to an abrupt stop in cases of “Normal Stop – Emergency Stop – Rope Break – Completion of Desired Length”.

Tension Unit

Thanks to the tension unit positioned between the machine and the warp, the desired tension is created on the yarn, resulting in smooth winding.

WINDING FRAME

It protects the operator from dust and wind coming from the warp unit during operation.

Thanks to its movable feature with pneumatic piston drive, it automatically retracts when the machine stops, facilitating the operator’s intervention on the yarns.

Thanks to the stainless steel fixed pipe located at the bottom of the frame, it ensures that the yarns coming from the upper levels of the warp are at the same level as the lower yarns at the comb entrance.

ACCORDION COMB SYSTEM

It consists of 100 mm accordion (zig-zag) parts.

The comb opening – closing and right – left movements are driven by separate motors. Each of these operations can be easily performed with a single button.

OILING UNIT

Thanks to this unit positioned just before the guiding cylinder at the comb exit, the desired oil will be transferred to the yarn.

The oil in the tank is continuously circulated, and dirt coming from the yarn is filtered from inside the tank.

GUIDING CYLINDER

The cylinder is coated with ebonite.

This cylinder, which is very precise and durable, has been specially balanced dynamically and statically.

The machine speed and meter counting are done through this cylinder.

PLC / OPERATOR PANEL

All mechanical and electrical equipment systems on the machine are under PLC control.

There is a PLC and a touch screen.

There is an operator panel with a touch screen that allows control of all functions on the machine and is easy to use.

All materials on the panel are readily available in the market.

Related products

3600-1800 mm Table Type Photoelectric Fabric Quality Control Machine

In stock

| Brand | Açelya Makine |

|---|---|

| Model Type |

AYV5HLB |

Fabric Opening and Quality Control Machine from Car to Car

In stock

| Brand | Açelya Makine |

|---|---|

| Model Type |

TP3600 |