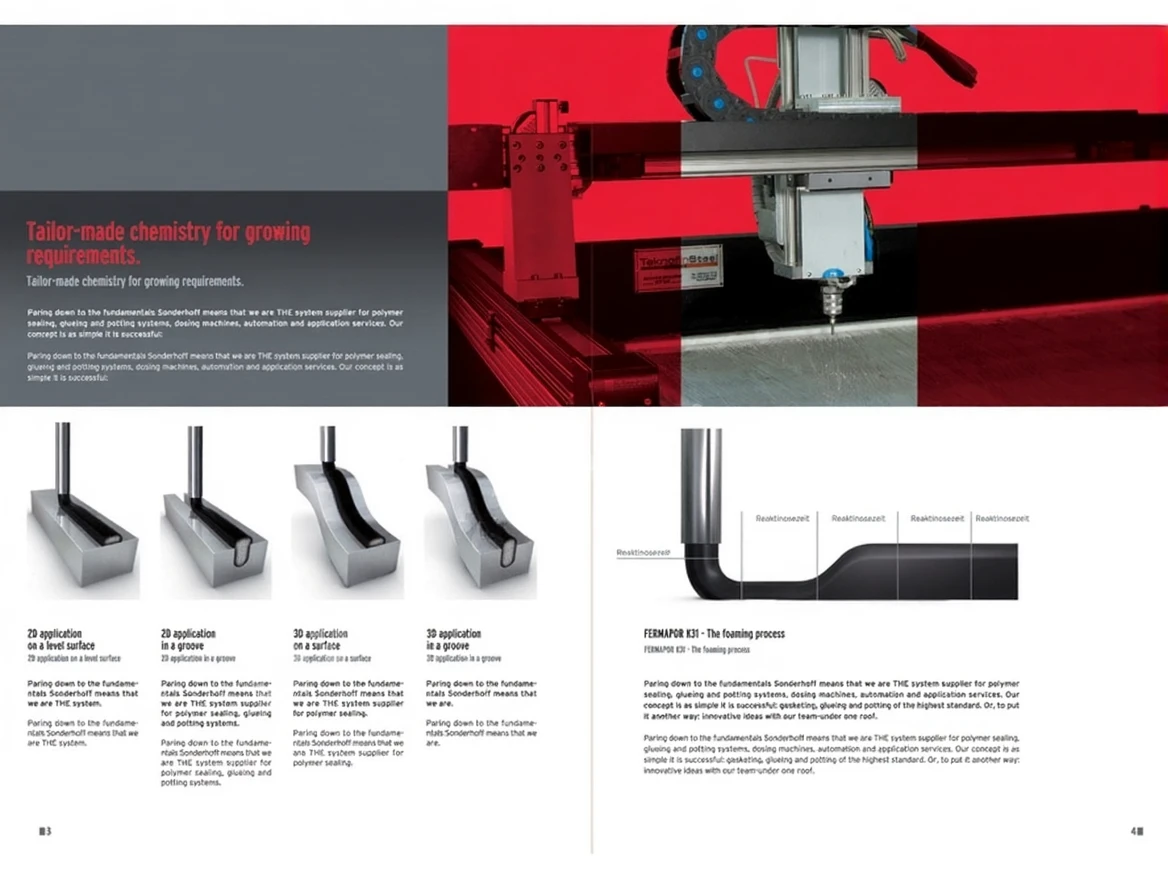

Polyurethane Liquid Gasket Pouring Machine

| Brand | Teknofinsteel |

|---|---|

| Model Type |

ROBOSİM 0735 |

Polyurethane Liquid Gasket Casting Machine, Teknofinsteel, Pu Gasket Sealing Machine

Rubber foam gasket sealing Machine

Pu sealing Machine gasket Machine

Pu gasket dispensing Machine

Polyurethane gasket seal Machine

Pu gasket sealing Machine

Pugasketing Machine

Pu polyurethane foam sealing

Best pu gasket sealing Machine

Automatic sealing foam

Product Features:

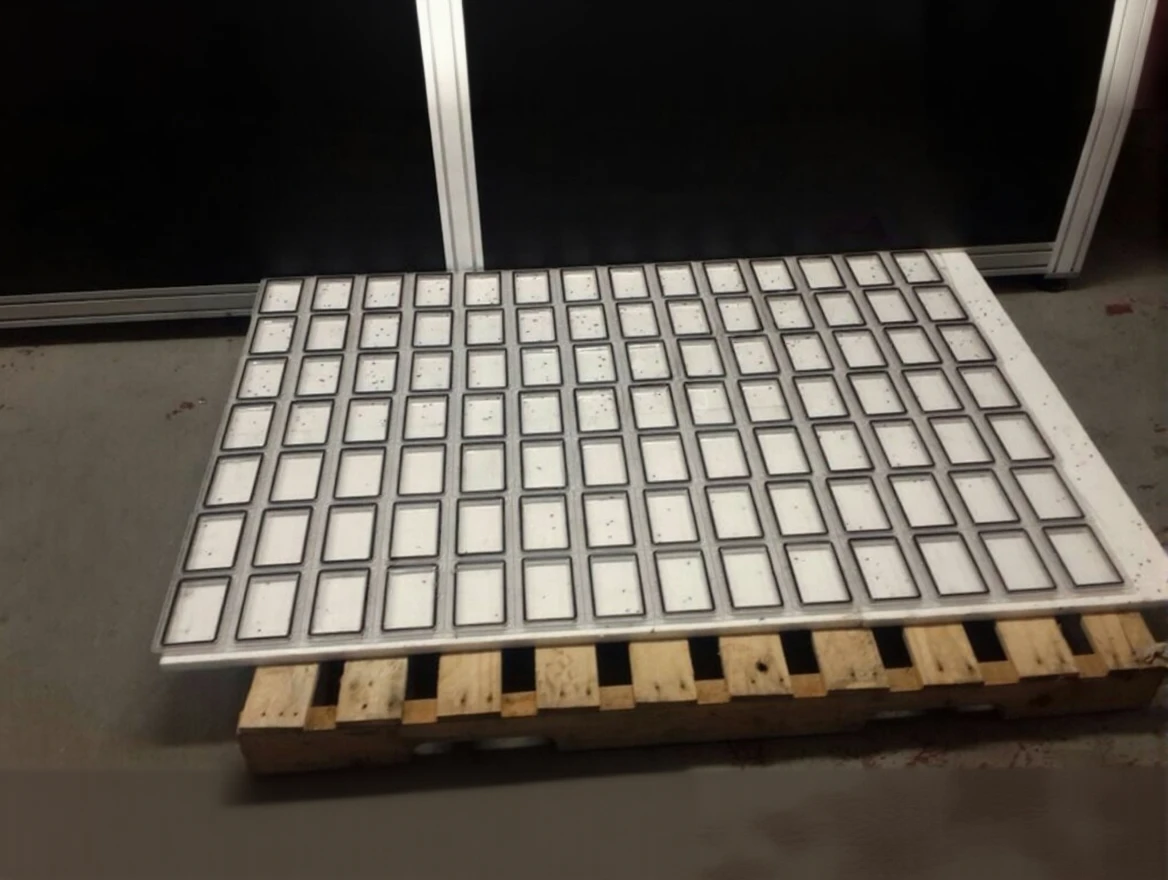

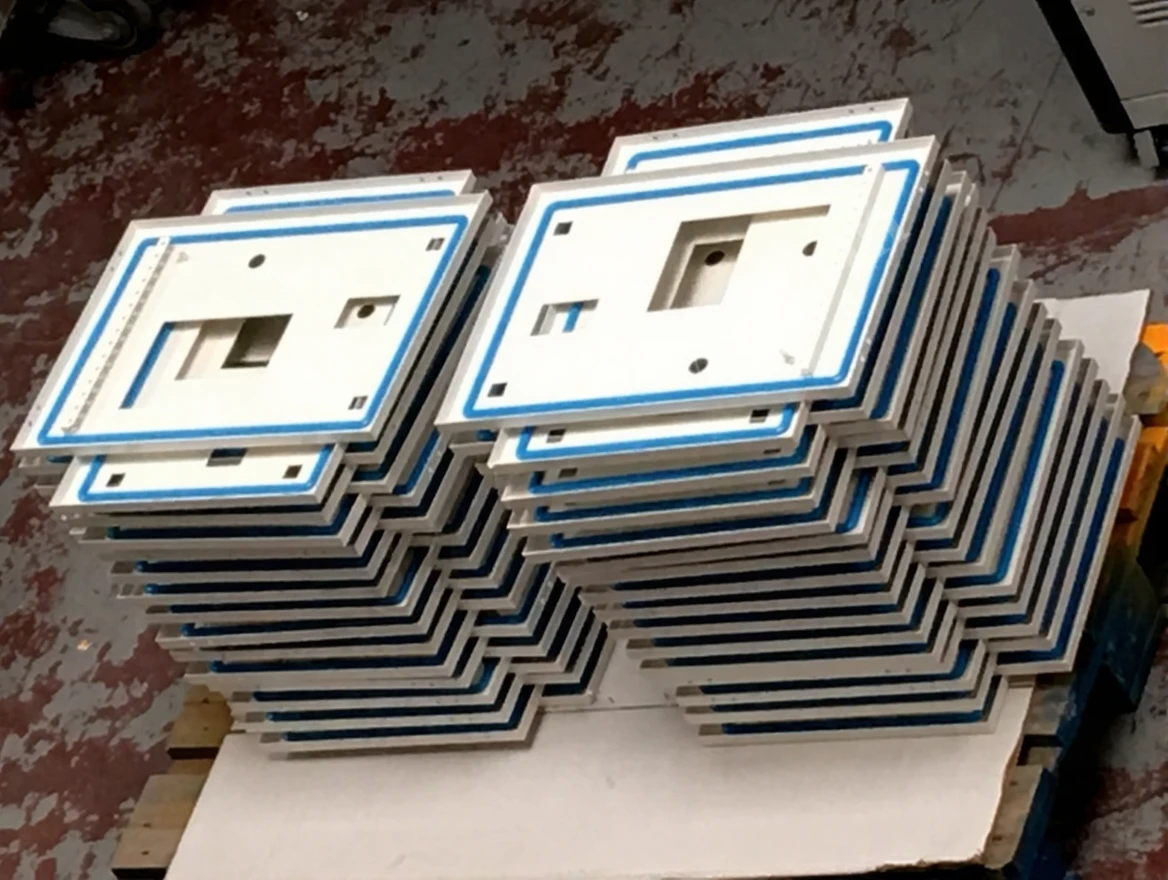

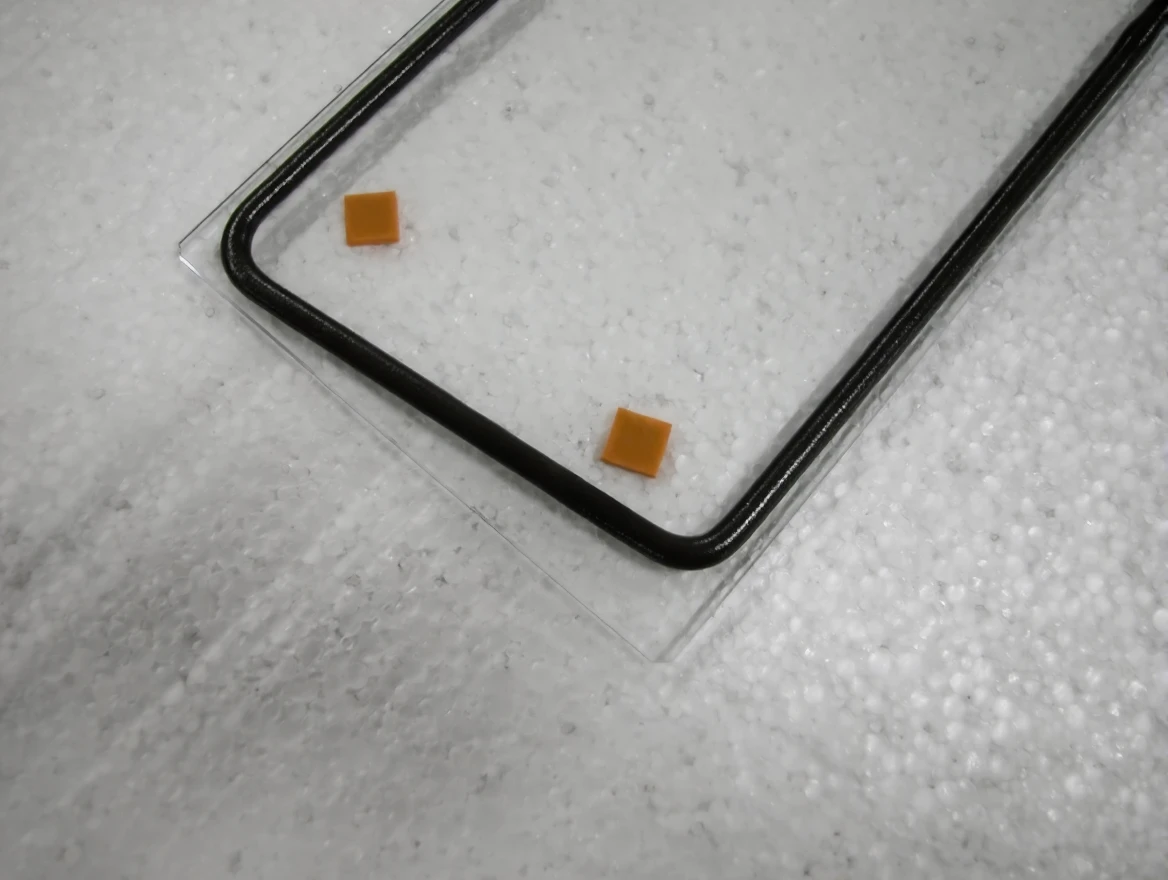

1. Heat, Sound, Dust and Liquid protection (IP55/65/68)

2. Practical and very easy application, liquid pu

3.Electrical enclosure, rack cabinet, air conditioning and cooling systems, lighting devices, clean room partition joining systems, developed on a cnc system with a three and four-axis polyurethane gasket casting machine for contract gasket casting system. The machine system; It has a wide range of use in different design lines. It has high configuration and compatibility between domestic and imported polyurethane raw material. Our machines are manufactured in two different models according to IP standards (IP54 – IP 65 ~ 68). PU gasket width is 1-10 mm, the width of the other is 5-30 mm. The customer can choose the model according to the product requirement or, if the width is beyond this strip, the machine can be designed according to the customer’s products. For more information: [ URL HIDDEN ]

4. Electrical enclosure Sealing With PU Gasket Foaming Machine

3. Does not deform when compressed for a long time, 20 years

4. High resistance to abrasion

5. Resistant to ultraviolet rays. Does not crack, does not tarnish

6. Withstands +80°C and -40°C temperatures

7. Does not slip, break when applied in place

8. Can be used in open and closed areas, electrical panel, rack cabinet lighting devices, UL certified paint buckets, automotive and white goods,

9. Dirt-repellent. Does not produce bacteria, does not decay, does not cause odor

Specifications

Robosim 0735 Polyurethane Sealing Machine is designed to cast liquid seal to the electrical panels

Robosim 0735 model dosing and mixing unit with two components.

* Sealing Machine with Double Drawers

* X-2400mm Y-1200mm Z-350mm

* Siemens CNC Programme

* Bosch rexroth Aluminium Construction

* Servo Motor (Siemens)

* Drivers (Siemens)

* Gear Pumps for dosing

* Tanks with double chrome wall

* Cooling Device

* Chrome mix head

* Control Panel

* Motor Gear Box

* Automatic Cleaning and Drying System

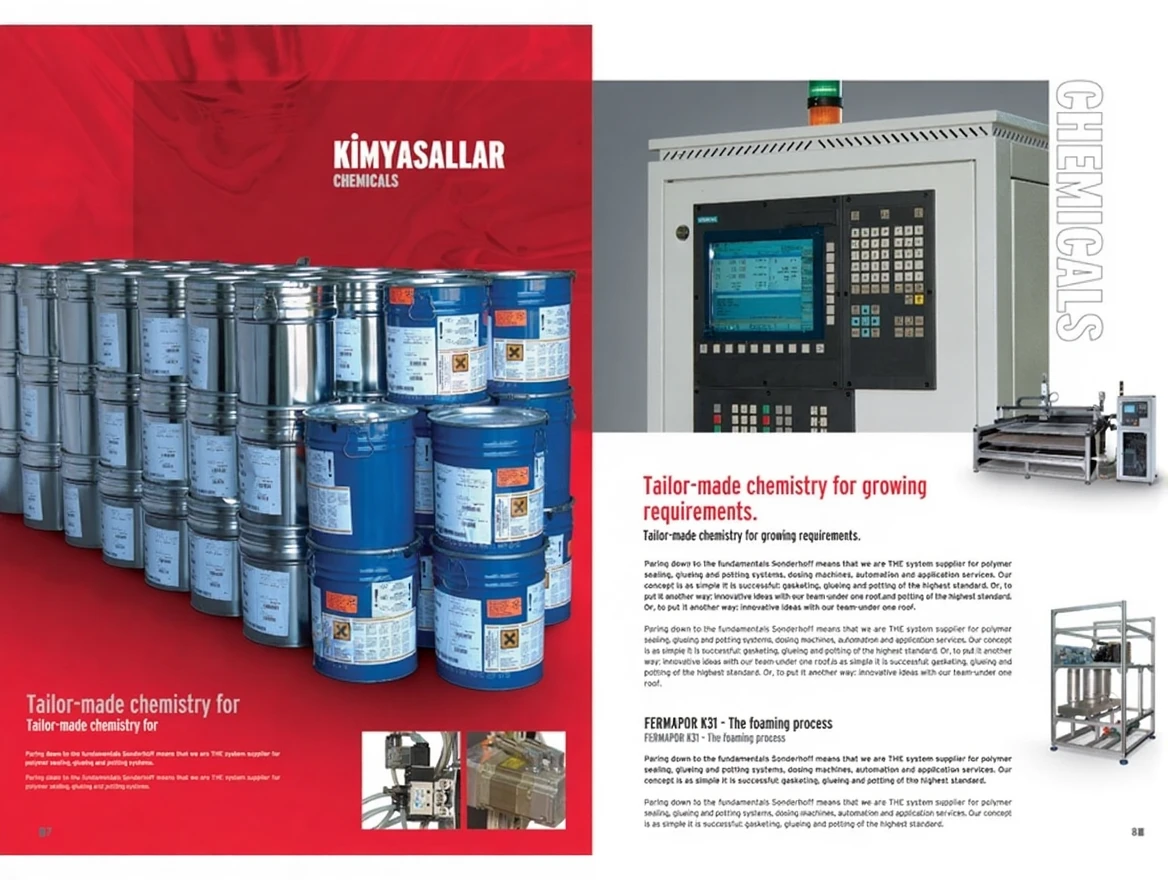

* 30 Liters Chrome Solvent Tank, 75 liters Polyol Tank, 75 liters isocyonate tank

* Dropping Valve

* Installation and Training (Start up)

* 3 years guarantee for spare parts

* Mixing head (With Servo motor)

* Air Dryer

* Air Filter

* Dosing pumps

* Mixer with reducer ( For the polyol)

* Air Regulator

* Mixer and tank cooler

* Chiller unit

* Pneumatic infrastructure

* Sealing Chemical fixtures

* Chrome-nickel cleaning system

Related products

1000-6000 Gr/Sec High Pressure Polyurethane Injection And Dosing Machine

In stock

| Brand | Polymix |

|---|---|

| Model Type |

P-PM010 |

1000-7000 Gr/Sec High Pressure Polyurethane Injection And Dosing Machine

In stock

| Brand | Polymix |

|---|---|

| Model Type |

P-PM011 |

40-50 Pieces/Minute Ventilation Clip Assembly Machine (Horizontal Type)

In stock

| Brand | Parola Makina |

|---|---|

| Model Type |

PM-HKO-V.01 |

Thyristor Controlled Transformer Type Air Cooled Coating Rectifier

In stock

| Brand | Redartı |

|---|---|

| Model Type |

R-KR-006 |