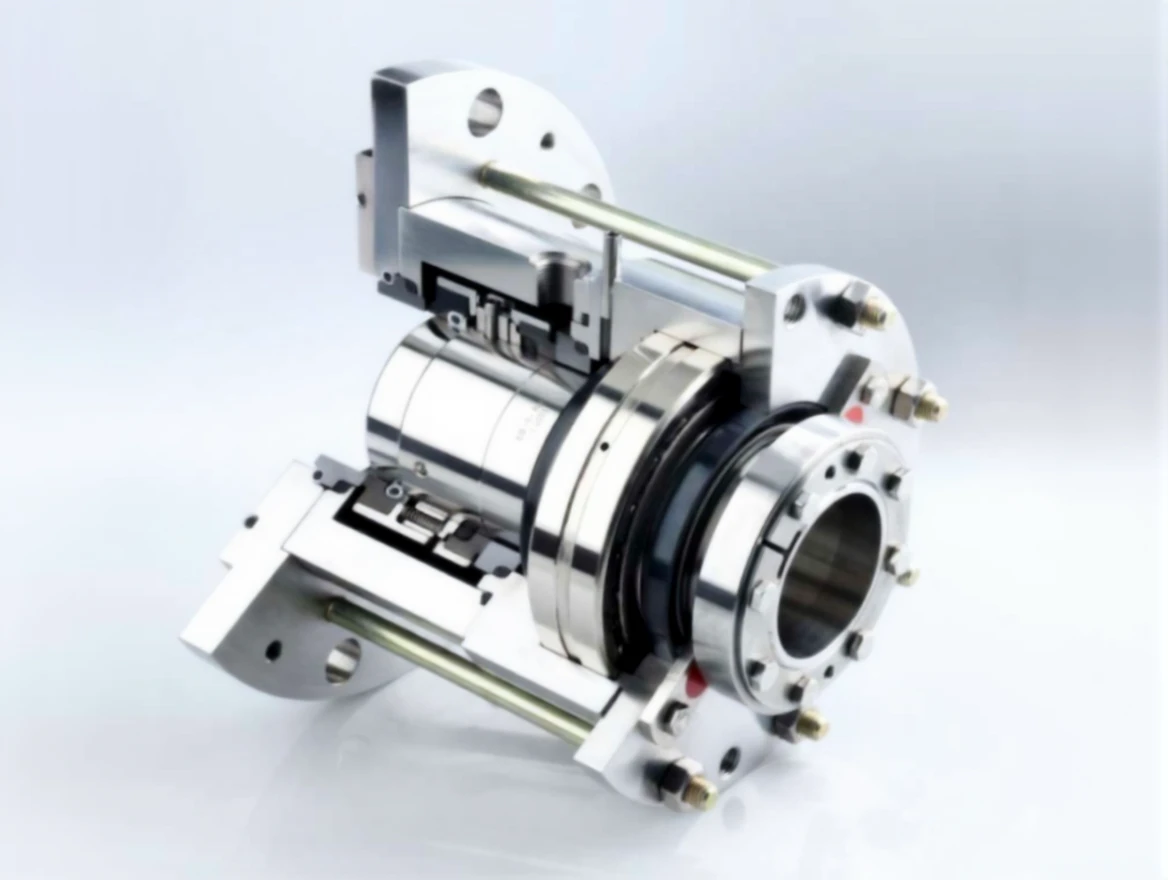

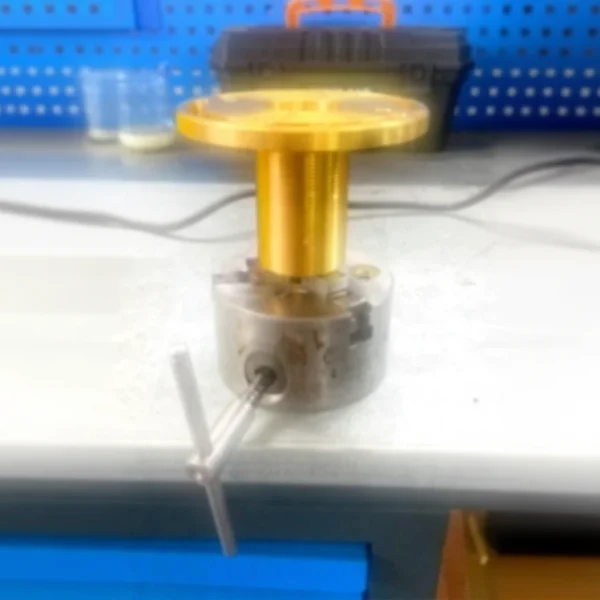

Reactor Boiler Seal Part Manufacturing

| Brand | Unimek |

|---|---|

| Model Type |

UNMK-MP8 |

Unimek UNMK-MP8 Reactor Boiler Seal Part Manufacturing

It is a critical component to ensure a safe working environment in industrial systems operating under high temperature and pressure conditions. In the chemical, petrochemical and energy industries, these parts prevent the leakage of liquids or gases while ensuring that equipment operates efficiently and safely. Reactor boilers are systems where liquids and gases are transported under high pressure and temperature changes are constantly experienced. Therefore, the packing must provide high durability, chemical resistance and sealing performance. The packing part must not only seal, but also be resistant to influences such as vibrations and temperature changes.

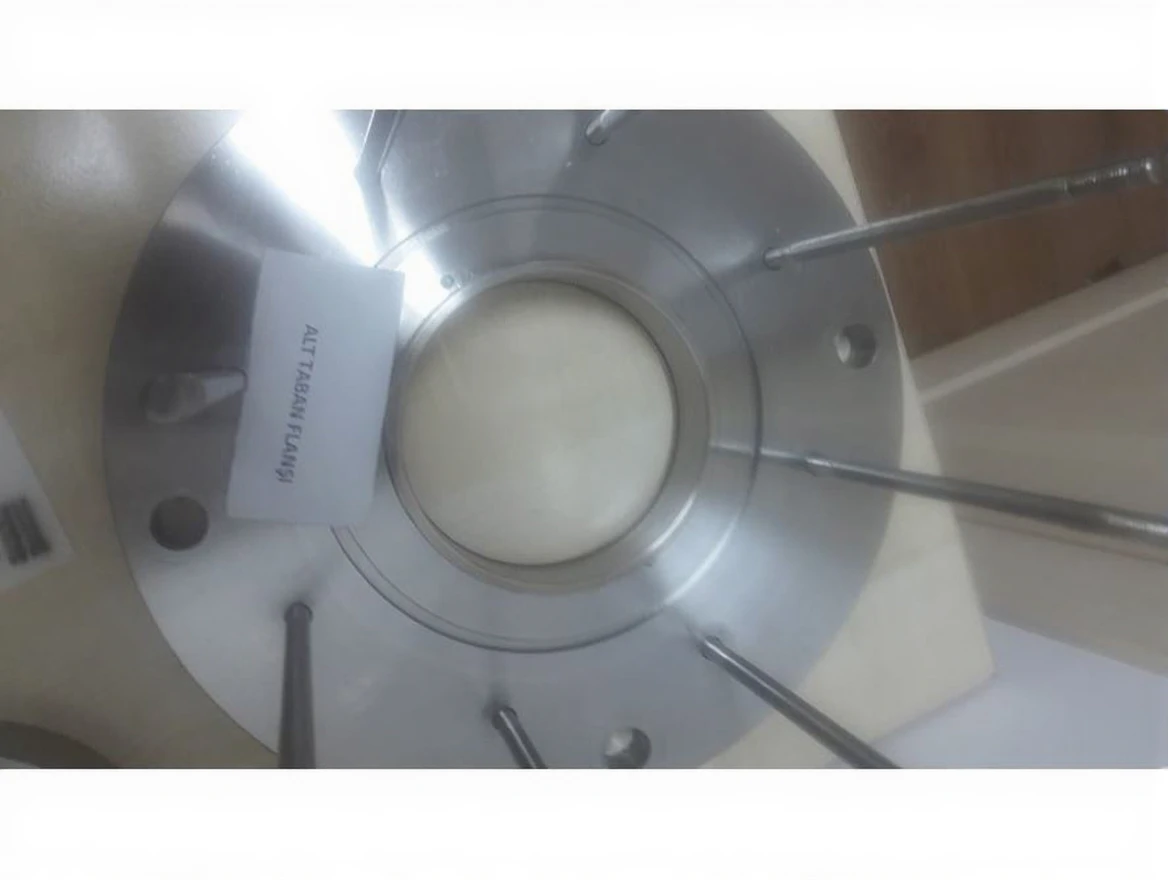

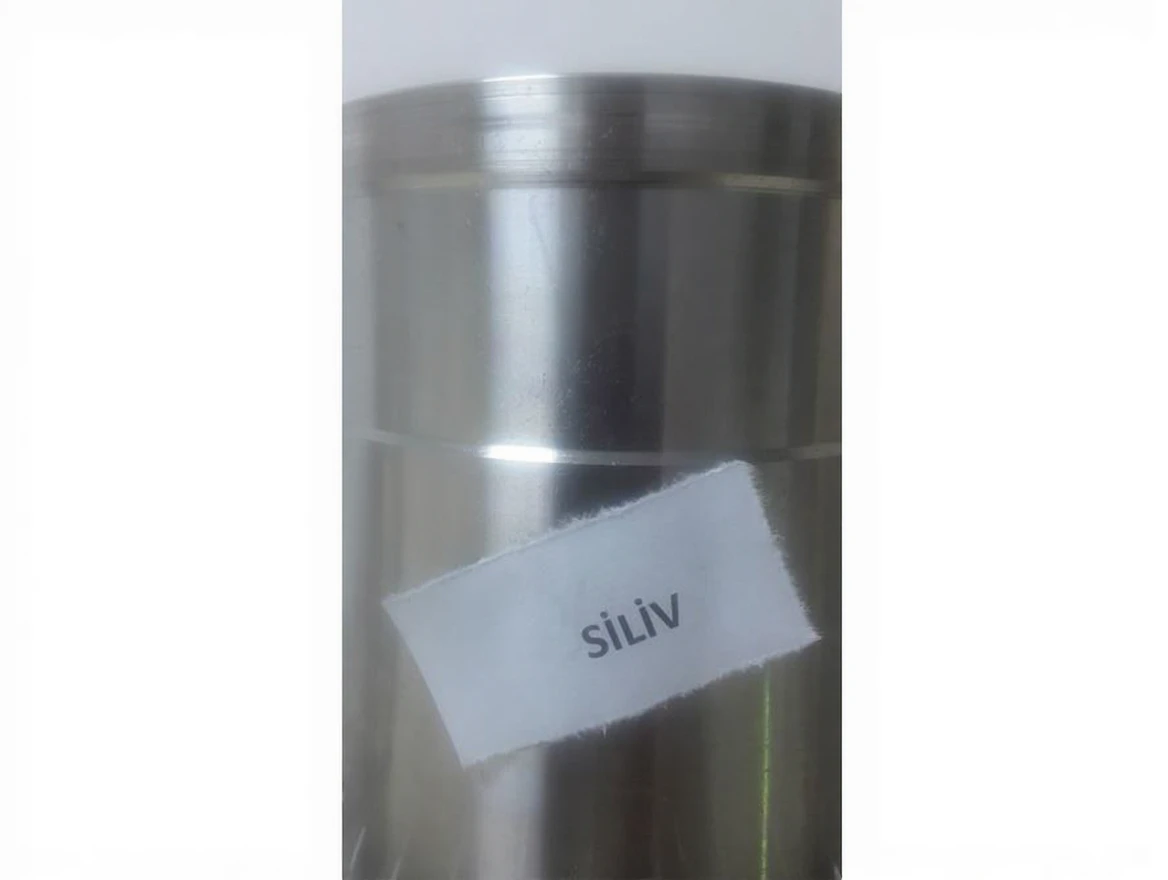

The reactor boiler seal manufacturing process consists of various steps, starting from the design phase to prototype production and quality tests. First, engineering drawings and calculations are made to ensure that the design operates safely in extreme conditions such as high temperature and pressure. During prototype production, the design is subjected to functional tests. In the selection of raw materials, high-performance materials such as stainless steel, elastomers or PTFE are often used. The manufacturing process includes CNC machining, die-casting methods and assembly. Parts are checked through tightness tests to verify that each component performs its correct function. Surface treatments are carried out to increase the durability of the material and protect it against corrosion.

The most important features of these seal parts include high durability, chemical resistance and excellent sealing performance. Produced using materials that can withstand high pressure and temperature conditions, these parts offer long-lasting use. Sealing performance is especially critical in preventing liquids in reactors from leaking out. Additionally, these seal parts are easy to install and very simple to replace when necessary, which speeds up maintenance processes. It is an ideal solution for use in sterilization and high-pressure reactors in the food, pharmaceutical, chemical and energy sectors. The robustness of the seal parts increases the safety of industrial systems and increases operational efficiency.

Related products

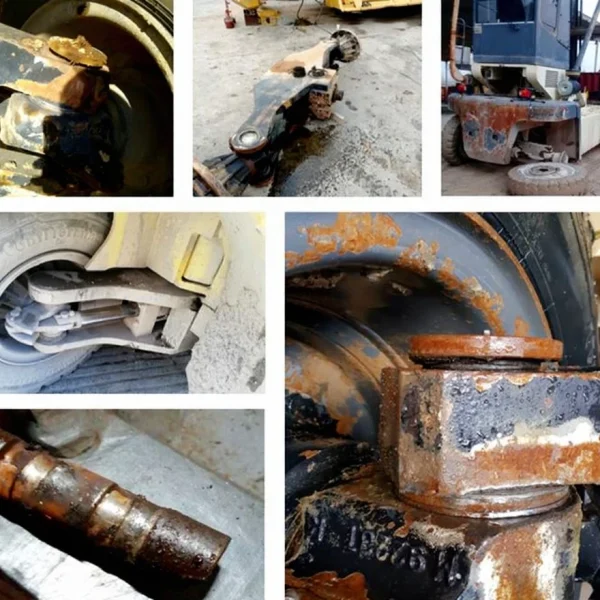

Axon King Pin Overhaul and Contract Machining Services

In stock

| Brand | Hydro Works |

|---|---|

| Model Type |

H-FT-001 |