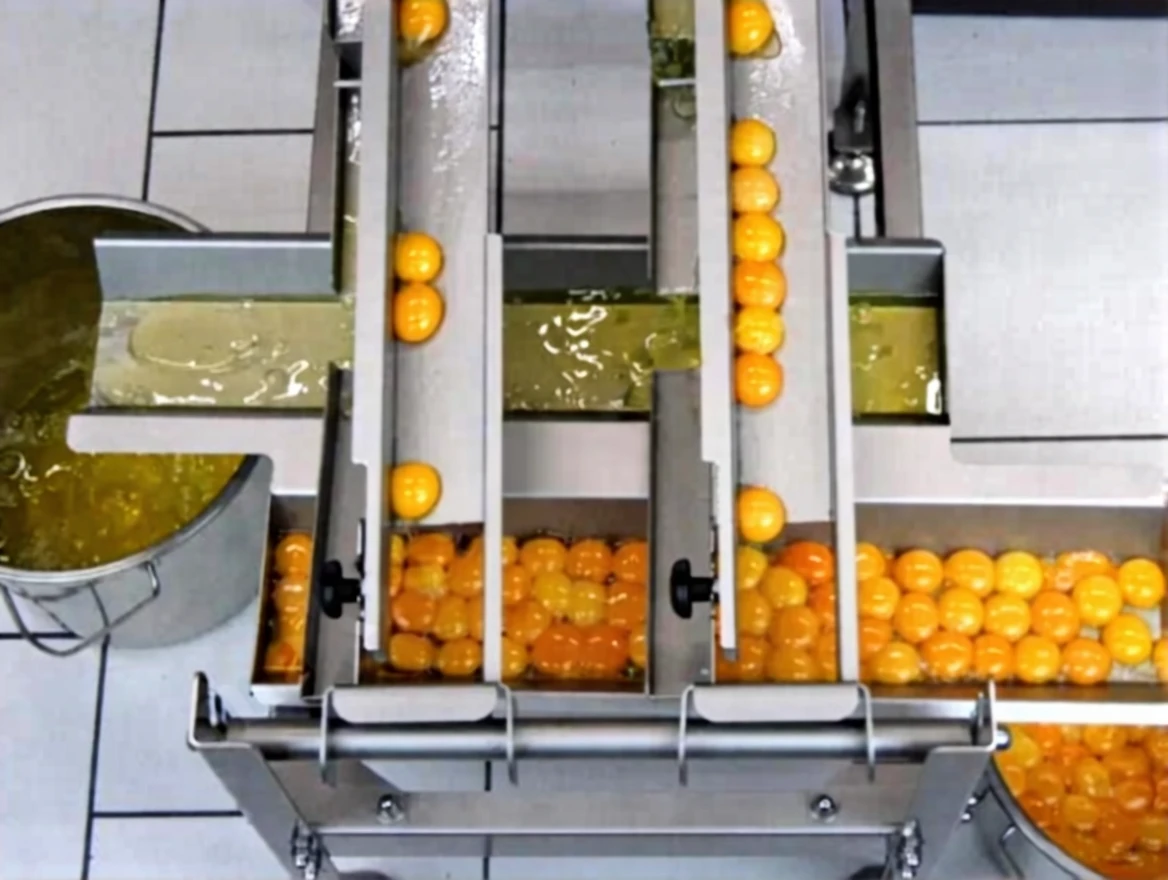

9600 Units / Hour Egg Breaking and Separating Machine

RX2 Various Functions: The egg breaking and separating machine RX2 can be used to obtain fresh liquid eggs. Additionally, it can separate eggs into components such as egg yolk and egg white if desired.

Adjustment Capability: The height and impact force of the shell breaker blades can be adjusted on the machine. This feature makes it easier to break eggs with weak shells.

High Capacity: It has a maximum capacity of 9,600 eggs per hour, making it suitable for large-scale operations.

Automatic Feeding: Eggs are manually placed into the feeding compartment, and the machine automatically takes the eggs and performs the breaking and separating processes.

Ease of Use: The machine is simple and easy to use, reducing the need for staff training.

Different Operating Modes: It has two separate operating modes: delicate mode and fast mode. These modes are designed for eggs of different qualities, and the machine speed can be adjusted as needed.

Human Hand Imitating System: The egg shells are cracked and opened using special blades, ensuring the obtained eggs meet high hygiene standards.

Observer Operator: Any broken egg shells or cracked eggs detected by the machine can easily be directed to the discharge channel.

Stainless Steel Material: All parts in contact with the eggs are made of stainless steel, ensuring hygiene standards are met.

The RX2 egg breaking and separating machine is preferred by medium and large-scale egg processing plants, bakeries, pasta manufacturers, poultry farms, and bakeries. It increases both productivity and ensures hygiene standards, optimizing product quality.