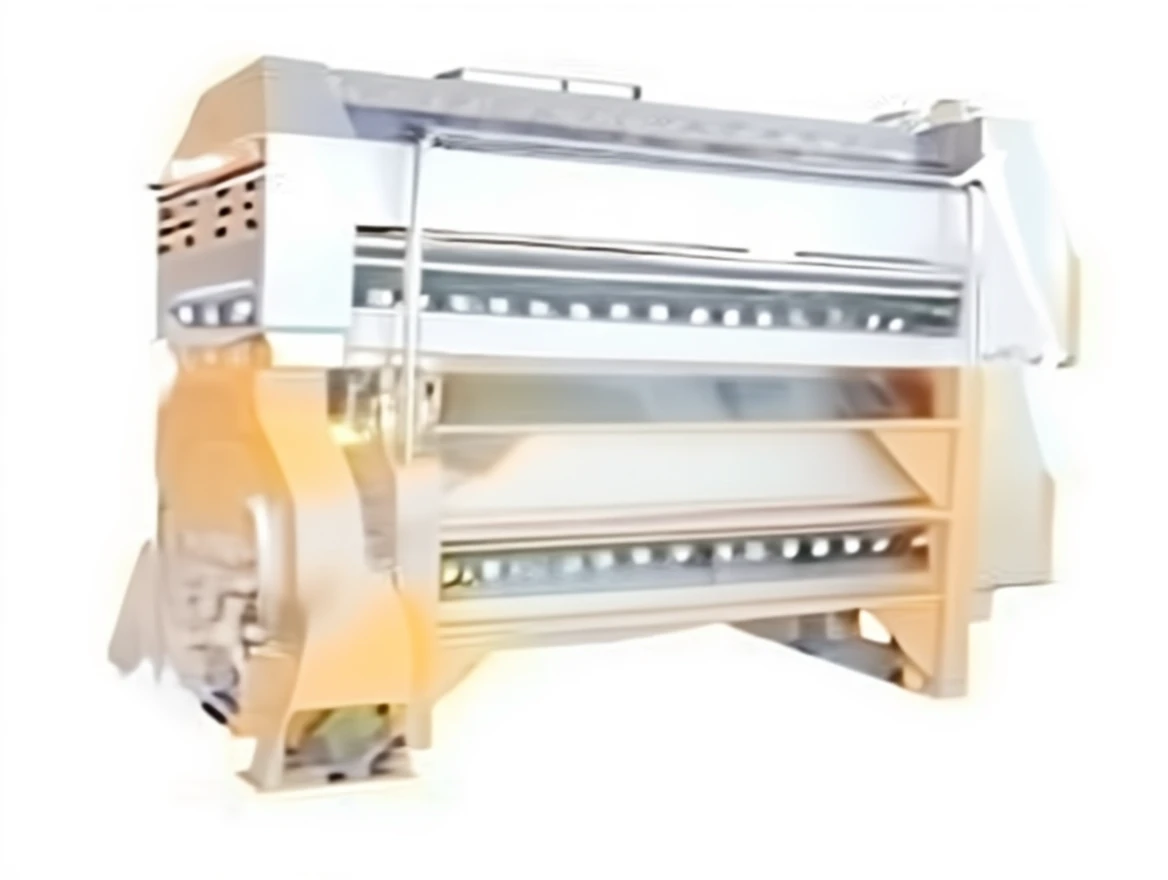

Semolina Sifter Machine / Stone Stone Mid-Heat

| Brand | Or-Taş |

|---|---|

| Model Type |

ORT-ISI |

Semolina sifters are used in flour and semolina factories to clean and classify semolina mixed with flour coming from sieves. The working system consists of 2 vibro motors and 1 aspirator. The product, the flow rate of which can be adjusted, is evenly distributed onto the screens inside through a curtain. The screening process is carried out with 2 or 3 layers of screens. The machine is powered by a vibro motor. An equal vacuum is created on the entire surface of the sieves with an aerodynamic air duct and air adjustment dampers. Products with expanded surface areas such as bran are held by vacuum, separated from the product and sucked through the aspiration connection with air suction. The bran-free product (semolina) is classified according to the size of the grains through the screens. The desired air is adjusted through the air dampers in the machine. The most important aspect of semolina sifters is to have sufficient air and to adjust the angles of the vibro motors correctly. Without these adjustments, the material will not be sifted.