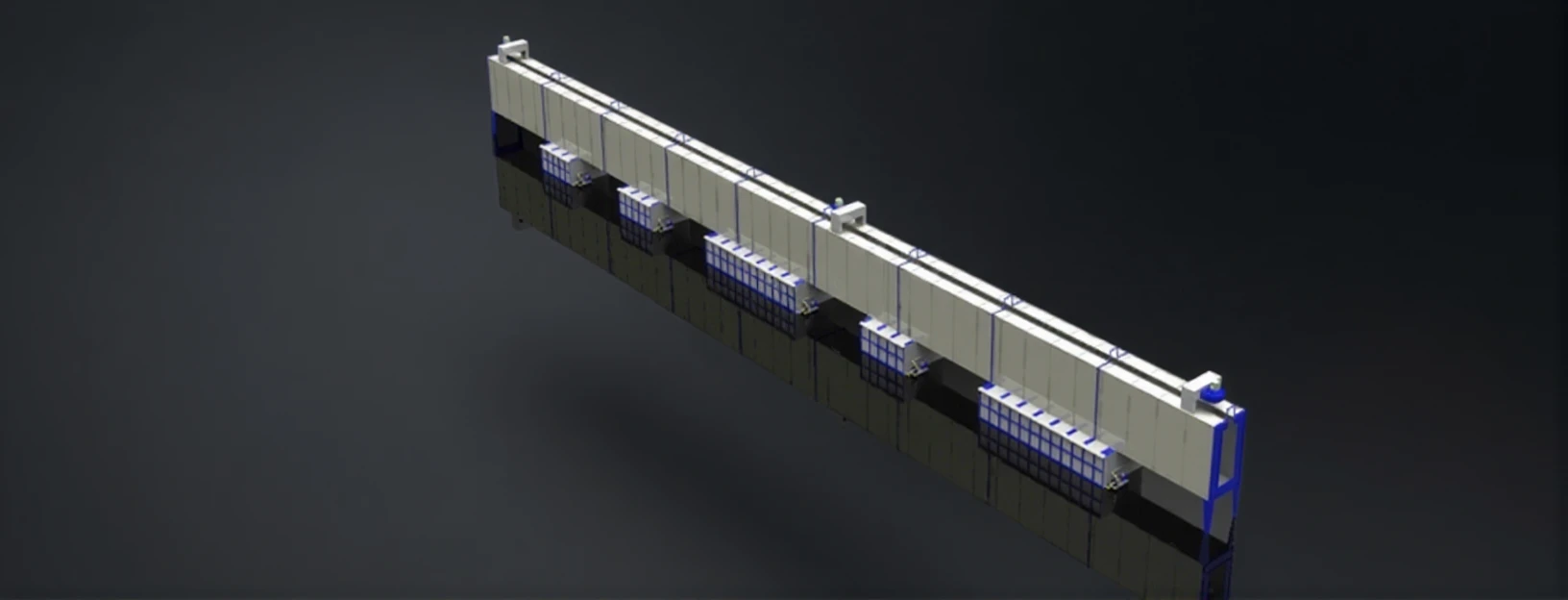

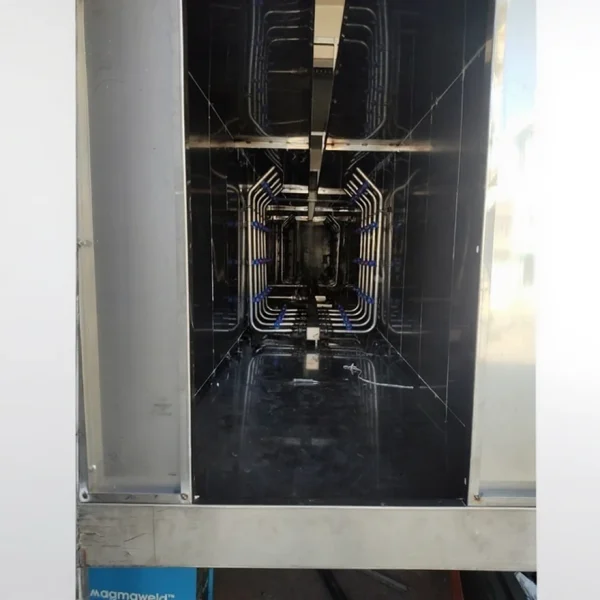

Spray Zinc Phosphate Plants

It is the most modern pre-painting phosphating method in today’s technologies. Iron Phosphate application applied before electrostatic powder paint or wet paint uses pressure in addition to chemical power, concentration and temperature. Although the initial investment cost of this process is high, it is preferred by various sectors due to its coating quality, speed and less chemical use. Two separate degreasing and phosphating methods are applied in the Painting Spray Zinc Phosphate process. The first is Alkaline degreasing and the second is Neutral degreasing. In alkaline degreasing, iron phosphate and degreasing are installed in separate boilers, and in neutral degreasing, iron phosphate and degreasing are installed in the same boilers. It has less installation and investment costs than the first method, but the coating quality is lower.

The parameters to be considered in the Iron Phosphate process are as follows.

Related products

Rotary Basket Washing Machines With Shock Absorber Manuel Opening

In stock

| Brand | Wespy |

|---|---|

| Model Type |

DS-1250 |