Volde | Freebag Big Bag Unloading System

| Brand | Volde |

|---|---|

| Model Type |

Freebag |

Category: Other Manufacturing Machinery

Description

Big Bag Discharge

Big Bag Discharge Systems are used for the dust-free discharge and dosing of all kinds of powdered and granular materials from big bags. The big bag discharge system can also be used for filling purposes by mounting it on top of silos, bunkers, or mixers when a screw conveyor, rotary valve (cell wheel), or sliding valve is used at the outlet for precise dosing purposes. Thanks to its modular system, it is manufactured suitable for all kinds of options, providing a wide range of use and application area.

The big bag to be discharged is brought next to the system with the help of a forklift. With the crane on it, the big bag chassis is placed inside the system. Connection to the closed mouth unit inside the system is made by attaching the discharge skirt, ensuring dust-free and leak-proof discharge. After the connection is made, the skirt's rope is untied and the flow starts. At this time, the tension in the system is released, allowing the skirt to become independent for a comfortable flow. The pneumatic damper system, which is necessary for materials that are difficult to flow, is activated to ensure a smooth flow and complete emptying of the bag.

Advantages of the System

-

Big bags in various sizes can be used.

-

Weighing can be done using the negative weighing method with load cells.

-

Dust-free discharge is provided with the double-walled closed mouth unit.

-

It can be easily operated by one person.

-

Ensures smooth and complete discharge in materials that are difficult to flow.

-

It is modular and does not take up much space.

-

It keeps work safety at maximum level.

Bigbag Pneumatic Conveying

Dust raw materials can be introduced into production through various methods from the Big Bag Discharge Unit. In systems designed according to the physical properties of the material as well as the characteristics of the process, screw conveyor, vacuum conveying, or dense-phase pneumatic transport with blower blowing method can be used.

Related products

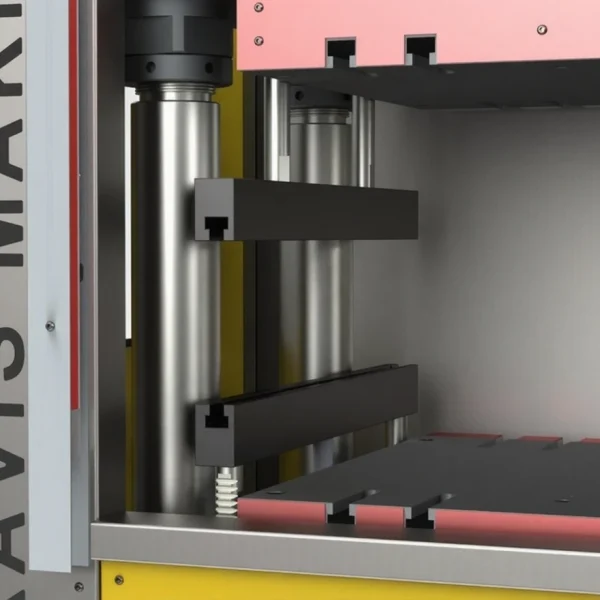

500Ton Rubber Press / Rubber Compression Press / Rubber Baking Press / Transfer Press 2Rt/3Rt/4Rt

In stock

| Brand | Kavis |

|---|---|

| Model Type |

Prs / K-500 |

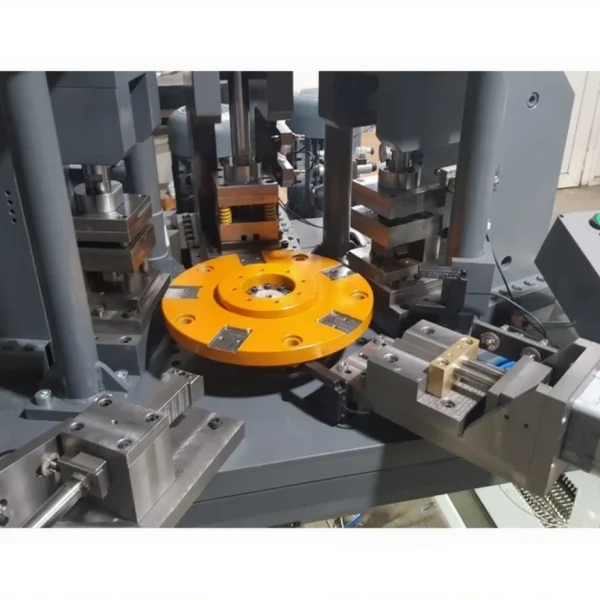

Fully Automatic Feed Cable Shoe Manufacturing Machine

In stock

| Brand | Yılmazoğlu Makina |

|---|---|

| Model Type |

Y-PE001 |