Volde | Fullbag Big Bag Filling Systems

| Brand | Volde |

|---|---|

| Model Type |

Fullbag |

Big Bag Filling

Big Bag Filling System

| The Big Bag filling machine allows the filling of powder or granular materials into big bag sacks with filling necks. Depending on the application, the material can be fed with various equipment such as slide gate valve, rotary valve, screw feeder, vacuum cyclone, etc. When the filling process starts, the material is poured into the bag and weighed simultaneously. When the entered filling value is reached from the control system, the material flow stops automatically. At the end of the filling process, the hook holders release the hooks, the operator starts the filling conveyor by pressing a button after removing the big bag neck from the filling mouth. The filled big bag moves on the conveyor towards the exit conveyor.

Big Bag Filling Features

Filling Capacity: Ranges from 500 kg to 2000 kg per bag.

Feeding Systems: May include screw feeding, pneumatic conveying, or belt feeding systems.

Filling Speed: Can fill between 5 to 50 bags per hour depending on the model and material.

Filling Accuracy: Accuracy of ±0.5% can be achieved.

Material Compatibility: Designed for various materials from fine powders to coarse granules.

Dust Control: Equipped with advanced systems for dust suction and retention.

Vibration Systems: Included to assist material settling and maximize bag capacity.

Automation: Modern machines include PLC controls, touch screen interfaces, and integrated software.

Installation and Services

Related products

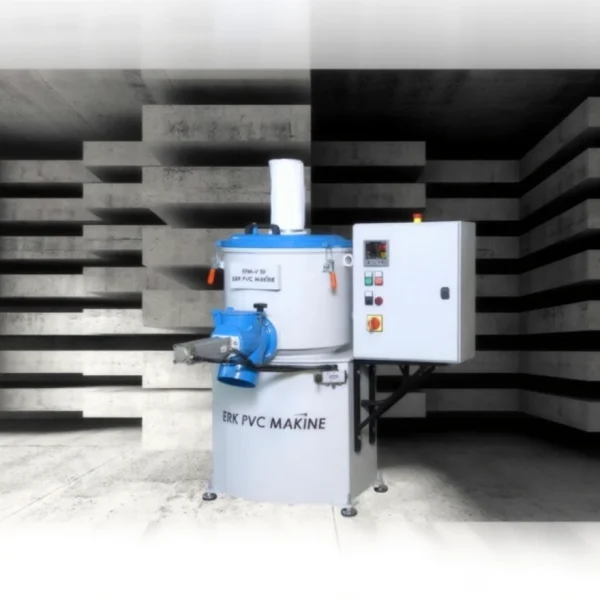

300 Kg Horizontal Turbo PVC Mixer – Heated Raw Material Mixing Machine

In stock

| Brand | Erk Pvc Makine |

|---|---|

| Model Type |

EPM-H300 FV / SS |