Bulgur Factory Automation Systems

| Brand | Endüstriyel |

|---|---|

| Model Type |

E-EOY-004 |

Category: Automation Systems

Description

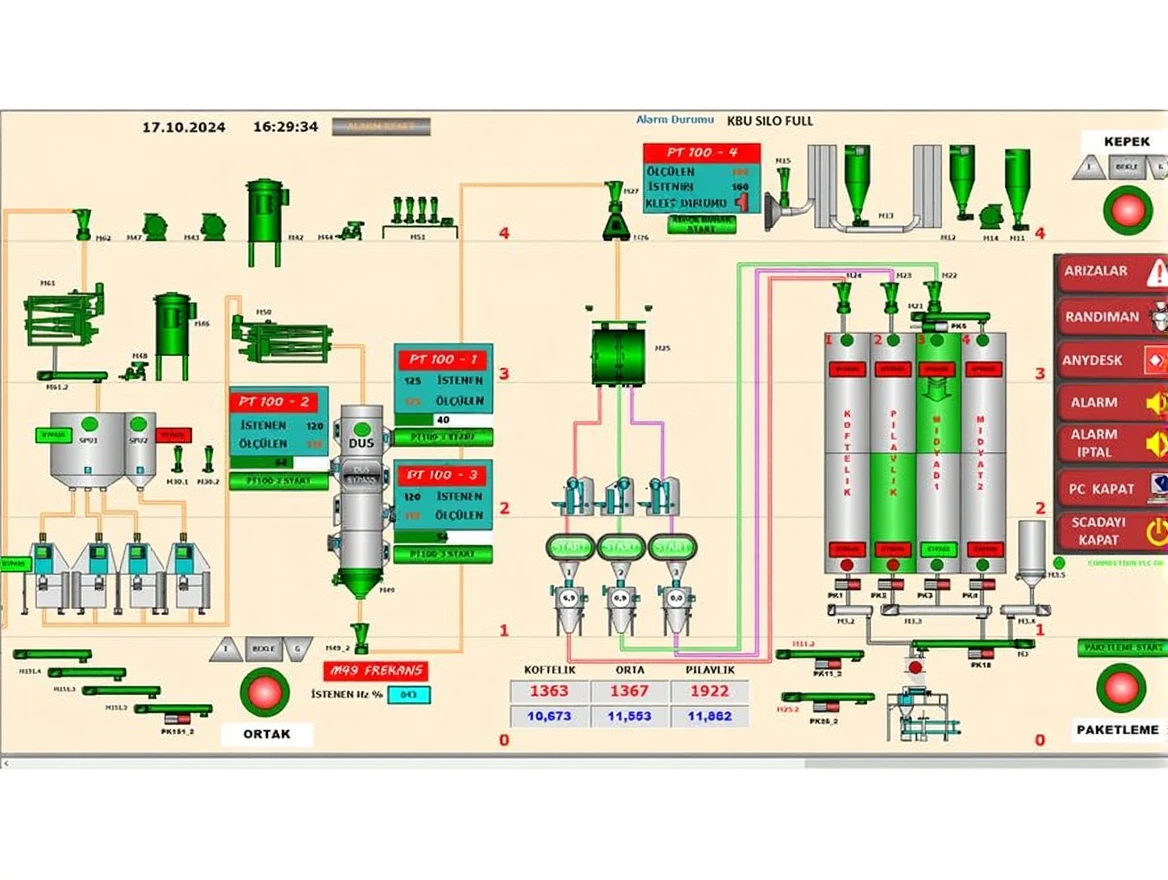

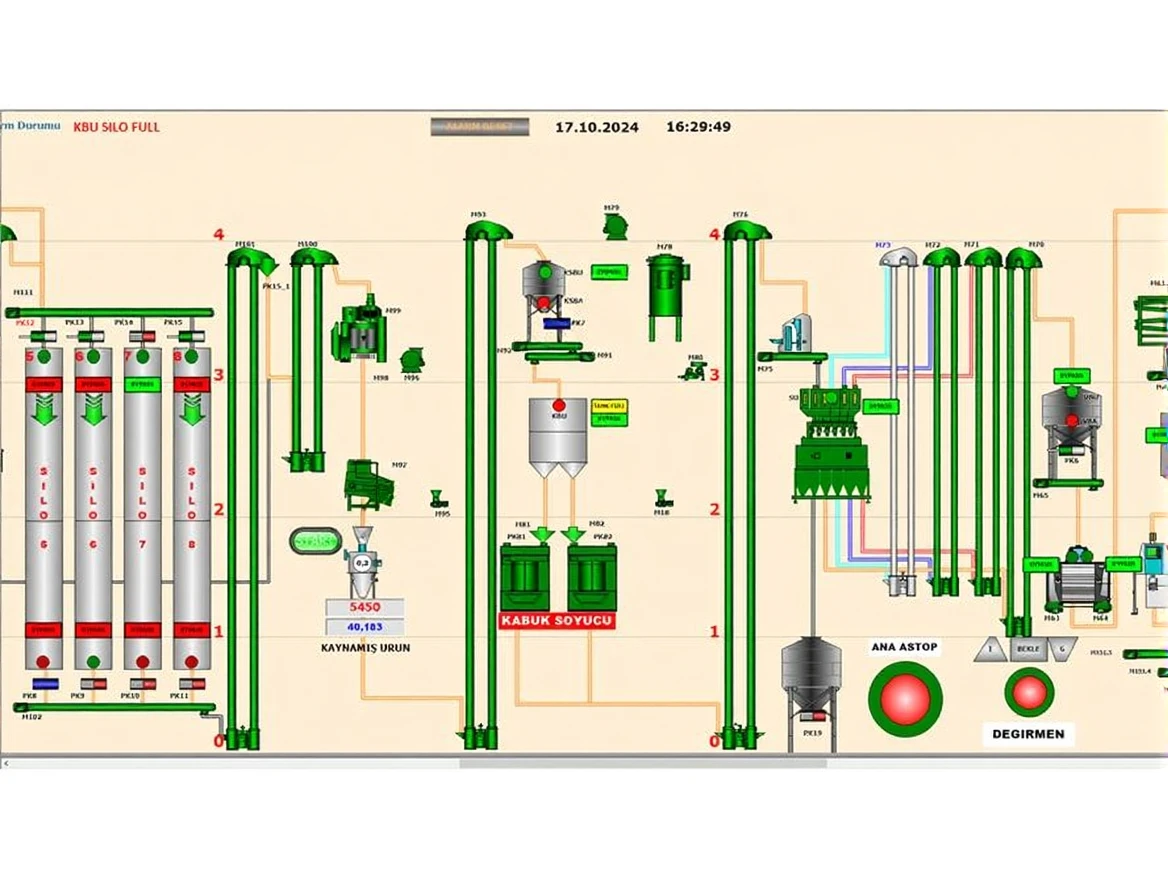

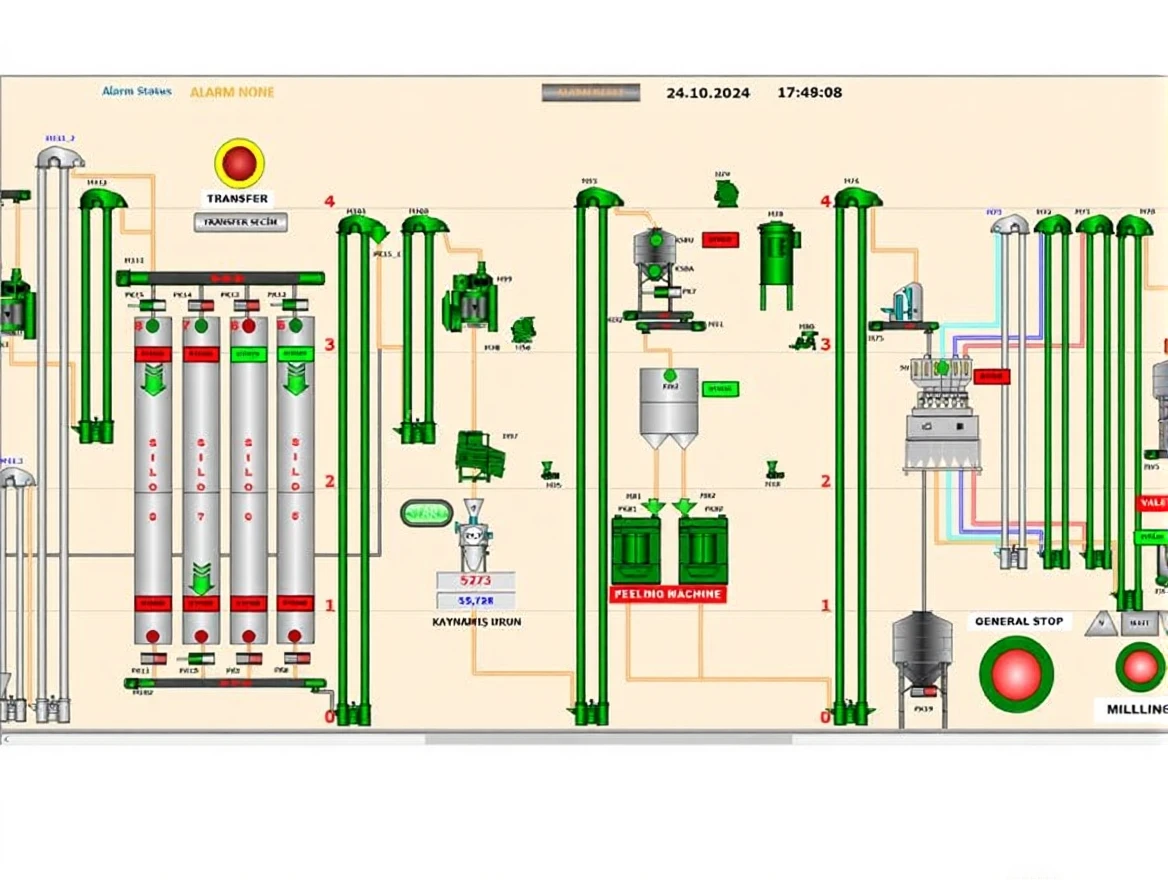

1. Introduction

Automation systems are used in bulgur production to increase efficiency, reduce error rates, and optimize workforce. Modern automation systems make production processes more reliable and efficient while minimizing energy consumption.

2. Automation System Components

The main automation components used in bulgur factories are as follows:

- PLC (Programmable Logic Controller): Provides automatic control of the entire system.

- SCADA System: Allows monitoring and analysis of data.

- Sensors and Actuators: Control the automatic operation of processes.

- Motor Drivers: Used to adjust motor speeds and powers.

- Industrial Weighing and Labeling Systems: Ensures products are weighed and labeled correctly.

- Safety and Emergency Systems: Ensures the safety of operators.

3. Automation in the Production Process

Bulgur production generally consists of the following stages:

- Cleaning and Screening: Cleaning the raw material and removing foreign substances.

- Boiling and Drying: Cooking and drying the wheat.

- Grinding at the Mill: Grinding the dried wheat to the appropriate fineness.

- Screening and Classification: Separating ground bulgur into different sizes.

- Packaging and Labeling: Packaging the products and preparing them for shipping.

4. Advantages of Automation

- Increased Efficiency: Speeds up processes and enables more production.

- Reduced Error Rate: Minimizes manual errors.

- Energy Efficiency: Reduces costs with less energy consumption.

- Traceability and Reporting: Allows real-time monitoring of the production process and data recording.

- Workforce Optimization: Enables more production with less workforce.

5. Conclusion and Evaluation

The use of automation systems in bulgur factories allows production processes to be managed more effectively and reliably. Modern automation solutions ensure quality standards, cost-effectiveness, and sustainable production.

Related products

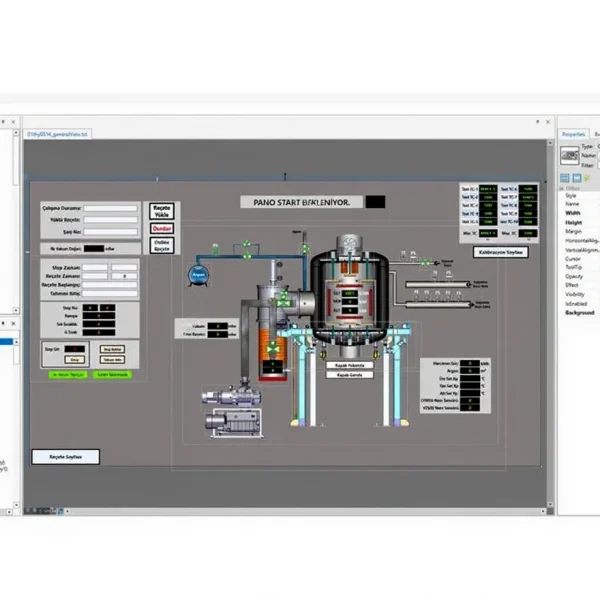

Eagleye Rsd Thermal Processing Furnace Industrial Automation Software

In stock

| Brand | 3E |

|---|---|

| Model Type |

Eagleye RSD |