Description

1. INTRODUCTION

- The importance of feed factory automation

- Productivity, quality, and cost advantages

- The role of automation in modern feed factories

2. FEED FACTORY PROCESSES AND AUTOMATION

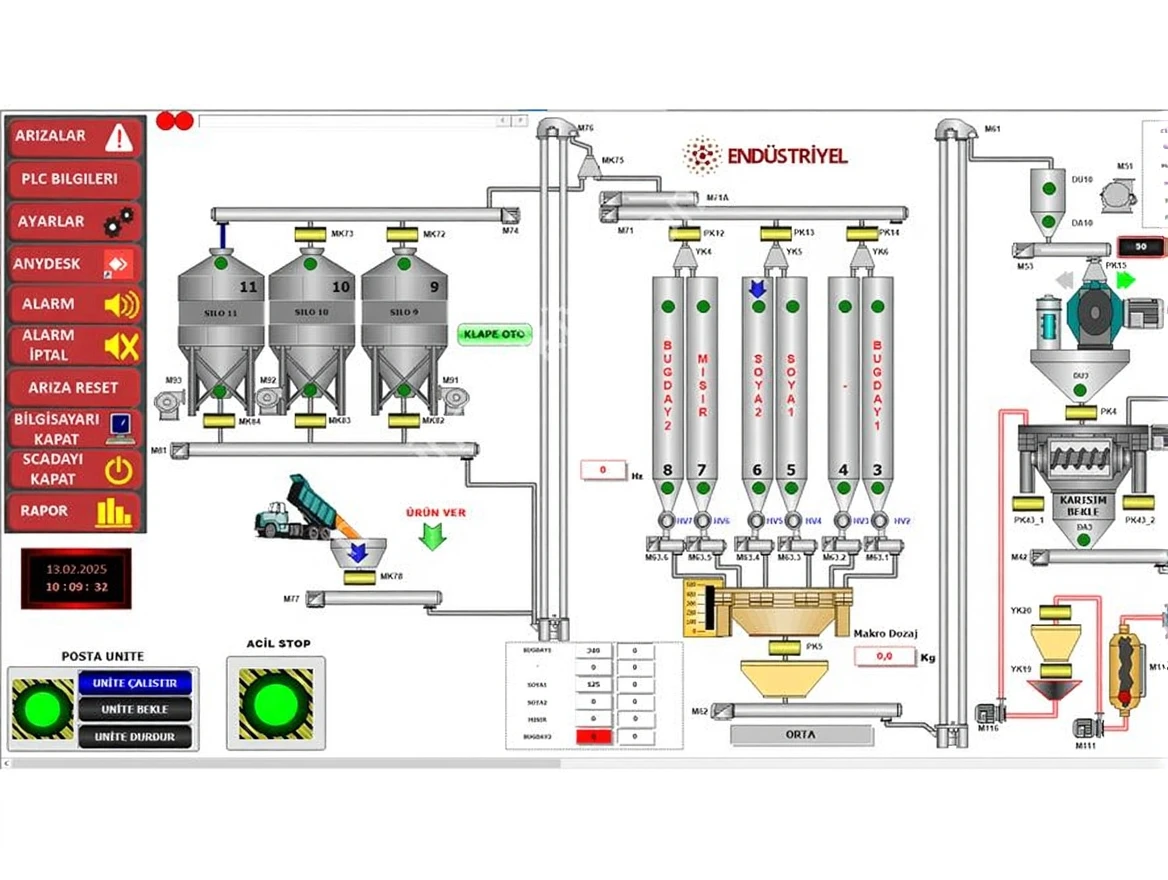

2.1. Receiving and Storage of Raw Materials

- Receipt of raw materials with conveying systems

- Quality control sensors and weighing systems

Silos and level control sensors

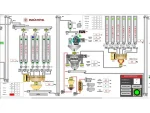

2.2. Conveying Systems

- Belt conveyors, elevators, and screw conveyors

- Automatic motor control and fault monitoring systems

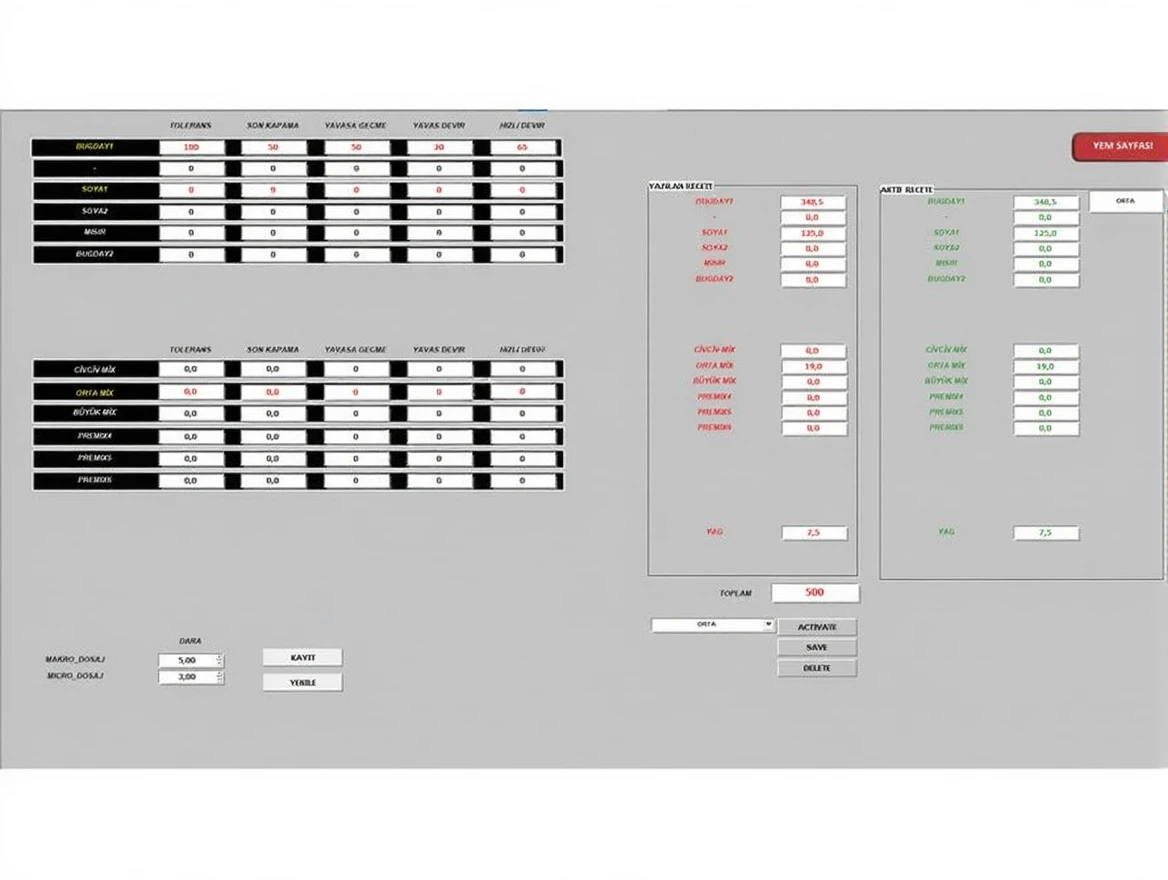

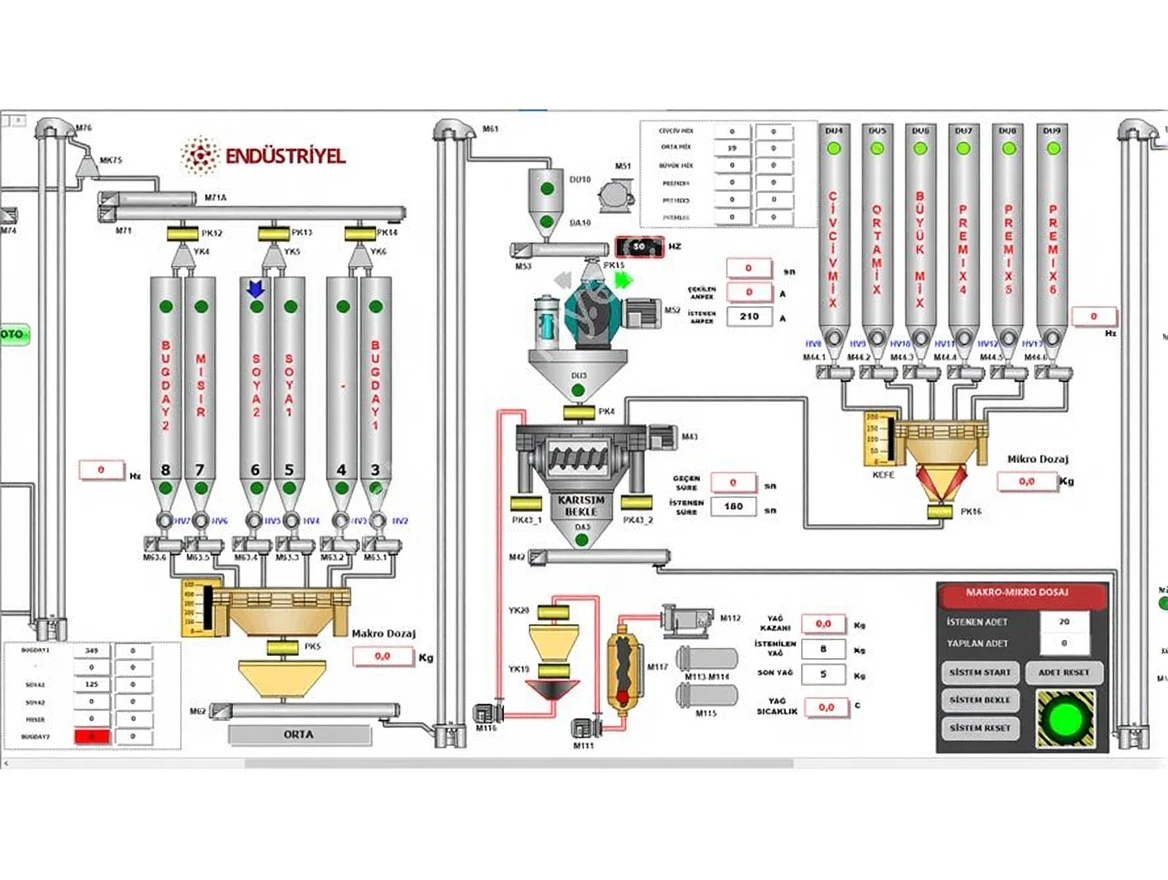

2.3. Grinding and Mixing at the Mill

- Use of roller mills and hammer mills

- Feed control with level sensors

- PLC controlled dosing systems

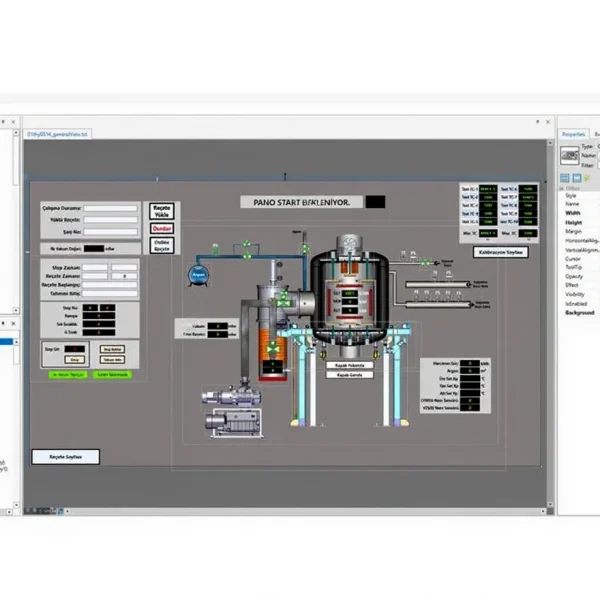

2.4. Pelleting Process

- Heating the mixture with steam and pelleting

- Automatic temperature and humidity control systems

2.5. Cooling and Screening

- Cooling of pellets to the appropriate temperature

- Separation of pellets with improper size by sieve systems

2.6. Packaging and Storage

- Automatic bagging and barcode systems

- Stock tracking and logistic automation

3. AUTOMATION TECHNOLOGIES

3.1. Use of PLC and HMI

- Programmable logic controllers (PLC)

- Easy control with operator panels (HMI)

3.2. SCADA and Data Tracking Systems

- Remote monitoring and control with SCADA

- Real-time data recording and reporting

3.3. Sensors and Actuators

- Level, temperature, humidity, and pressure sensors

- Motor drives (VFD) and pneumatic valves

3.4. AI and IoT Supported Systems

- IoT-based remote monitoring and predictive maintenance

- Increasing energy efficiency with machine learning

4. ADVANTAGES OF AUTOMATION

✅ Faster and more efficient production

✅ Lower energy and labor costs

✅ Better quality control and traceability

✅ Predictive maintenance and breakdown prevention

5. CONCLUSION AND FUTURE TRENDS

- Smart factory concept and fully automated solutions

Related products

Eagleye Rsd Thermal Processing Furnace Industrial Automation Software

In stock

| Brand | 3E |

|---|---|

| Model Type |

Eagleye RSD |